Method for preparing natural gas hydrate

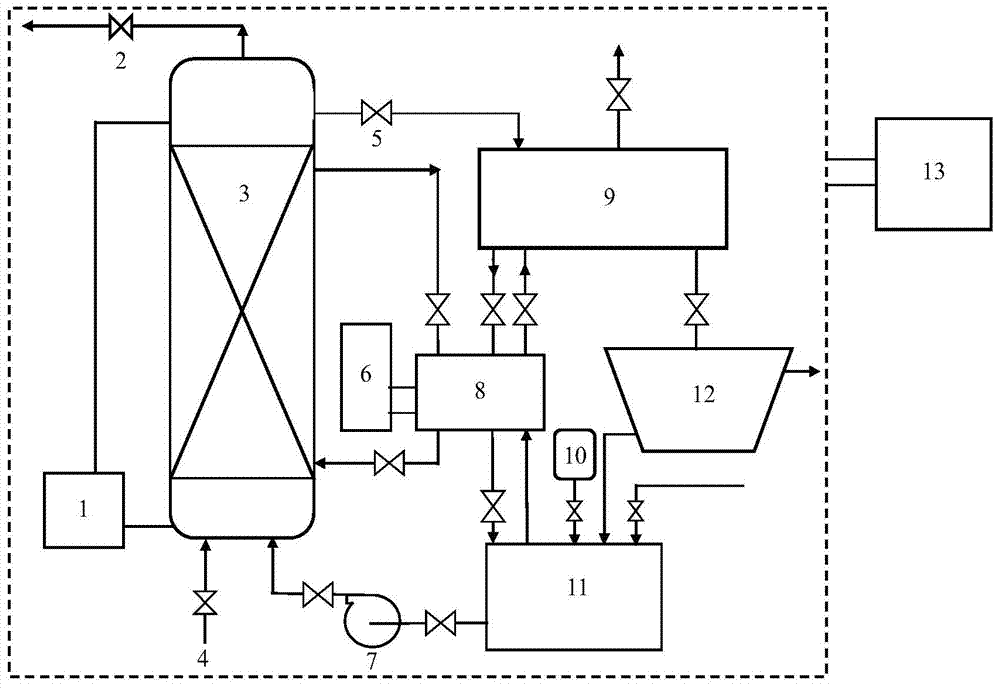

A hydrate and natural gas technology, applied in chemical methods, chemical instruments and methods, and gas fuels for reacting liquid and gas media, can solve problems such as poor economy, low gas content of hydrates, and lack of industrialization , to increase the gas-liquid contact area, promote rapid generation, and increase the gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

