Butadiene preparation method

A technology of butadiene and cyclohexene, which is applied in the field of butadiene preparation, can solve the problems of low yield of butadiene and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The method for preparing butadiene according to the present invention comprises subjecting cracking raw materials to steam cracking reaction, the cracking raw materials contain cyclohexene, and the content of cyclohexene in the cracking raw materials is 5-100% by weight.

[0015] In order to further increase the yield of butadiene, the content of cyclohexene in the cracking raw material is preferably 10-100% by weight, more preferably 20-100% by weight, and even more preferably 50-100% by weight.

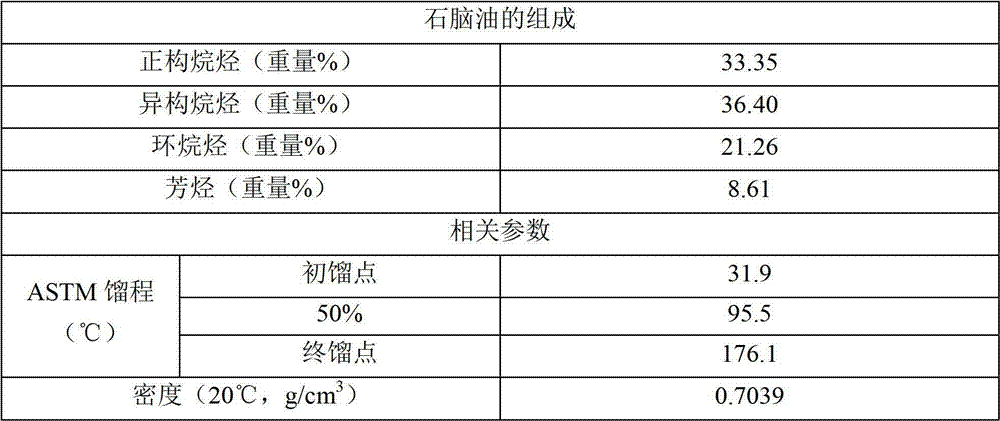

[0016] In the present invention, the steam cracking reaction can be carried out in a cracking furnace. Among the cracking raw materials, in addition to cyclohexene, the cracking raw materials may also contain cracking raw materials commonly used in this field, such as light hydrocarbons, naphtha, diesel oil, hydrogenated tail oil, and the like. However, since cyclohexene is used in combination with naphtha, a relatively high yield of butadiene can be obtained, and coking in t...

Embodiment 1-4 and comparative example 1

[0027] The cracking raw materials were respectively injected into the CBL-III cracking furnace (purchased from China Petrochemical Corporation) for steam cracking reaction, and the yield of butadiene was detected. Among them, the cracking raw materials and reaction conditions are shown in Table 2 below. The cracking raw materials The mixing ratios in are weight ratios. The cracked gas (ie steam cracking reaction product) was collected, its composition was analyzed, and the yield of butadiene was calculated. The results are shown in Table 2 below.

[0028] Table 2

[0029]

[0030] It can be seen from the data in Table 2 that the butadiene production method according to the present invention can obtain a significantly improved butadiene yield. Specifically, by comparing Example 1 with Comparative Example 1, it can be seen that the cracking raw material used in Comparative Example 1 is naphtha, and the cracking raw material used in Example 1 is cyclohexene, and as a result, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com