Novel febuxostat crystal form A and preparation method thereof

A technology of febuxostat and crystal form, which is applied in the field of pharmaceutical chemical crystallization, can solve problems such as difficulty in realizing industrial production, unstable preparation process, harsh conditions, etc., and achieve industrialized large-scale production, solvent recovery and application, and reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

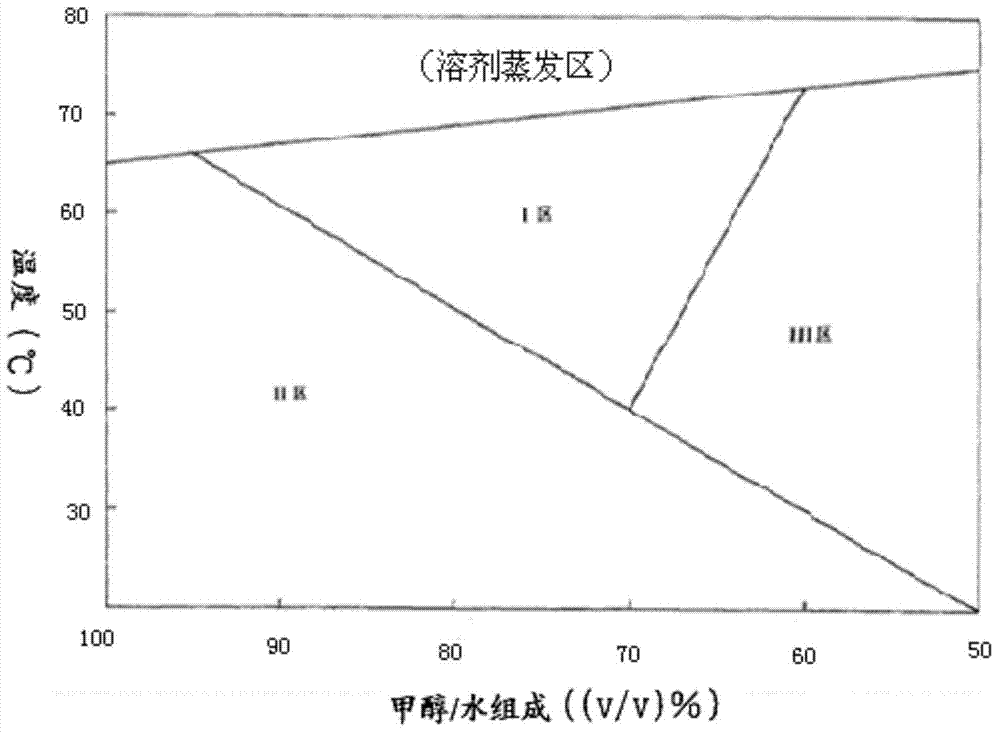

Method used

Image

Examples

Embodiment 1

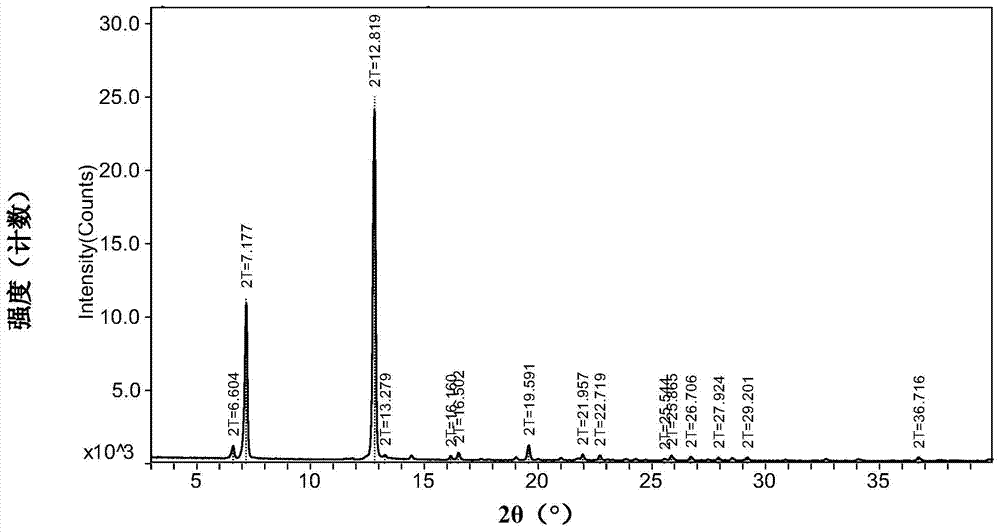

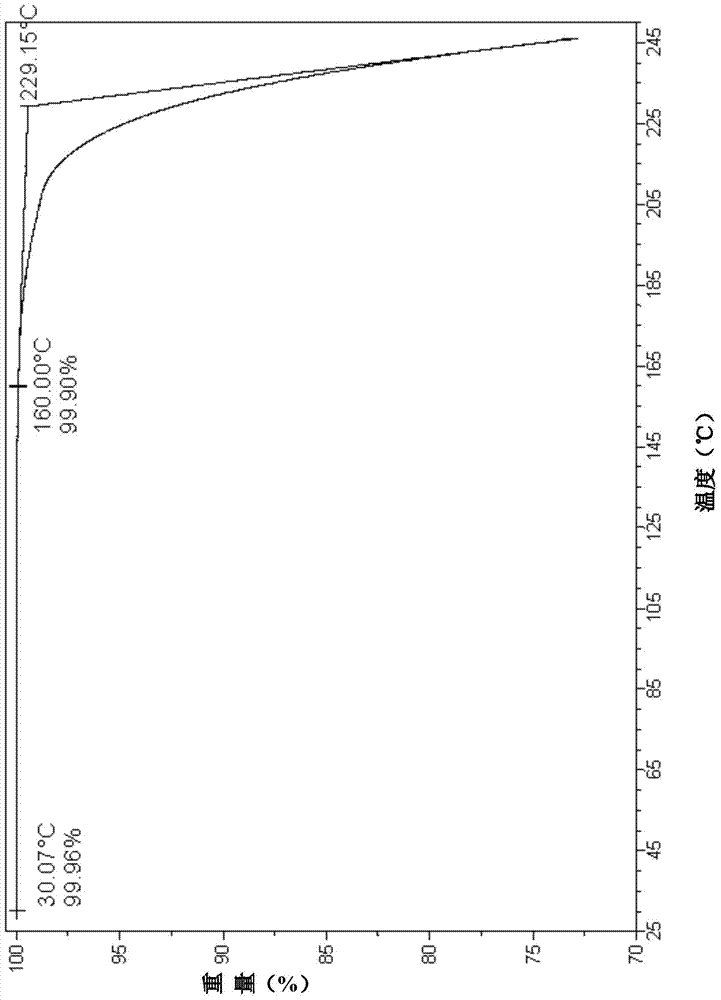

[0066] Add 100mL of isopropanol to the jacketed reaction flask containing 3g of febuxostat sample, stir at a stirring rate of 300r / min, heat up to 70°C, the system dissolves, keep at this temperature for 10min, and cool down to Add 0.06g of seed crystals with a median particle size of 5μm at 62°C, and then use the equal-time segmental cooling method to lower the temperature from 62°C to 15°C within 1 hour, and first drop the temperature from 62°C to 52°C within 20 minutes , followed by a temperature drop from 52°C to 37°C within 20 minutes, and finally a temperature drop from 37°C to 15°C within 20 minutes, and suction filtration. The wet sample was air-dried at 40°C for more than 6 hours and weighed to obtain a white powder solid with a yield of 95.0%. After checking the X-ray powder diffraction pattern of this white powder solid, see figure 1 , is a single febuxostat crystal form A, its particle size distribution diagram is shown in Figure 5 , its D 50 is 23.8μm, and it...

Embodiment 2

