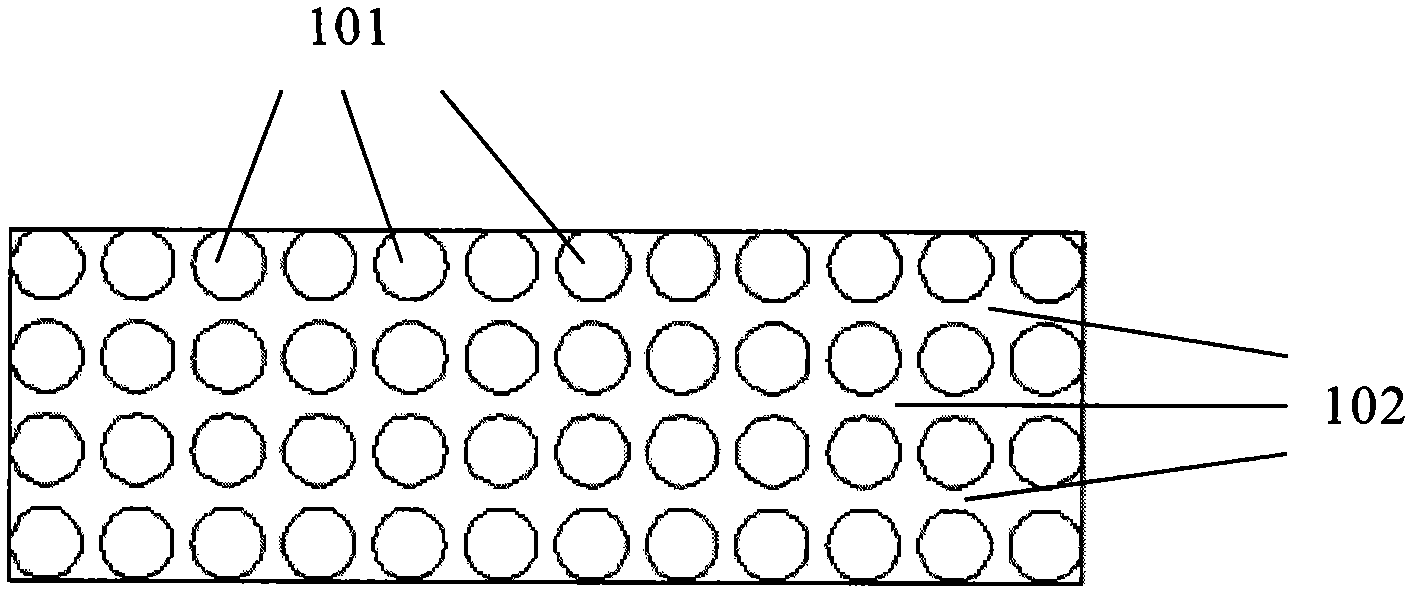

Component used for supporting photovoltaic solar module

A photovoltaic module and component technology, which is applied in the support structure of photovoltaic modules, photovoltaic modules, solar thermal energy, etc., can solve the problems of increasing the cost and complexity of photovoltaic modules, and low rigidity of elastomers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

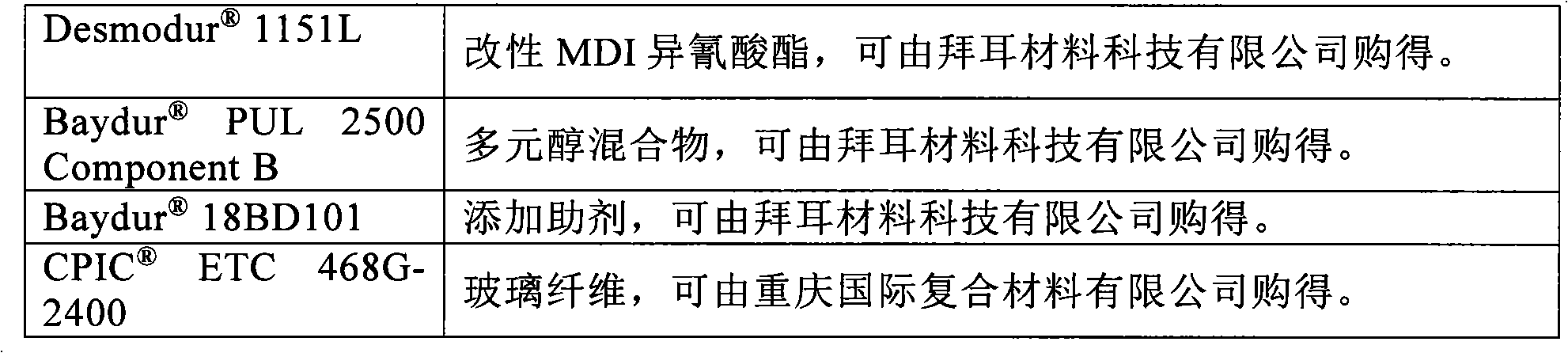

[0044] Raw Materials and Reagents

[0045]

