Railroad sleeper

A technology for railway rails and sleepers, which is applied in the direction of tracks, roads, coatings, etc., can solve the problems that the mixed distribution of fiber reinforced materials and resins cannot be guaranteed, the application cannot be widely applied, and the quality of sleepers is affected, so as to achieve good economic benefits and insulation Good, low overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

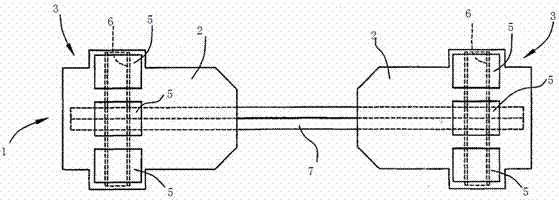

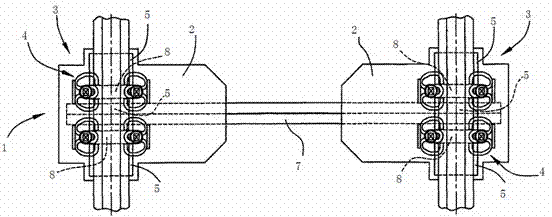

[0036] A railway sleeper comprising a sleeper body 1 with two blocks 2 each having a track bearing area 3 in which the sleeper body 1 is widened . The rails are secured in each rail bearing region 3 by means of pressure elements 4 engaging the rail base. Each rail bearing area 3 has three rail bearing surfaces 5 arranged side by side in the direction of rail extension, with gaps 8 provided between the rail bearing surfaces 5 . At least one pressing element 4 is arranged on each said rail bearing surface 5 or in the gap 8 in each rail bearing region 3 . At least one first stiffening element 6 arranged in the direction of extension of the track extends respectively within the sleeper body 1 below the track bearing area 3; at least one second stiffening element 7 passes through the sleeper body 1, The second stiffening elements 7 extend in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com