Work-starting method of apparatus for producing low carbon alkene from methanol

A technology of low-carbon olefins and methanol, which is applied in the field of start-up of methanol-to-low-carbon olefins units, and achieves the effect of fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

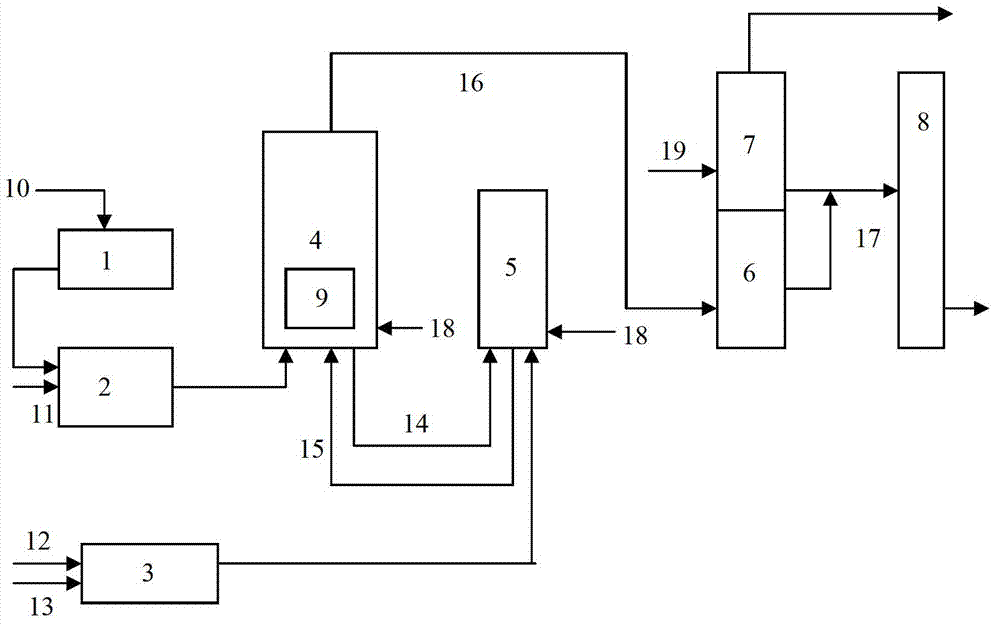

Method used

Image

Examples

Embodiment 1

[0138] The hot nitrogen from the heating furnace and the hot air from the auxiliary combustion chamber heat the reactor to 400°C and the regenerator to 550°C respectively according to a certain temperature rise curve. The heating rate is 15°C / h. After the temperature rise of the two vessels is completed, the regenerator starts to add catalyst, and then the reactor is filled with catalyst, and the total amount of catalyst is finally added to the required amount through the fluidization of the two vessels. The catalysts in the two vessels are heated to 370°C and 420°C respectively. Crude methanol with a water content of 4.5% passes through the methanol vaporizer and enters the start-up heating furnace to be preheated to 300°C and enters the reactor. At this time, adjust the operation. When the reactor temperature is higher than 400°C, the fluidization of the reactor and the regenerator will start and gradually stabilize. operate. The product gas generated by the reactor enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com