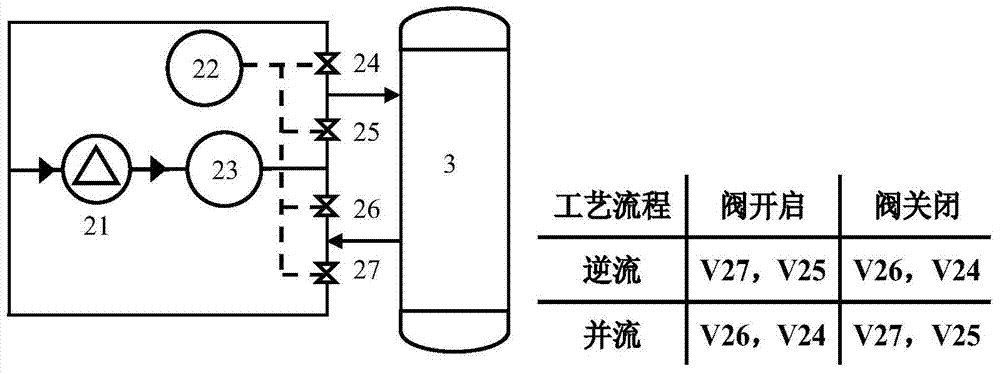

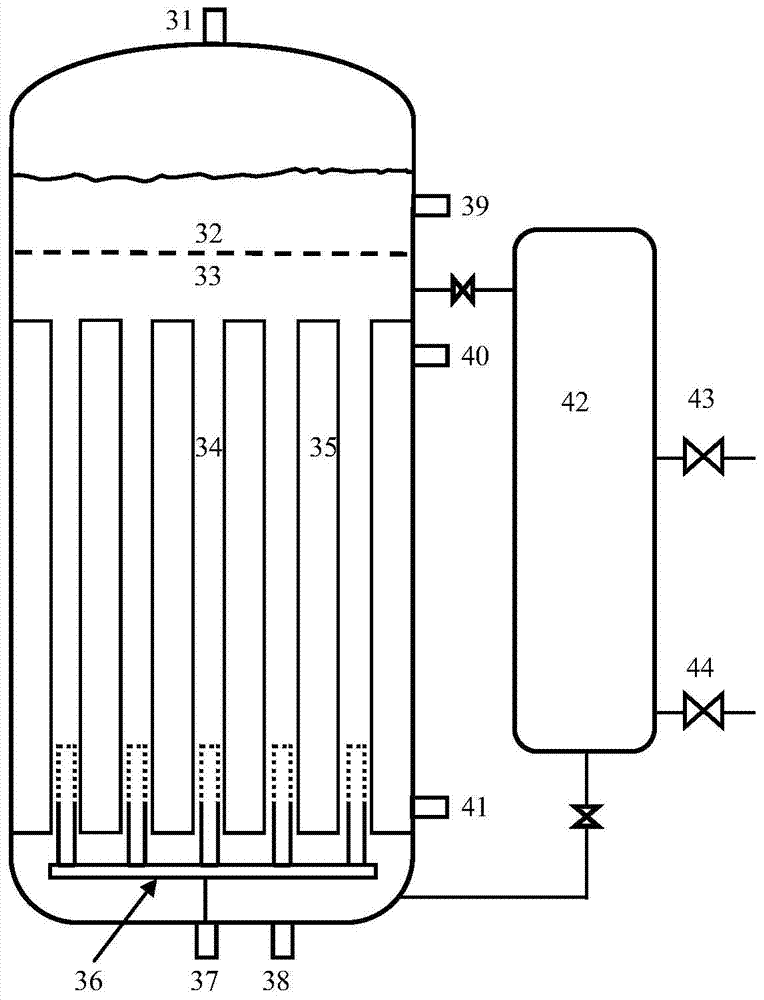

Method used

Image

Examples

Embodiment 1

[0073]Start the cold storage unit 6 and the refrigeration unit 8, supply chilled water to the heat exchange mechanism set in the water tank 11 and the intermediate storage tank 9, and control the temperature in the whole multi-stage bubbling reactor 3 at 4°C; start the water pump 7 and The central control system 13 pumps water equipped with additives into the reaction unit of the reactor. When the water level at the top of the reactor exceeds the clapboard and reaches the designated liquid level, open the discharge valve 5 at the outlet of the bypass pipe, adjust the opening degree of the valve and the displacement of the delivery pump 7, so that the water passes through the discharge valve 5, the intermediate storage tank 9, The separator 12 and the water tank 11 form a stable water cycle; after that, the natural gas enters the tube side of the multi-stage bubbling reactor 3 through the flow regulating valve and the nozzle, and the pressure is stable at 7MPa; then the cold sto...

Embodiment 2

[0076] Adopt the technological process of embodiment 1, but the pressure in the reaction tower is 8.0MPa, and the temperature in the tower is 5 ℃. The milky white hydrate slurry was prepared by reaction, and the gas content of natural gas hydrate reached 88.1V / V.

Embodiment 3

[0078] Adopt the technological process of embodiment 1, but the pressure in the reaction tower is 8.13MPa, and the temperature in the tower is 4 ℃. The milky white hydrate slurry was prepared by reaction, and the gas content of natural gas hydrate reached 110.0V / V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com