Method for improving peel strength of sandwich beam by aid of rare earth

A technology of peel strength and sandwich beam, applied in the field of aluminum-based alloys, can solve the problems of absurdity, asymmetry, and inability to realize the bond strength of sandwich beams, and achieve the effect of simple, easy and practical method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

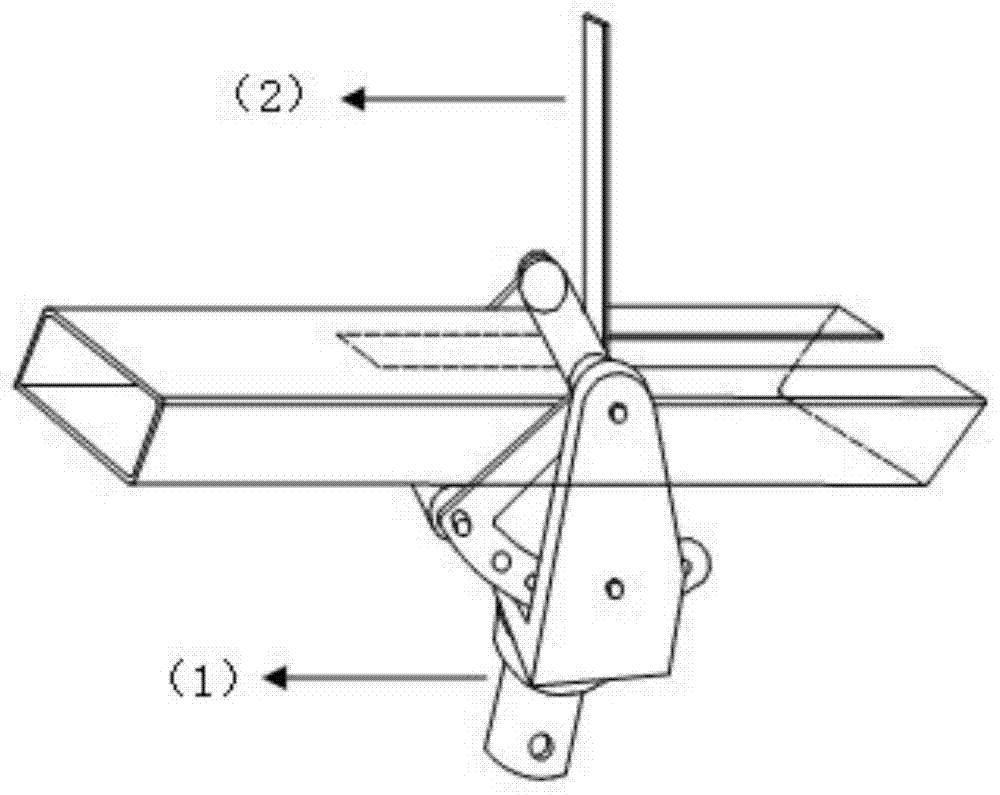

[0051] The steps and methods of the method for using rare earths to improve the peel strength of sandwich beams are as follows:

[0052] The first step is to determine the raw material of the sandwich beam:

[0053] (1) The rigid skin is selected from industrial Q235 thin-walled rectangular square steel. The wall thickness of the square steel is 1mm, and the profile size is 25mmX50mmX4000mm.

