Method for preparing methyl tert-butyl ether and alkane liquefied gas by dehydrogenating isobutane

A technology of methyl tert-butyl ether and isobutane, which is applied in the field of dehydrogenation of isobutane to produce methyl tert-butyl ether and alkane liquefied gas, which can solve the problem of high operating pressure in hydroprocessing process and absorbent recovery treatment Difficulty, high equipment material requirements, etc., to achieve the effect of low cost, uniform load, and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

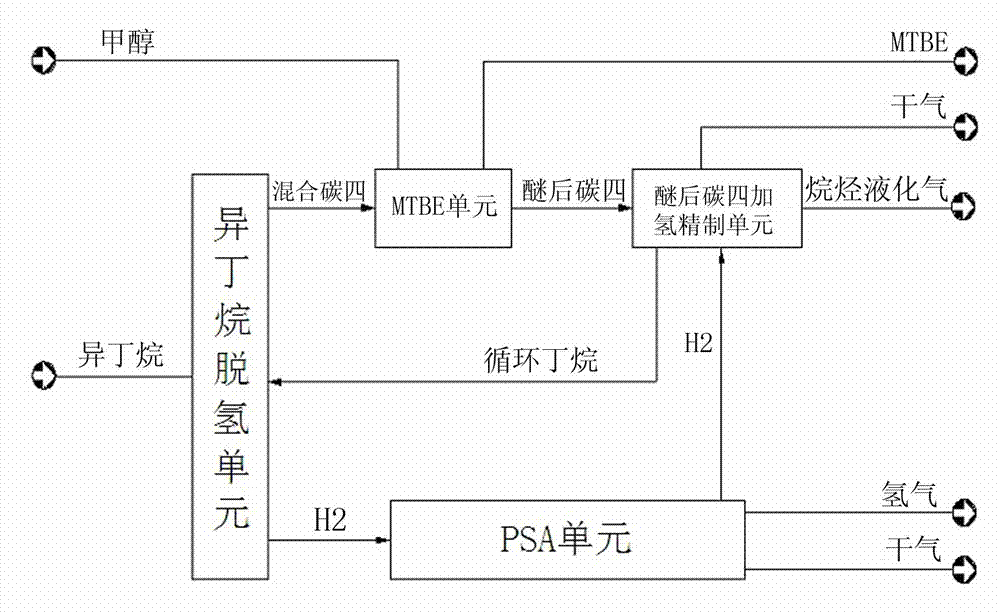

Method used

Image

Examples

preparation example Construction

[0021] ⑵. Preparation of methyl tert-butyl ether: the butane-containing isobutene mixture produced by isobutane dehydrogenation is mixed with methanol at a ratio of 1.03:1, and then enters the etherification reactor for etherification reaction at a temperature of 50 ℃~60℃, the pressure is 1.0kgf / cm2, after the reaction, the product is transported to the catalytic rectification tower, and a part of methanol is supplemented in the rectification tower to generate the product methyl tert-butyl ether; the top of the catalytic rectification tower is extracted The post-ether C4 contains a small amount of reaction residual methanol and is sent to the methanol water washing tower for water washing, and the liquefied gas at the top of the washing tower is removed from the methanol to form ether, and the C4 is transported to the post-ether C4 hydrogenation unit;

[0022] ⑶. Hydrogenation of C4 after ether: heat exchange between C4 after ether and the hydrogenation product, after heat exch...

Embodiment

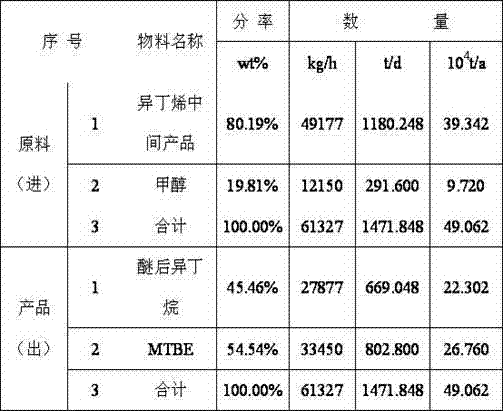

[0027] total material balance

[0028]

[0029] Material balance of isobutane dehydrogenation unit

[0030]

[0031] MTBE unit material balance sheet

[0032]

[0033] Material Balance Sheet of C4 Hydrotreating Unit after Ether

[0034]

[0035] PSA Unit Material Balance Sheet

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com