Freeze-thaw cycle testing machine

A freeze-thaw cycle and testing machine technology, applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of increased laboratory noise emissions, high maintenance costs, waste of power, etc., to achieve strong adaptability to the working environment and reduce energy consumption , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

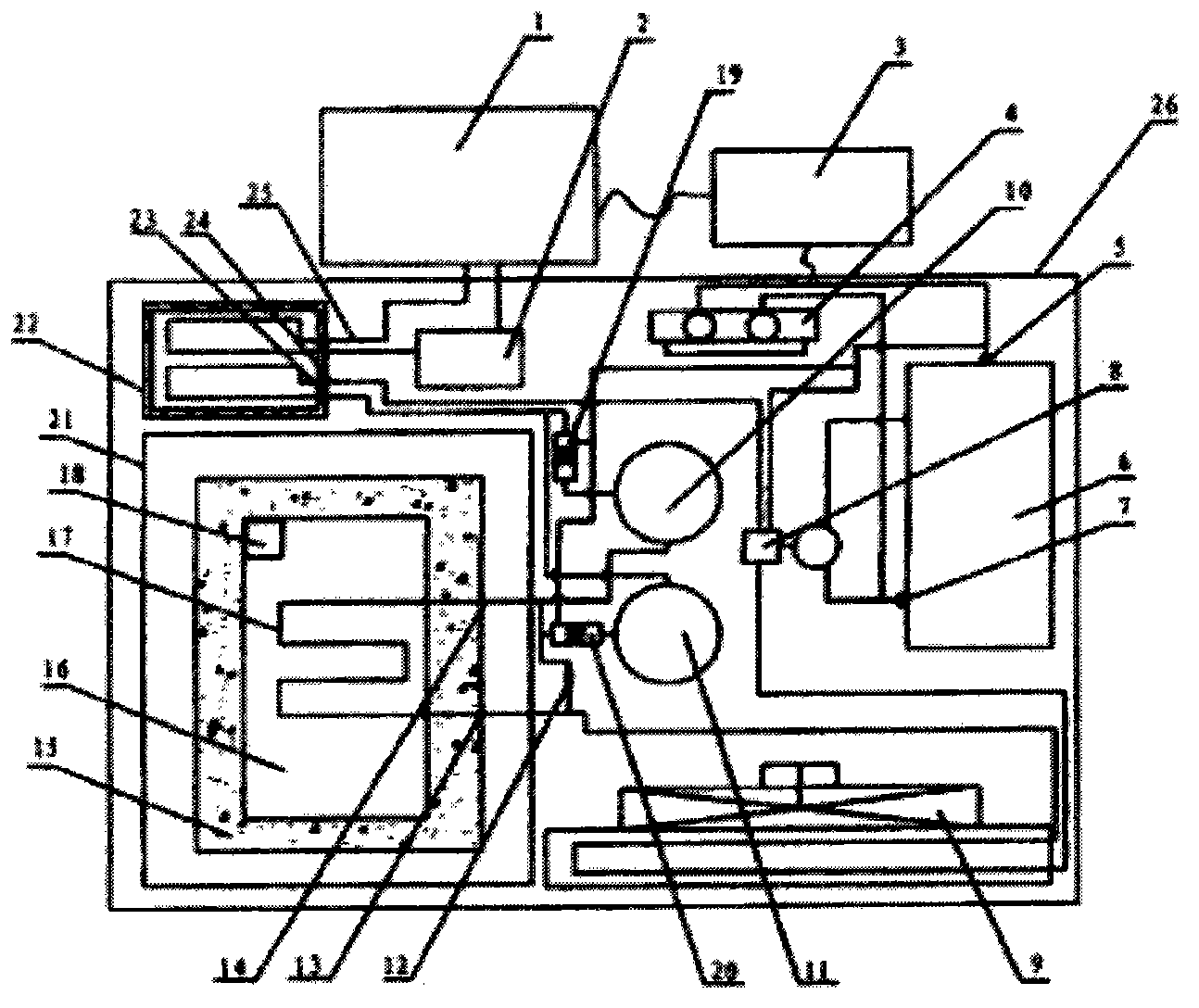

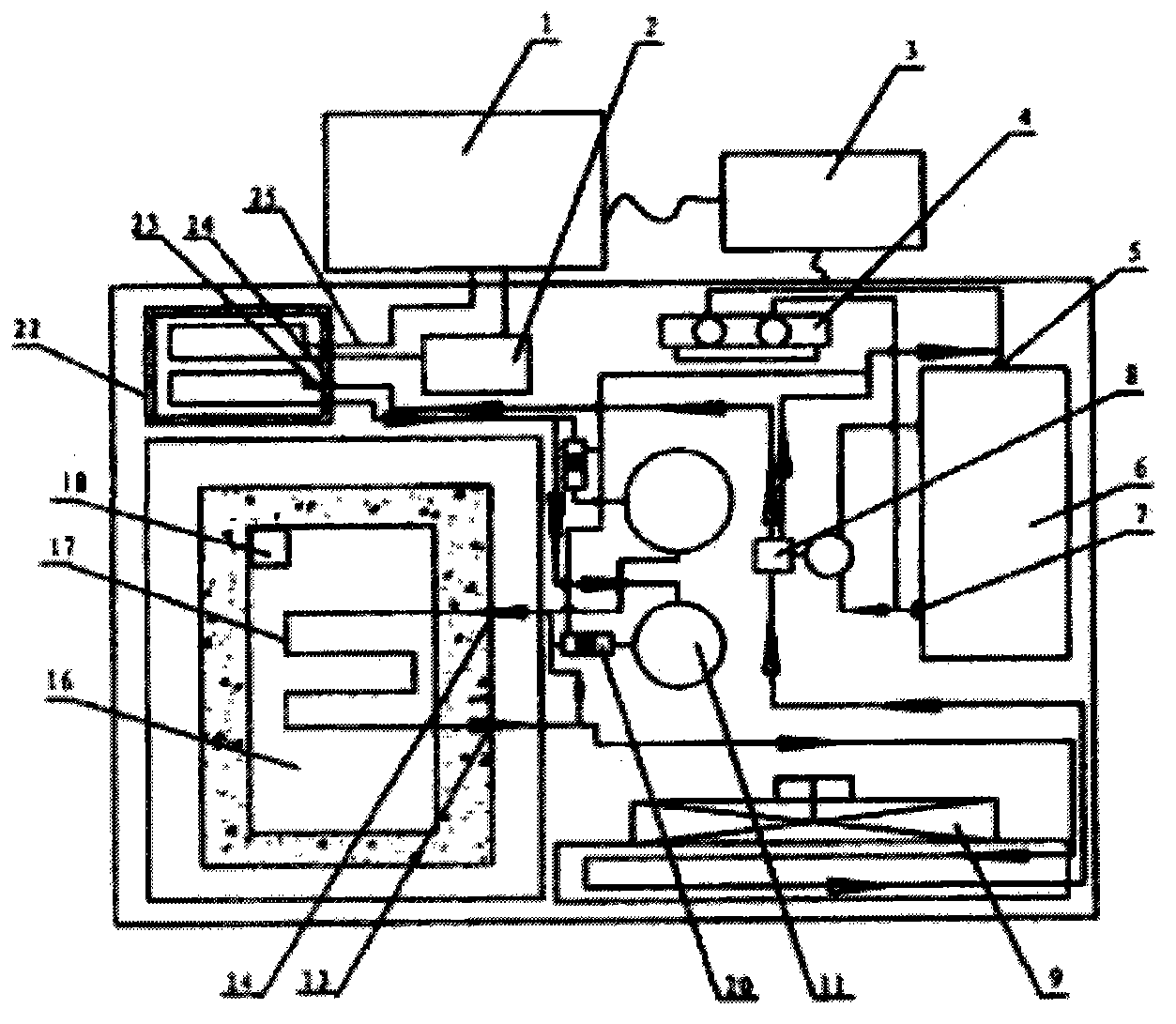

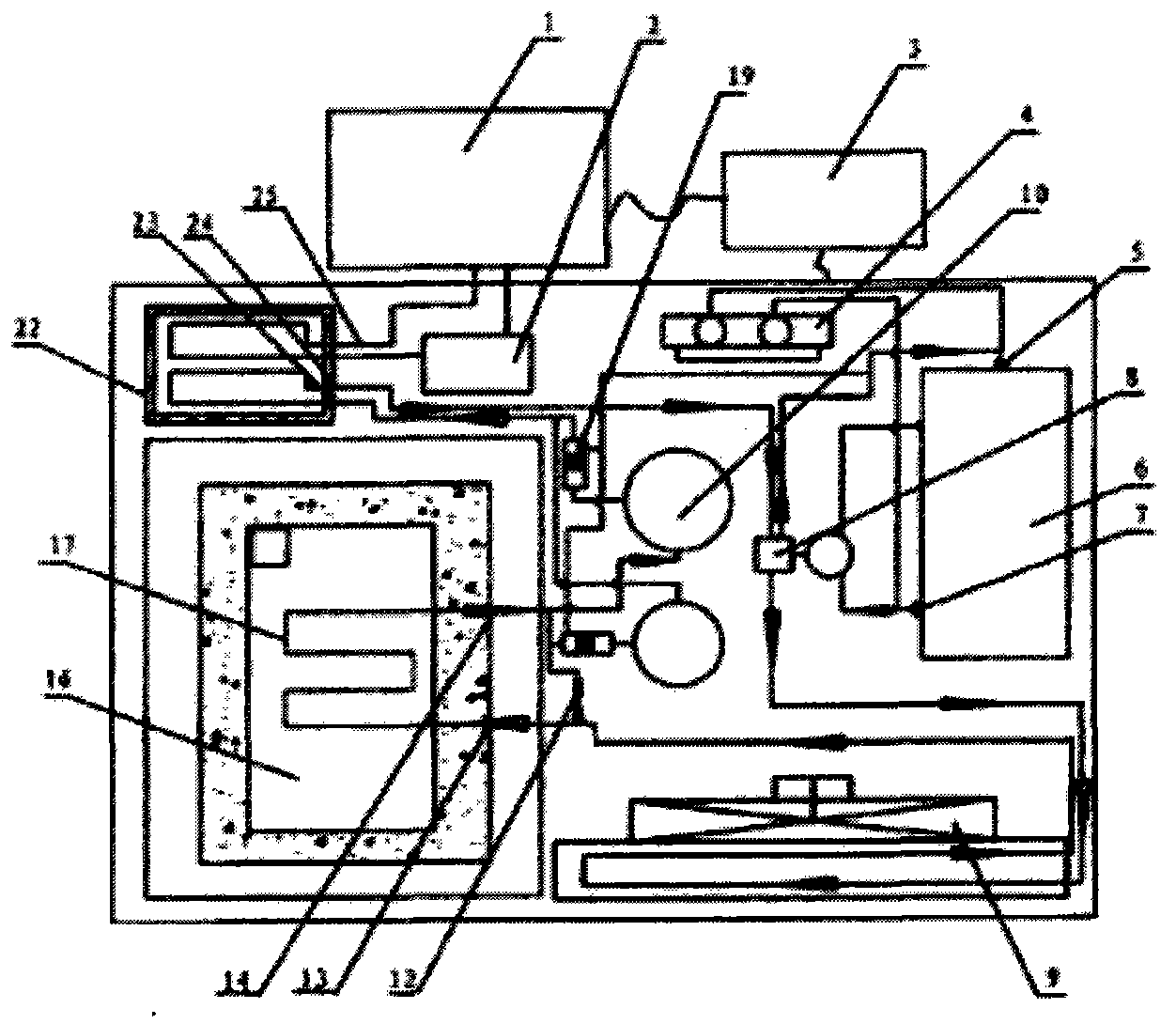

[0016] Such as figure 1 As shown, the freeze-thaw cycle testing machine of the present invention includes a cooling and heat exchange unit 26, a test piece box 1 and a control device 3.

[0017] The cooling and heat exchange unit 26 includes a refrigerant compressor 6, a plate heat exchanger 22, a fan heat exchanger 9, a pressure protection device 4 and an energy storage device. The refrigerant compressor 6, the plate heat exchanger 22, the fan heat exchanger 9 and the energy storage device are respectively fixed on the base of the cooling and heat exchange group 26 box body, and the two interfaces of the pressure protection device 4 are respectively connected to the refrigerant compressor. On the high-pressure port 7 and low-pressure port 5 of the machine, the blue controls the pressure at both ends of the refrigerant compressor 6, and converts the pressure signal into an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com