Preparation method of castor oil and castor oil prepared through same

A castor oil and castor bean technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of high energy consumption, increased cost of castor oil refining treatment, etc., and achieve high extraction rate, low cost, and short time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

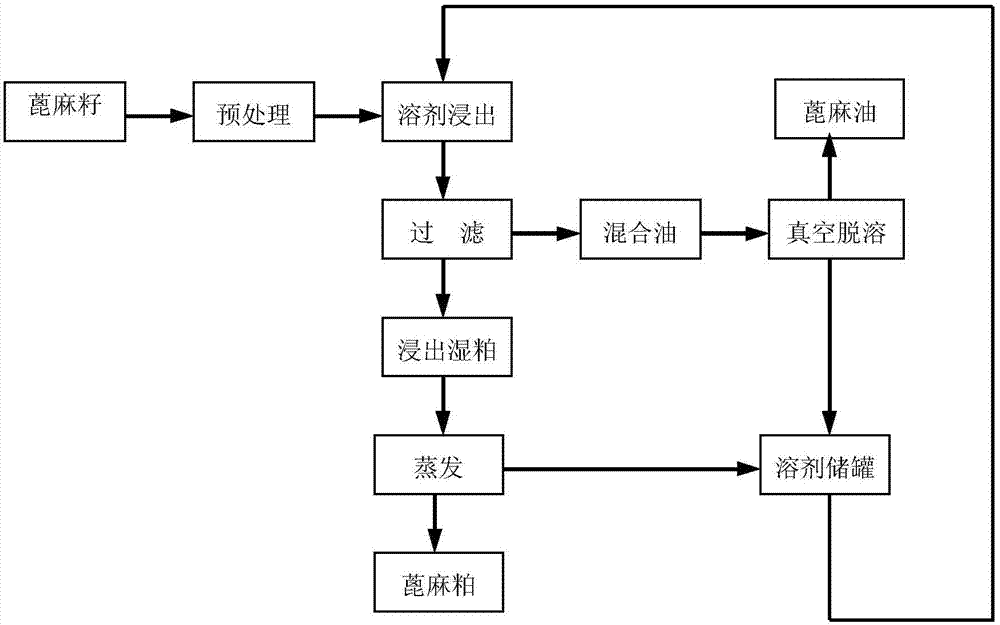

Method used

Image

Examples

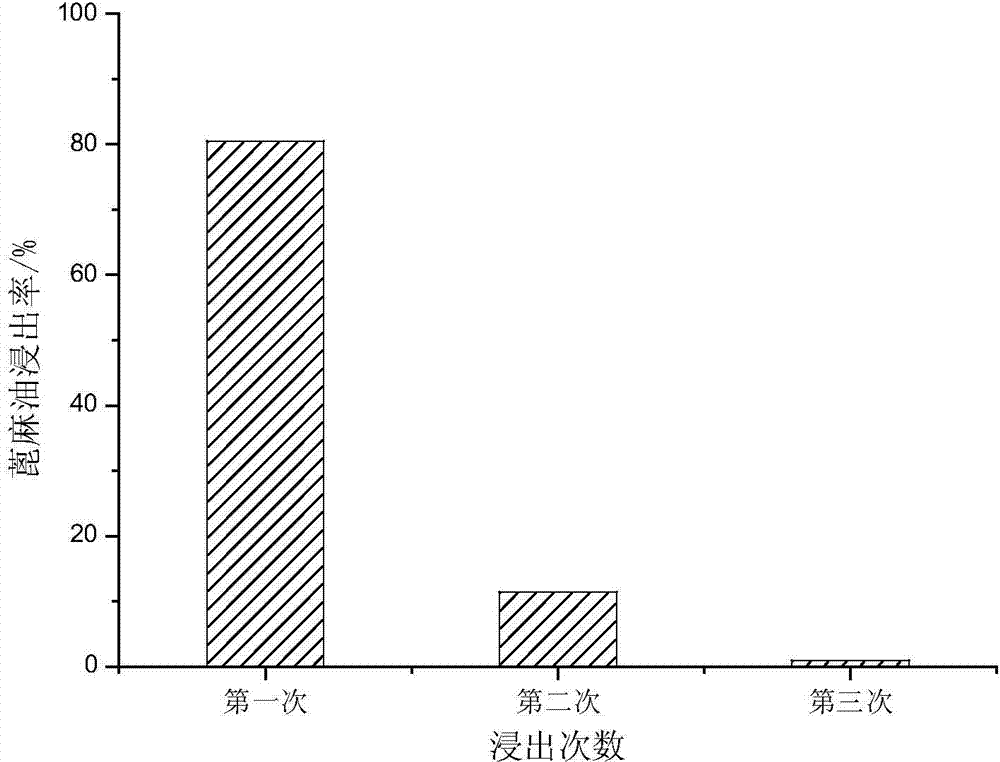

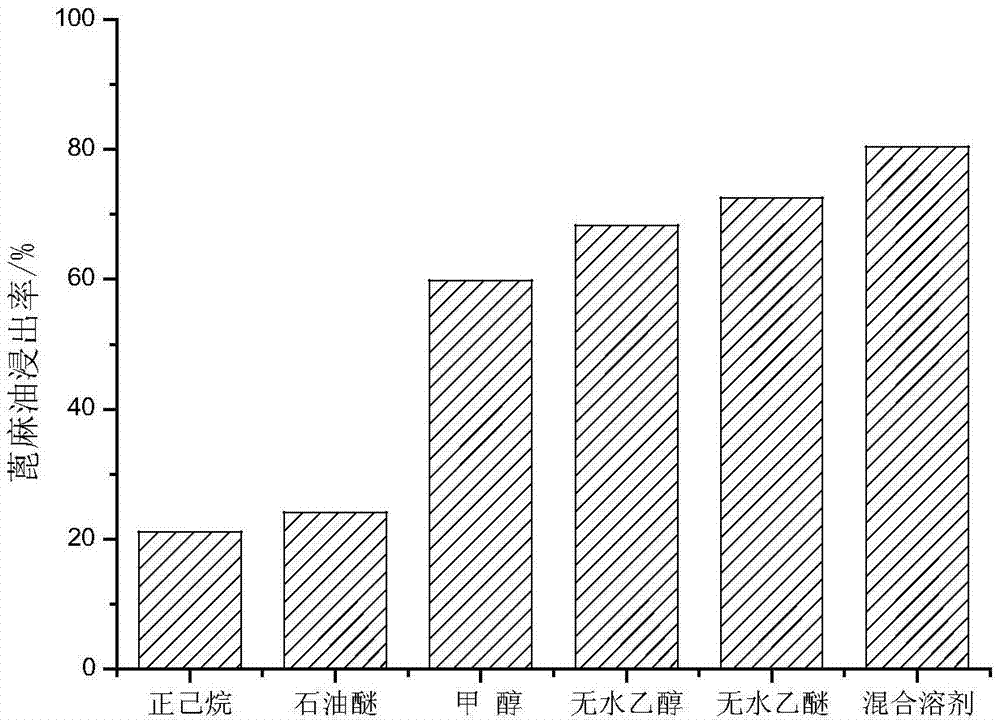

Embodiment 1

[0066] (1) Pretreatment of castor bean seeds at 0.5Kg: removing impurities and pests, shelling, drying and crushing to obtain castor bean powder;

[0067] (2) Put the castor bean powder obtained in step 1 into a container, add 1.5L of petroleum ether-diethyl ether mixed solvent with a volume ratio of 9:1 (material-to-liquid ratio 1:3); stir and extract with an electric stirrer at room temperature 1 time, 60min extraction; the power of the electric stirrer is 50W, and the speed is 2rpm;

[0068] (3) Filtering and separating the solid-liquid mixture obtained in step 2 to obtain mixed oil and castor meal; the mixed oil is vacuum desolventized to obtain 0.1557Kg castor oil with a leaching rate of 58.05%.

Embodiment 2

[0070] Castor bean 0.5Kg, using a preparation method similar to Example 1; the difference lies in:

[0071] The volume ratio of petroleum ether and ether in the mixed solvent is 7:3, and the rotating speed of the electric stirrer is 4 rpm.

[0072] The castor oil 0.2158Kg was prepared, and the extraction rate was 80.43%.

Embodiment 3

[0074] Castor bean 0.5Kg, using a preparation method similar to Example 1; the difference lies in:

[0075] The volume ratio of petroleum ether and ether in the mixed solvent is 5:5, and the rotating speed of the electric stirrer is 5 rpm.

[0076] 0.1903kg castor oil was prepared, and the leaching rate was 70.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com