[0068] Add 200mL of isopropanol to the jacketed reaction flask containing 30g of febuxostat sample, stir at a stirring rate of 900r / min, heat up to 75°C, the system dissolves, keep at this temperature for 10min, and cool down to Add 0.09g of seed crystals with a median particle size of 10μm at 62°C, and then use an equal-time segmental cooling method to reduce the temperature from 62°C to 15°C within 2 hours, and first drop the temperature from 62°C to 52°C within 40 minutes. Next, the temperature dropped from 52°C to 37°C within 40 minutes, and finally from 37°C to 15°C within 40 minutes, and suction filtered. The wet sample was air-dried at 60°C for more than 6 hours and weighed to obtain a white powder solid with a yield of 95.2%. After checking the X-ray powder diffraction pattern of this white powder solid and figure 1 Consistent, it is a single febuxostat crystal form A, and its particle size distribution is the same as Figure 5 similar, its D 50 It is 25.0 μm, and ...

Embodiment 3

[0070] Add 83.3L of isopropanol to the jacketed reaction flask containing 10kg of febuxostat sample, stir at a stirring rate of 600r / min, heat up to 75°C, the system dissolves and becomes light yellow-green, at this temperature Keep the temperature for 10 minutes, cool down to 62°C and add 0.1kg of seed crystals with a median particle size of 10μm, and then use the equal-time segmental cooling method to lower the temperature from 62°C to 15°C within 8 hours, firstly within 160 minutes. The temperature dropped to 52°C, then the temperature dropped from 52°C to 37°C in 160 minutes, and finally the temperature dropped from 37°C to 15°C in 160 minutes, and suction filtered. The wet sample was air-dried at 50°C for more than 6 hours and weighed to obtain a white powder solid with a yield of 96.7%. After checking the X-ray powder diffraction pattern of this white powder solid and figure 1 Consistent, it is a single febuxostat crystal form A, and its particle size distribution is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com