Module flow balancing water channel used for direct current converter valve

A DC converter valve, flow equalization technology, applied in circuits, electrical components, electro-solid devices, etc., can solve the problems of reduced thyristor availability, reduced insulation level, poor temperature consistency, etc., to achieve good flow equalization performance , the flow resistance is consistent, and the effect of avoiding the increase of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

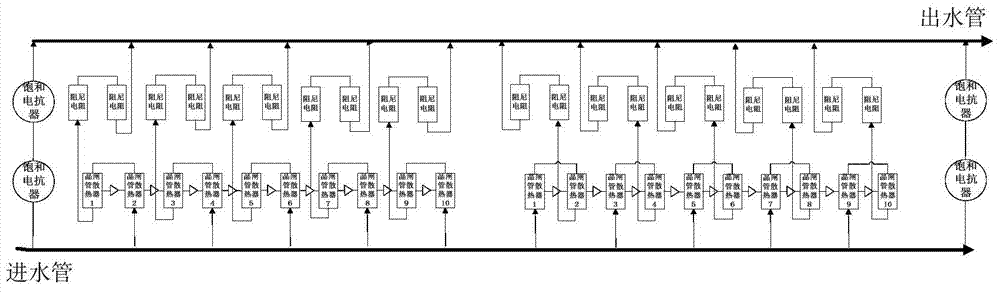

[0022] This embodiment takes the module flow equalization waterway for DC converter valves as an example, as shown in figure 1 As shown, the flow equalization water circuit of the DC converter valve module provided by the embodiment of the present invention includes: water inlet pipe, water outlet pipe, saturated reactor, thyristor radiator, damping resistor and water distribution connection pipe, and the cooling water circuit circuit adopts parallel series mixed The thyristor radiator, damping resistor branch and saturated reactor branch are composed of thyristor radiators arranged in the same type.

[0023] Among them, the water inlet pipe and the water outlet pipe are arranged in parallel, and the thyristor radiator and the damping resistor series branch connected in parallel are cooled by adopting a diagonal water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com