Preparation method of modified whey protein powder

The technology of whey protein powder and whey protein is applied in the field of preparation of modified whey protein powder, which can solve the problems of high energy consumption for raw material pretreatment, long modification time, etc., so as to improve the acylation speed and improve the gelation rate. The effect of sex, simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

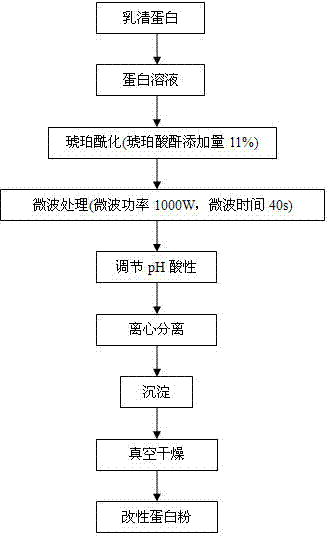

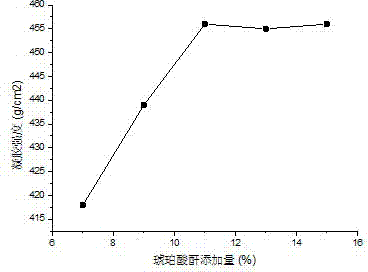

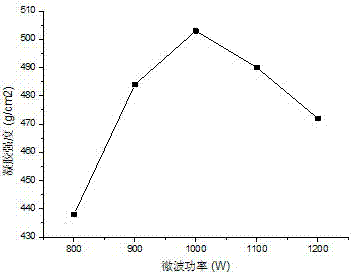

[0018] A preparation method of modified whey protein powder, the method comprising the following steps: (1) dissolving whey protein in water to prepare a 7% whey protein solution; (2) adding a certain amount of Succinic anhydride is succinylated, and the amount of succinic anhydride added is 7-15% of the mass of the protein solution; (3) the succinylated protein solution is adjusted to pH 8, and then it is subjected to microwave treatment, and the microwave Power 800-1200W, microwave time 20-60s; (4) Adjust the pH of the protein solution after microwave treatment to 4, stir for 30 minutes, centrifuge at 4000r / min for 20 minutes, and take the precipitated part; (5) Vacuum dry the precipitated part Modified whey protein powder.

[0019] The preferred amount of succinic anhydride added is 10.9% of the protein solution mass.

[0020] The preferred parameters of the microwave treatment are: microwave power 1049.78 W, microwave time 44.97s.

[0021]

experiment example

[0022] Experimental example Screening experiments of the optimal parameters of succinic anhydride addition amount and microwave treatment process conditions

[0023] 1 Materials and methods

[0024] 1.1 Materials and reagents

[0025] Whey Protein Hargaco

[0026] Succinic Anhydride Hangzhou Zhongxiang Chemical Co., Ltd.

[0027] 1.2 Main instruments and equipment

[0028] TA Texture Analyzer SMS UK;

[0029] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0030] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0031] Precision Electric Mixer Jiangsu Jintan City Ronghua Instrument Manufacturing Co., Ltd.

[0032] Ultrasonic Cleaner Yuyao Dongfang Electrical Instrument Factory

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com