Low friction emulsifying acid liquid for fracturing acidification, and application thereof

A fracturing acidification and low-friction technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting the popularization and application of emulsified acid, poor temperature resistance and shear resistance, and difficult liquid flowback, etc. Achieve excellent drainage performance, low construction friction, and excellent retarding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Slowly add 0.3 part of ODEA, 0.1 part of octadecyl primary amine, 0.2 part of n-octanoic acid, 1 part of drag reducer to diesel oil stirred at low speed, and stir thoroughly for 30 minutes to obtain an oil phase; add 1.5 parts of acid to 28% concentrated hydrochloric acid Liquid multi-effect additive, 1 part of drainage aid, fully stirred and circulated for 30 minutes to obtain the acid phase.

[0018] Emulsifying acid preparation: Slowly add 70 parts of acid phase liquid to 30 parts of oil phase in low-speed stirring circulation. After all the acid phase liquid is added, circulate at low speed for 30 minutes to fully emulsify.

[0019] The prepared emulsified acid solution is directly pumped into the fracturing manifold by a pump truck on site for acid fracturing construction.

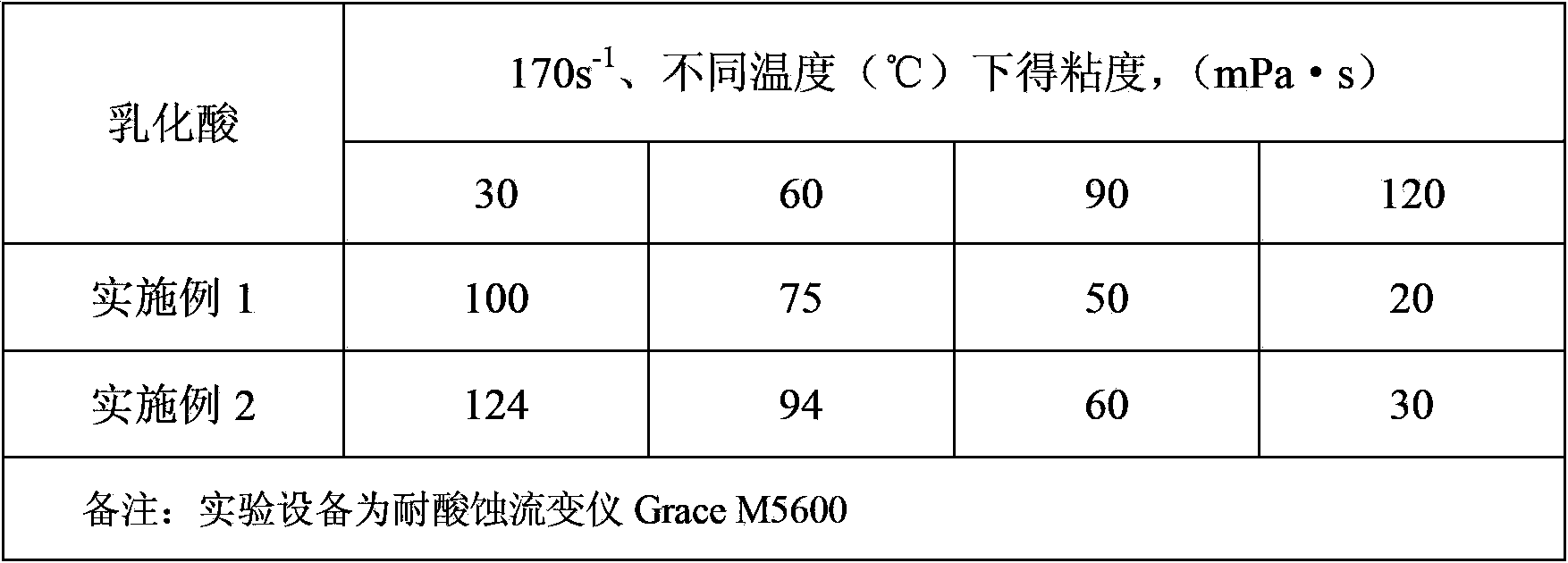

