Low-smoke halogen-free flame-retardant anti-aging cable material for cables

An aging-resistant, cable material technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as large changes in mechanical properties, unsatisfactory aging resistance, property damage, etc. Aging resistance, effect of low smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

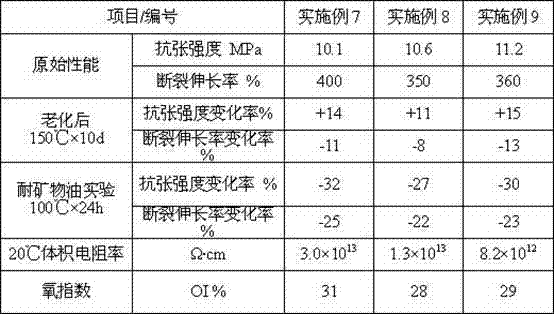

Examples

Embodiment 1

[0038] A low-smoke, halogen-free, flame-retardant and aging-resistant cable material for cables. By weight, the composition of the material includes:

[0039] EPDM rubber 20 parts

[0040] EVM 60 copies

[0041] Vulcanizing agent 2.5 parts

[0042] 3 parts vulcanizing agent

[0043] Anti-aging agent 3 parts

[0044] 15 parts plasticizer

[0045] 0.5 parts of coupling agent

[0046] Reinforcing agent 20 parts

[0047] Filler 20 parts

[0048] Flame retardant 56 parts.

Embodiment 2

[0050] A low-smoke, halogen-free, flame-retardant and aging-resistant cable material for cables. The material is composed of:

[0051] 30 parts of EPDM rubber

[0052] EVM 50 copies

[0053] Vulcanizing agent 2.8 parts

[0054] Vulcanizing agent 1.5 parts

[0055] Anti-aging agent 8 parts

[0056] Plasticizer 10 parts

[0057] Coupling agent 1.0 part

[0058] Reinforcing agent 15 parts

[0059] Filler 26 parts

[0060] 50 parts of flame retardant.

Embodiment 3

[0062] A low-smoke, halogen-free, flame-retardant and aging-resistant cable material for cables. The material is composed of:

[0063] EPDM rubber 50 parts

[0064] EVM 70 copies

[0065] Vulcanizing agent 5 parts

[0066] Vulcanizing agent 5 parts

[0067] Anti-aging agent 3 parts

[0068] Plasticizer 25 parts

[0069] 1.5 parts of coupling agent

[0070] Reinforcing agent 25 parts

[0071] Filling agent 40 parts

[0072] 65 parts of flame retardant.

[0073] The flame retardant described in the present invention is a low-smoke, halogen-free flame retardant.

[0074] The reinforcing agent of the invention is carbon black, which is cheap, stable in chemical properties, good in reinforcing effect, and significantly improves the mechanical properties of the product.

[0075] The filler described in the present invention is calcined clay. Stable chemical properties, smooth appearance of extruded or calendered products, good heat resistance, acid and alkali resistance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com