A high tear-resistant cable sheathing compound

A cable sheath material, high resistance technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of expensive preparation cost, difficult rubber mixing, poor reinforcement effect, etc., to improve tear strength and increase outdoor use Good effect of time, durability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

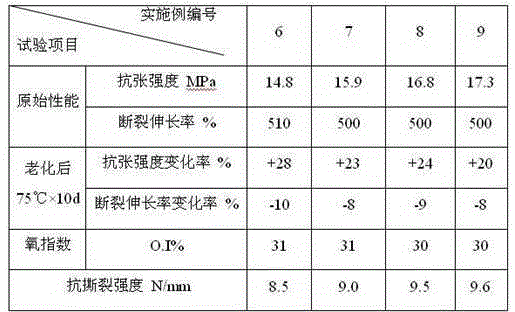

Examples

Embodiment 1

[0041] A high tear resistant cable sheathing material consisting of, by weight:

[0042] Chlorinated polyethylene 100 parts

[0043] Vulcanizing agent 2 parts

[0044] Vulcanization accelerator 2 parts

[0045] Active agent 4 parts

[0046] Softener 22 parts

[0047] 2 parts processing aid

[0048] Stabilizer 6 parts

[0049] Antioxidant 2.5 parts

[0050] 8 parts of flame retardant

[0051] White carbon black 15 parts

[0052] Qiangwei Powder 25 copies

[0053] Calcium carbonate 10 parts

[0054] 0.6 part of pigment.

Embodiment 2

[0056]A high tear resistant cable sheathing material consisting of, by weight:

[0057] Chlorinated polyethylene 100 parts

[0058] 2.5 parts of vulcanizing agent

[0059] 1.5 parts of vulcanization accelerator

[0060] Active agent 5 parts

[0061] Softener 20 parts

[0062] Processing aid polyethylene wax 3 parts

[0063] Stabilizer 4 parts

[0064] Antioxidant 3 parts

[0065] 6 parts of flame retardant

[0066] White carbon black 18 parts

[0067] Qiangwei powder 20 parts

[0068] Calcium carbonate 12 parts

[0069] 0.5 part of pigment.

Embodiment 3

[0071] A high tear resistant cable sheathing material consisting of, by weight:

[0072] Chlorinated polyethylene 100 parts

[0073] Vulcanizing agent 5 parts

[0074] 3 parts vulcanization accelerator

[0075] Active agent 10 parts

[0076] Softener 25 parts

[0077] Processing aid polyethylene wax 8 parts

[0078] Stabilizer 10 parts

[0079] Antioxidant 5 parts

[0080] 10 parts of flame retardant

[0081] White carbon black 30 parts

[0082] Qiangwei Powder 30 copies

[0083] Calcium carbonate 25 parts

[0084] 0.8 part of pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com