A controllable degradable anti-adhesive film and its preparation method

A technology of anti-adhesive film and anti-adhesive layer, applied in the field of controllable degradable anti-adhesive film and its preparation, to reduce the risk of water leakage, reduce pollution, and ensure the effect of normal use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

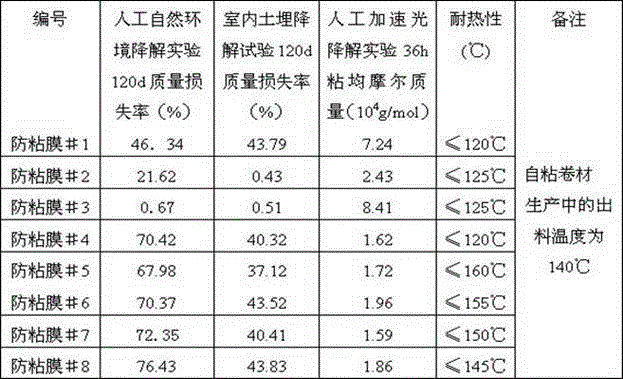

Image

Examples

Embodiment 1

[0086] The controllable degradable anti-adhesive film 1# is prepared by the above preparation method with the following raw material ratio:

[0087] Anti-adhesive layer: 100.0 parts of high-density polyethylene,

[0088] Middle layer: linear low density polyethylene 50.0 parts

[0089] 30 parts of modified starch masterbatch

[0090] Composite photodegradant 0 parts

[0091] 6 parts of 800-1200 mesh heavy calcium carbonate powder

[0092] Masterbatch (black) 4.0 parts

[0093] 10.0 copies of trimmed recycled materials

[0094] Bottom layer: HDPE 80.0 parts

[0095] Linear low density polyethylene 15.0 parts

[0096] Masterbatch (white) 5.0 parts

[0097] Anti-sticking agent: 12.0 parts of vinyl silicone oil,

[0098] 3.5 parts of chloroplatinic acid

[0099] 1.3 parts of hydrogen-containing silicone resin,

[0100] 0.7 parts of styrene-butadiene resin

Embodiment 2

[0103] The controllable degradable anti-adhesive film 2# is prepared by the above preparation method by taking the following raw material ratio:

[0104] Anti-adhesive layer: high-density polyethylene 100.0 parts

[0105] Middle layer: linear low density polyethylene 59.2 parts

[0106] Modified starch masterbatch 0 parts

[0107] Composite photodegradant 0.8 parts

[0108] Masterbatch (black) 5.0 parts

[0109] 15 parts of 800-1200 mesh quartz powder

[0110] 20.0 copies of trimmed recycled materials

[0111] Bottom layer: HDPE 90.0 parts

[0112] Linear low density polyethylene 5.0 parts

[0113] Masterbatch (white) 5.0 parts

[0114] Anti-sticking agent: vinyl silicone oil 18.0 parts,

[0115] 7.5 parts of chloroplatinic acid

[0116] Hydrogen-containing silicone resin 2.0 parts,

[0117] 1.2 parts of styrene-butadiene resin

Embodiment 3

[0120] The controllable degradable anti-adhesive film 5# is prepared by the above preparation method by taking the following raw material ratio:

[0121] Anti-adhesive layer: 100.0 parts of high-density polyethylene,

[0122] Middle layer: 55 parts of linear low density polyethylene

[0123] Modified starch masterbatch 0 parts

[0124] Composite photodegradant 0 parts

[0125] Masterbatch (black) 5.0 parts

[0126] 20 parts of 800-1200 mesh heavy calcium carbonate powder

[0127] 20.0 copies of trimmed recycled materials

[0128] Bottom layer: HDPE 70.0 parts

[0129] Linear low density polyethylene 24.0 parts

[0130] Masterbatch (white) 6.0 parts

[0131] Anti-sticking agent: 20.0 parts of vinyl silicone oil,

[0132] 3.5 parts of chloroplatinic acid

[0133] 1.3 parts of hydrogen-containing silicone resin,

[0134] 0.7 parts of styrene-butadiene resin

[0135] 74.5 parts of 120# solvent gasoline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com