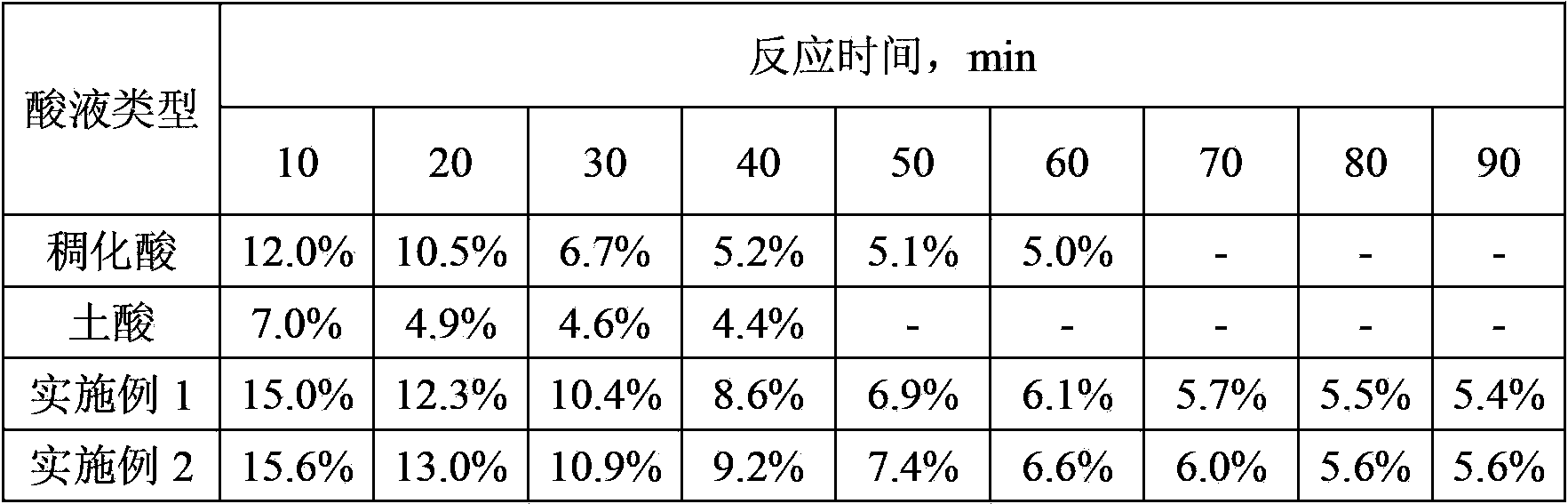

[0020] Example 1 A low-friction emulsified acid system for fracturing and acidizing is suitable for acid fracturing of carbonate rock reservoirs at 60°C to 80°C.

Embodiment 2

[0022] Slowly add 0.4 parts of ODEA, 0.2 parts of octadecyl primary amine, 0.3 parts of n-octanoic acid, 2 parts of drag reducer to diesel oil stirred at low speed, and stir thoroughly for 30 minutes to obtain an oil phase; add 2 parts of acid to 28% concentrated hydrochloric acid Liquid multi-effect additives, 2 parts of drainage aids, fully stirred and circulated for 30 minutes to obtain the acid phase.

[0023] Emulsifying acid preparation: Slowly add 70 parts of acid phase liquid to 30 parts of oil phase in low-speed stirring circulation. After all the acid phase liquid is added, circulate at low speed for 30 minutes to fully emulsify.

[0024] The prepared emulsified acid solution is directly pumped into the fracturing manifold by a pump truck on site for acid fracturing construction.

[0025] Example 2 A low-friction emulsified acid system for fracturing and acidizing is suitable for acid fracturing of carbonate reservoirs at 80°C to 100°C.

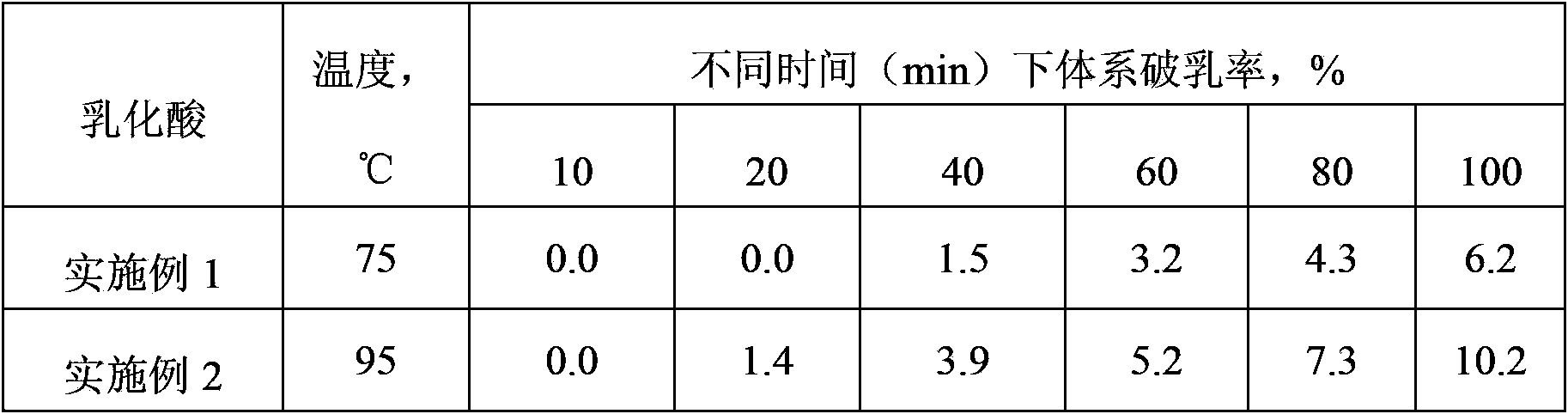

[0026] The performance adva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com