Special feed for laying hens in winter

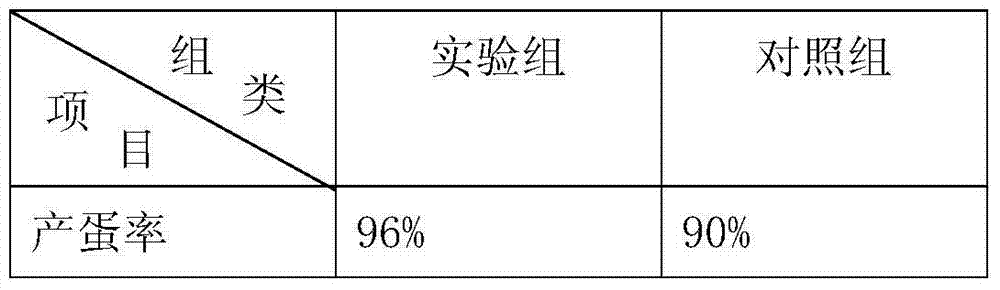

A feed and laying hen technology, applied in the field of livestock and poultry feed, can solve the problems of reducing concentrated feed, feed waste, increasing breeding costs, etc., and achieve the effects of good food intake, egg production rate, and content increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] The chicken feed of this embodiment is made from the following raw materials in parts by weight: 100 parts of rice bran, 40 parts of rye bran, 150 parts of corn, 45 parts of wheat straw, 35 parts of sweet potato seedlings, 20 parts of white radish sprouts, and 8 parts of potato skins. 10 parts of peanut powder, 15 parts of sweet potato leaves, 2 parts of pork bone powder, 2 parts of calcium hydrogen phosphate, 1 part of chicken feather powder, 1 part of black fungus powder, 3 parts of black sesame powder, 1 part of palm oil, 5 parts of wild chrysanthemum , an appropriate amount of salt, 4 parts of food attractant, food attractant is composed of the following raw materials in parts by weight: salted duck egg yolk 5, barley oil 2, laver 4, white fungus 2, green tea 2, wheat germ 2, peach leaf 4, mature vinegar 2, 3 betel leaves, 2 bellworts, 2 arbuscular Polygonum, 35 flour, appropriate amount of water; the preparation method is to mix other ingredients except salted duck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com