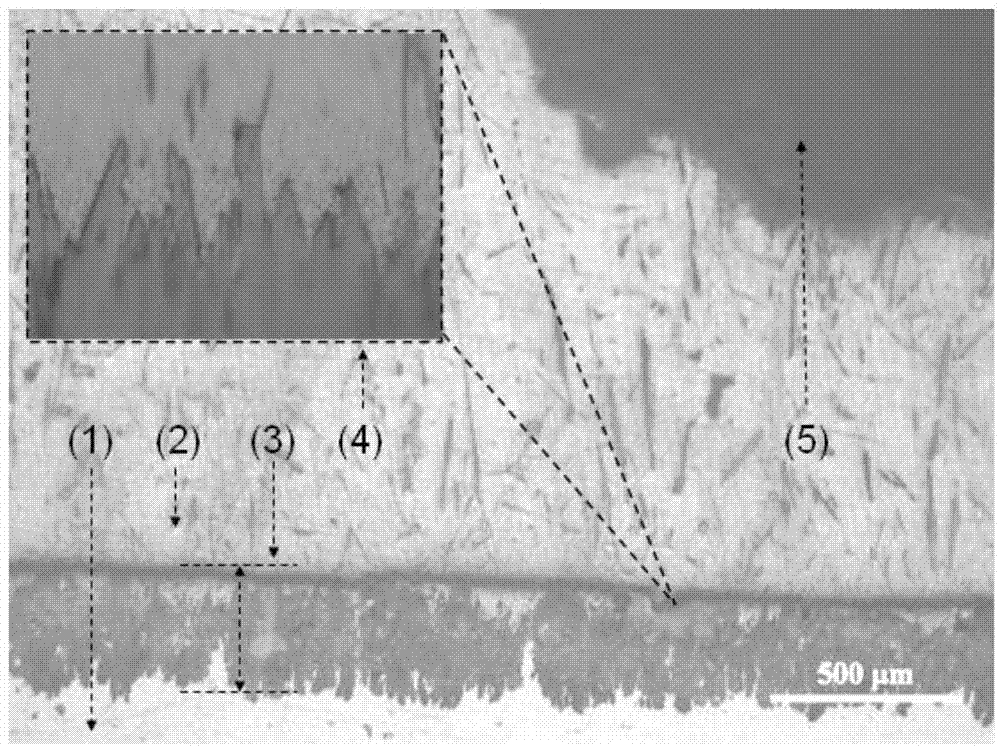

[0054] (2) The aluminum material used in the porous metal inner core is a low-silicon aluminum alloy block. The chemical composition of the low-silicon aluminum alloy block is: 99.6wt.% of aluminum metal, 0.2wt.% of silicon, and 0.05wt.% of magnesium metal. %, metal iron is 0.1wt.%, metal manganese is 0.02wt.%, metal zinc is 0.02wt.%, and other unavoidable metal impurities are 0.01wt.%.

[0055] (3) The rare earth used in the low-silicon aluminum alloy block is lanthanum-cerium mixed rare earth metal, and the single rare earth composition of the mixed rare earth metal is: 35wt.% of meta...

Embodiment 2

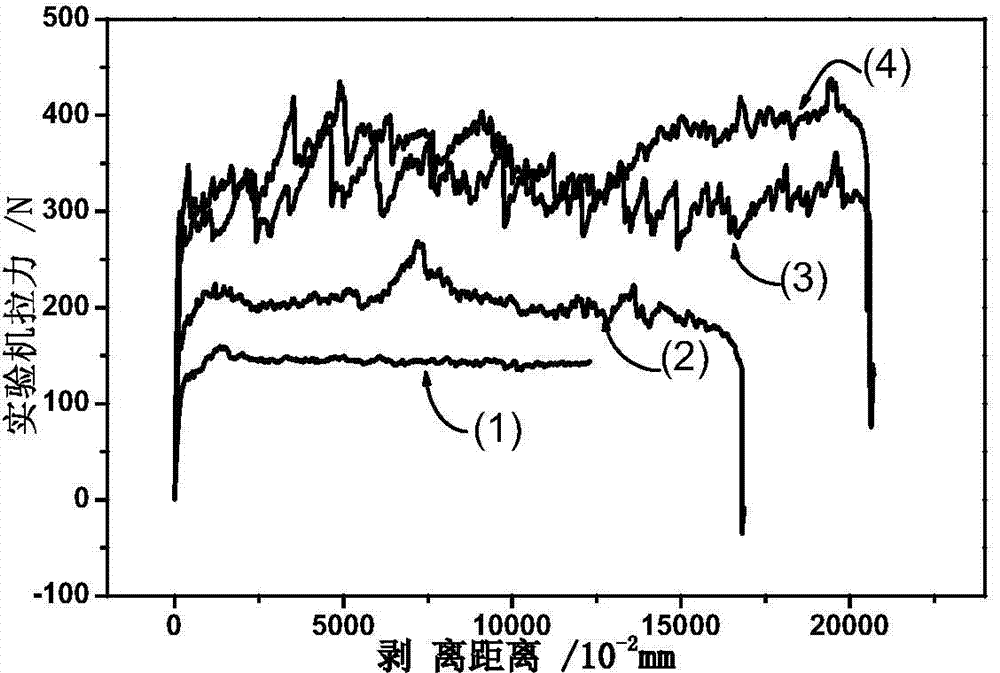

[0072] The steps and methods adopted are the same as in Example 1. The difference from Example 1 is that when one of the two variable conditions described in Example 1 is "the time interval between the end of stirring and the beginning of casting is controlled within 2 minutes", the condition is used "The time interval between the end of stirring and the start of casting is controlled within 4 minutes" replaced. After the kinetic time of the rare earth activity is doubled, the average peel strength and maximum peel strength of the obtained sandwich beams are both reduced, and the specific values are: σ 90(平均) =3.95kN / m; σ 90(MAX) = 5.16 kN / m.

[0073] All the other are with embodiment 1.

Embodiment 3

[0075]The steps and methods adopted are the same as those in Example 1. The difference from Example 1 is that when one of the two variable conditions described in Example 1 is "the amount of rare earth added to the aluminum alloy is 1wt.%" is replaced by " The amount of rare earth added to the aluminum alloy is 0.5wt.%" replacement. The average peel strength and maximum peel strength of the sandwich beam obtained by this replacement all increase compared with Example 1, and its specific value is: σ 90(平均) =5.03kN / m; σ 90(MAX) =5.64kN / m.

[0076] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com