SiC single crystal and method for manufacturing same, SiC wafer, and semiconductor device

一种单晶、生长晶体的技术,应用在半导体器件、半导体/固态器件制造、晶体生长等方向,能够解决不能避免叠层缺陷、难以切出大直径的衬底、偏离角大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

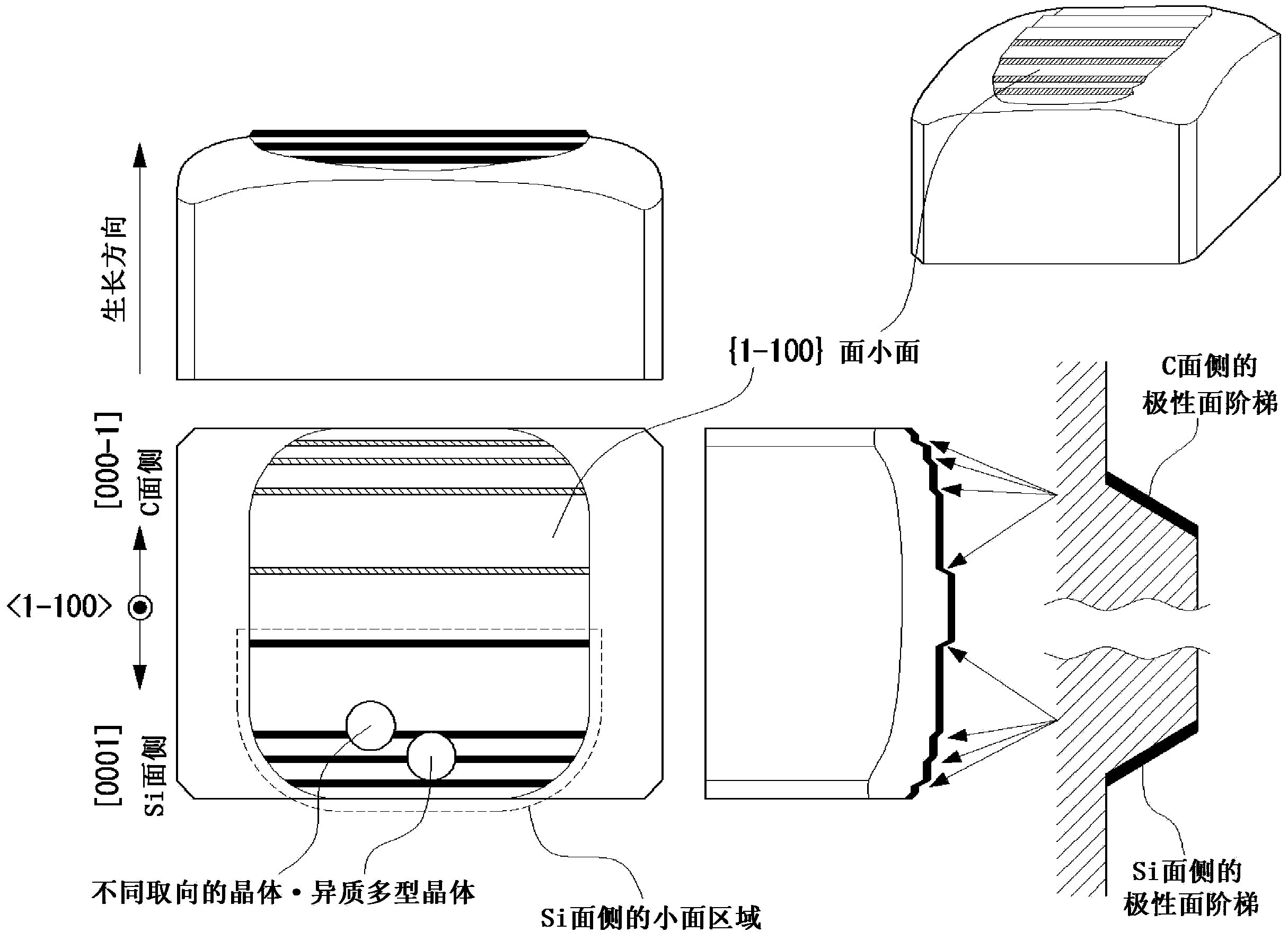

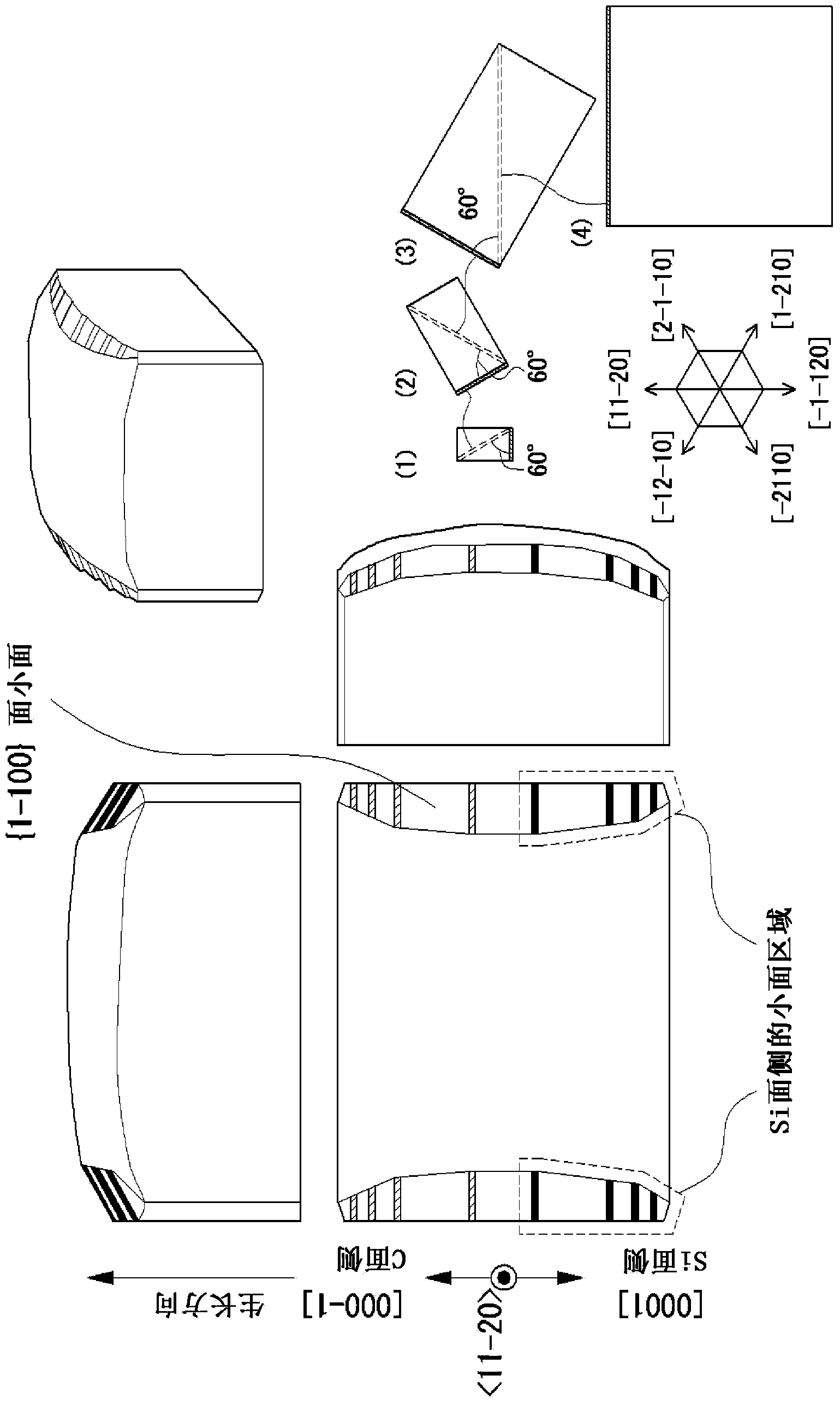

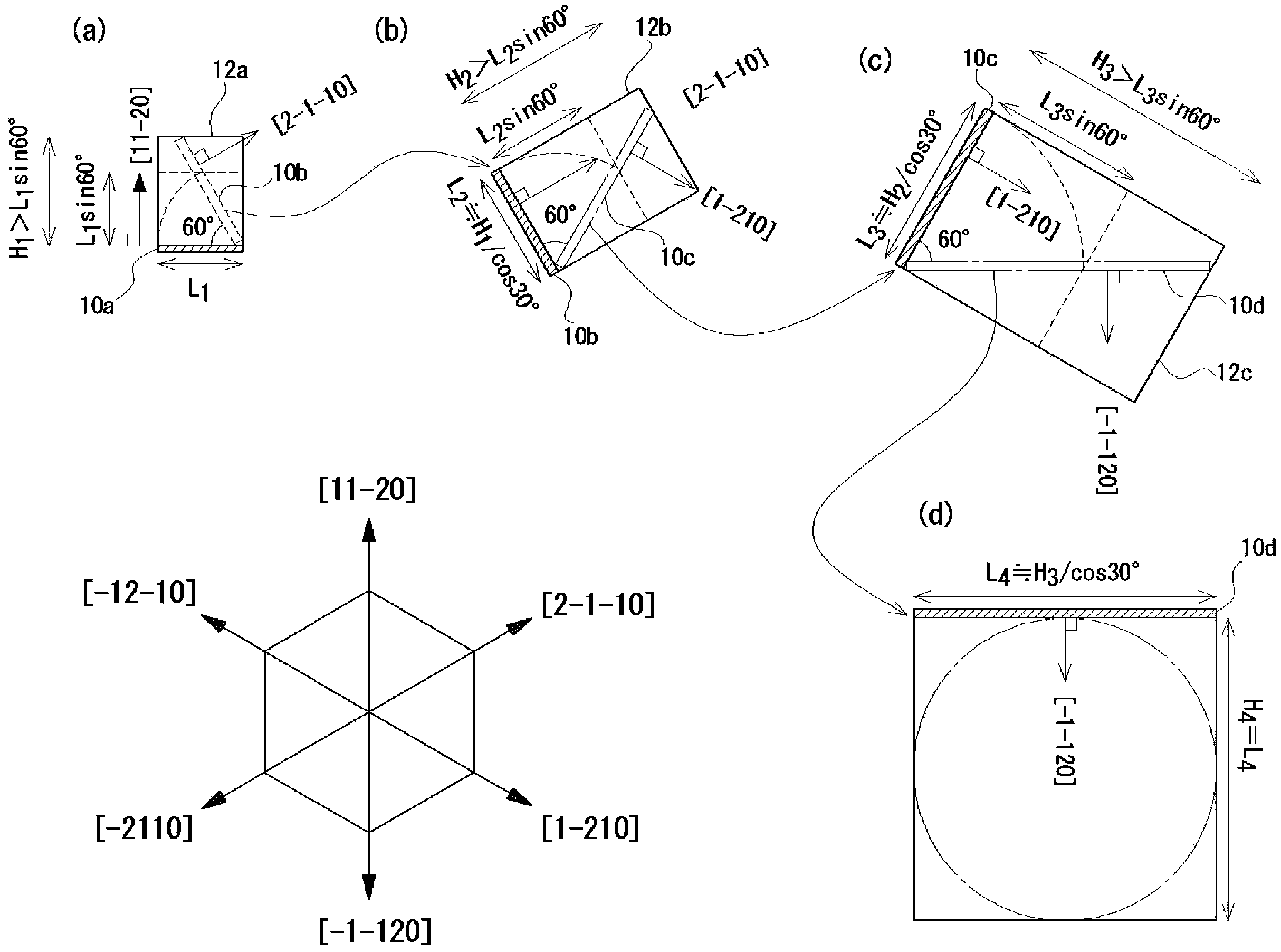

[0079] Hereinafter, preferred embodiments of the present invention will be described in detail.

[0080] [1. Definition of terms]

[0081] [1.1.a surface growth]

[0082] The term "growth plane" means a plane for growing a seed crystal of a new single crystal composed of SiC.

[0083] The term "a-plane growth" means growing a new single crystal composed of SiC by using a plane whose off angle from the {11-20} plane or {1-100} plane is within a predetermined range as a growth plane.

[0084] The term "{11-20} plane growth (or growth)" refers to growing a new single cell composed of SiC by using a plane whose off angle from the {11-20} plane is within a predetermined range as a growth plane. crystal.

[0085] The term "{1-100} plane growth (or growth)" refers to growing a new single cell made of SiC by using a plane whose off angle from the {1-100} plane is within a predetermined range as a growth plane. crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com