[0046] The fiber passes through the yarn guide plate, resin infiltration box or injection box in turn, the fiber is fully infiltrated in the resin infiltration box or injection box and the air bubbles are squeezed out, and then enters the shaping mold, with appropriate speed and temperature settings, pull out profiles. After the profile leaves the mouth of the shaping die for a certain distance, it is completely cured in the resin curing zone. The pultrusion machine used is a 4-ton crawler pultrusion machine produced by Nanjing Nuoertai Composite Material Equipment Manufacturing Co., Ltd., and the metering and mixing equipment is an MVP MINI LINK machine provided by Magnum Venus Plastech in the United States.

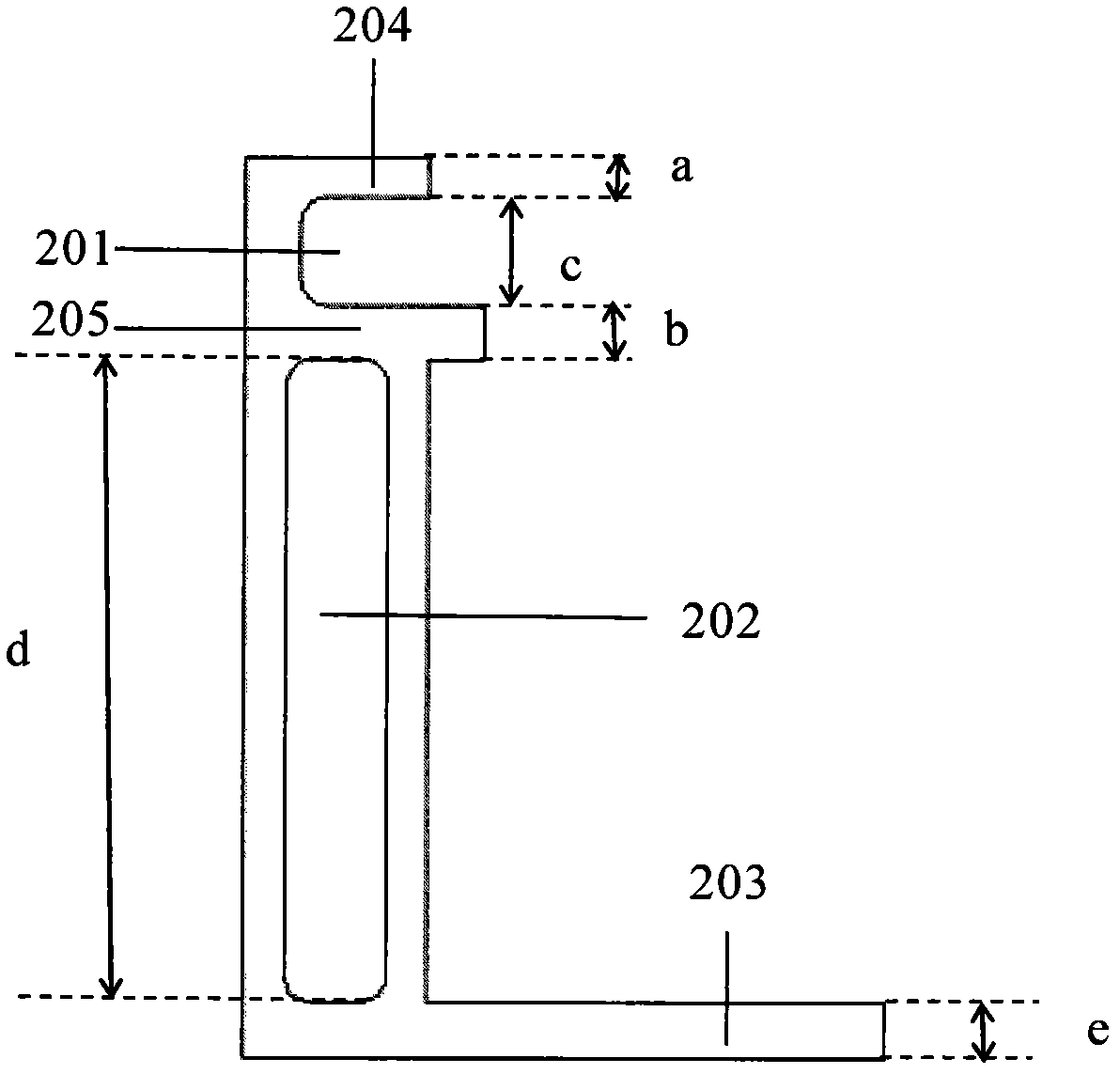

[0047] The flat-like profile produced by the above pultrusion process has a cross-section of 200mm x 3.2mm. This profile can be cut to the appropriate size and shape as required by the test method. The test results of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com