Sole material for sports shoes for body-building and mountaineering and preparation method thereof

A technology for sole materials and sports shoes, which is applied in the field of composite materials and the preparation of the materials, can solve the problems of low sole elasticity and reduced comfort, and achieve the effects of good elasticity, improved service life and broad market application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A sports shoe sole material for fitness and mountaineering, the components and their mass percentages in the formula are:

[0033] Natural rubber, 30%;

[0034] SBR, 30%;

[0035] Aramid staple fiber, 3%;

[0036] Carbon black, 12%;

[0037] White carbon black (SiO 2 ), 10%;

[0038] Stearic acid (SA), 2%;

[0040] Disilane tetrasulfide (Si-69), 3%;

[0041] Sulfur (S), 6%.

[0042] 1) Step 1, ingredients according to the above recipe.

[0043] 2) In step 2, mix the prepared materials on a special mixer for short-fiber rubber mixing. The specific mixing process and process conditions are as follows:

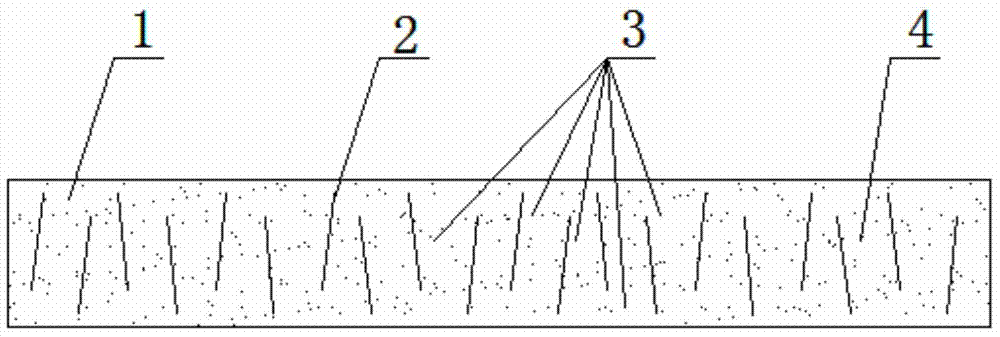

[0044] First add natural rubber and styrene-butadiene rubber 1, then add aramid staple fiber 2, all components except natural rubber and styrene-butadiene rubber 1, aramid staple fiber 2 and sulfur 4 are added in two times, and finally add sulfur 4 , to prepare the rubber compound.

[0045] The mixing process conditions are: rotor ...

Embodiment 2

[0054] A sports shoe sole material for fitness and mountaineering, the components and their mass percentages in the formula are:

[0055] Natural rubber, 30%;

[0056] Styrene butadiene rubber, 26%;

[0057] Polyester staple fiber, 2%;

[0058] Carbon black, 15%;

[0059] White carbon black (SiO 2 ), 12%;

[0060] Stearic acid (SA), 2.5%;

[0062] Disilane tetrasulfide (Si-69), 2.5%;

[0063] Sulfur (S), 5%.

[0064] 1) Step 1, ingredients according to the above recipe.

[0065] 2) In step 2, mix the prepared materials on a special mixer for short-fiber rubber mixing. The specific mixing process and process conditions are as follows:

[0066] Add natural rubber and styrene-butadiene rubber 1 first, then polyester staple fiber 2, all components except natural rubber and styrene-butadiene rubber 1, polyester staple fiber 2 and sulfur 4 are added in two times, and finally sulfur 4 is added , to prepare the rubber compound.

[0067] The mixi...

Embodiment 3

[0076] A sports shoe sole material for fitness and mountaineering, the components and their mass percentages in the formula are:

[0077] Natural rubber, 25%;

[0078] SBR, 35%;

[0079] Nylon staple fiber, 1%;

[0080] Carbon black, 14%;

[0081] White carbon black (SiO 2 ), 12%;

[0082] Stearic acid (SA), 2%;

[0083] Zinc oxide (ZnO), 3%;

[0084] Disilane tetrasulfide (Si-69), 3%;

[0085] Sulfur (S), 5%.

[0086] 1) Step 1, according to the above recipe ingredients:

[0087] 2) In step 2, mix the prepared materials on a special mixer for short-fiber rubber mixing. The specific mixing process and process conditions are as follows:

[0088] First add natural rubber and styrene-butadiene rubber 1, then add nylon staple fiber 2, add all components 3 except natural rubber and styrene-butadiene rubber 1, nylon staple fiber 2 and sulfur 4 in two times, and finally add sulfur 4 to prepare Get the rubber compound.

[0089] The mixing process conditions are: rotor speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com