High-efficiency precise coal distributing system

A coal blending system and precise technology, applied in mixer accessories, mixers, solid fuels, etc., can solve the problems of inaccurate manual testing, low efficiency, large errors, etc., and achieve the effect of avoiding radiation of rays and ensuring a safe operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

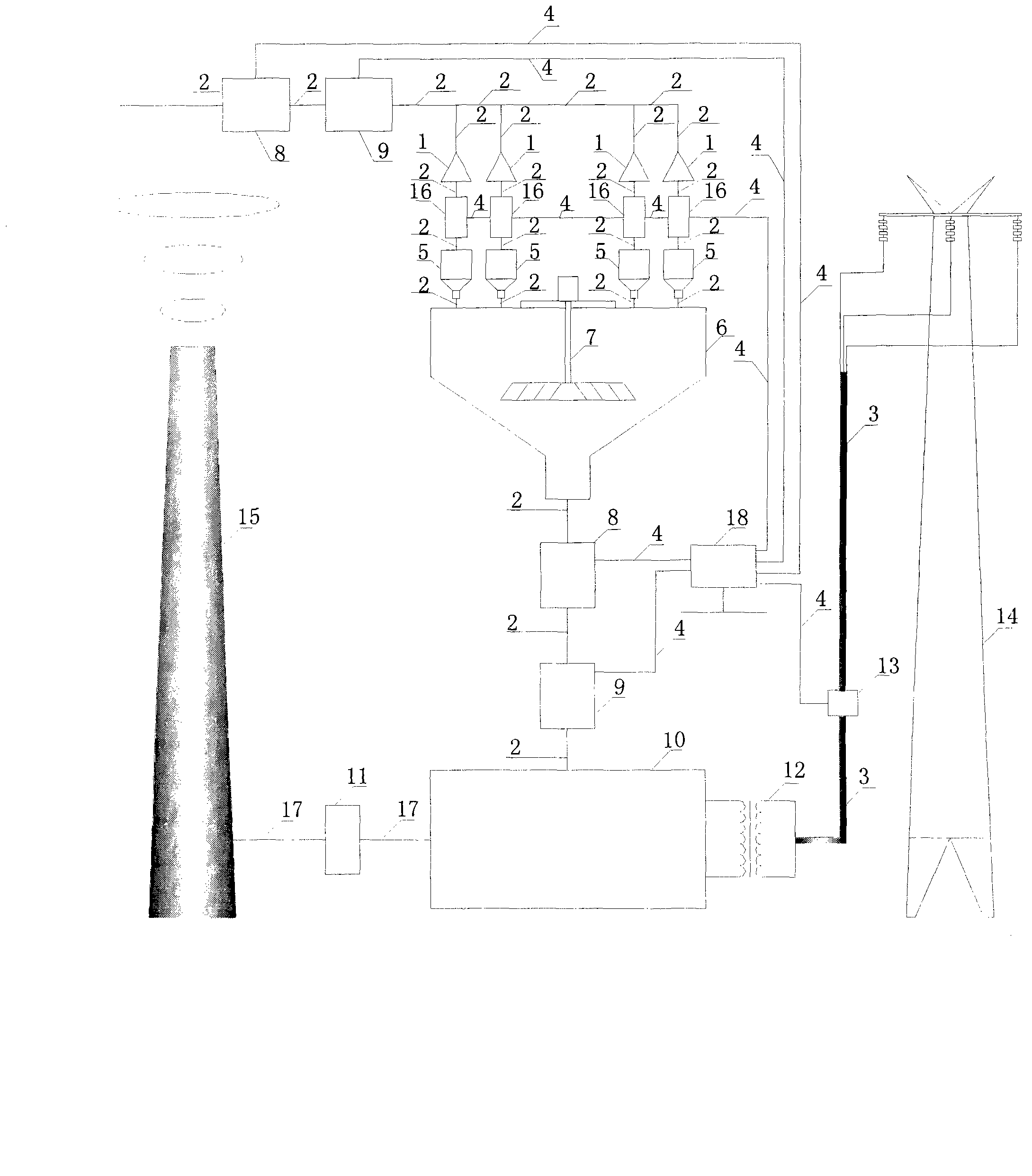

[0041]After the market selects and orders coal that is suitable for the coal blending requirements of thermal power plants, it passes through 2. the conveyor belt, passes through 8. the belt scale checks the weight; passes through 2. the conveyor belt, enters 9. the online full element analyzer; passes through 2. the conveyor belt, puts various Coal blending is transported to each 1. Coal storage bunker. During the process of transporting coal from coal blending to 1. Coal storage bin, 8. The belt scale checks the weight. 9. The online full-element analyzer will real-time analyze the weight of the various coals flowing through and their moisture, ash, and volatilization during this process. Minutes, calorific value, sulfur, hydrocarbon, nitrogen, ash melting point content and technical indicators are transmitted to the computer through the 4. communication line, and are recorded and stored one by one, so as to provide the original content parameters of each coal element for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com