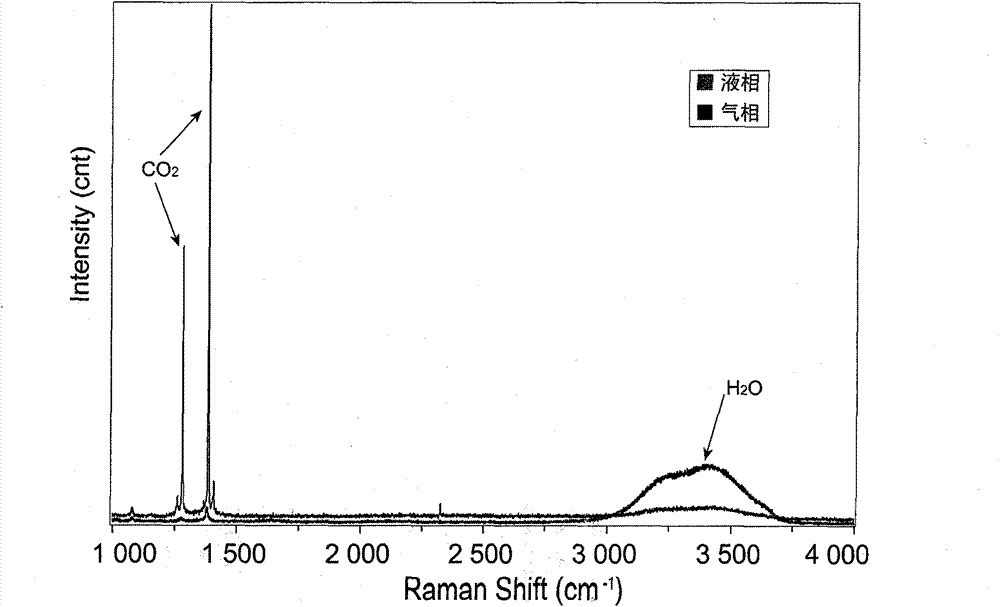

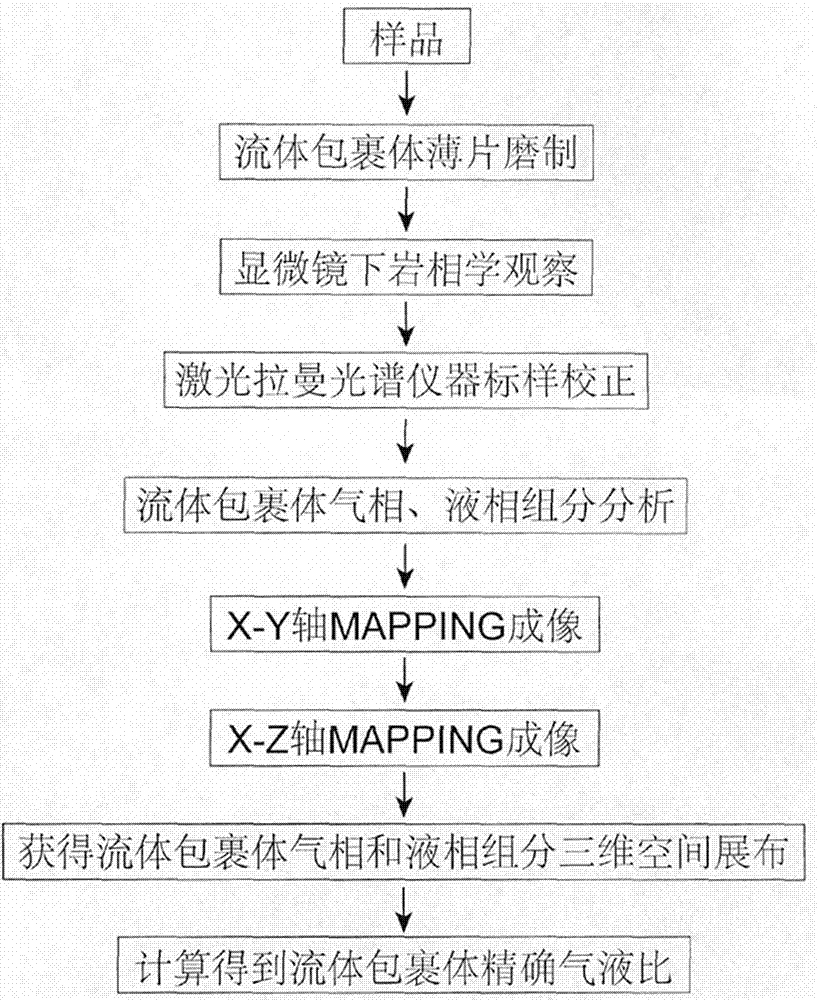

Method for determining vapor-liquid ratio of fluid inclusion based on laser Raman Mapping

A fluid inclusion and inclusion technology, applied in Raman scattering, material excitation analysis, etc., can solve the problem that the gas-liquid ratio cannot be accurately calculated, and achieve the effect of easy operation and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Taking a geological sample as an example below, the specific implementation method of the present invention will be further described in detail in conjunction with the accompanying drawings. The laser Raman spectrometer model used in this experiment is LabRAM Aramis (manufactured by HORIBA JobinYvon, France). Specific steps are as follows:

[0018] Step 1: Sample Preparation

[0019] The rock samples were sliced, polished thin slices on both sides, with a thickness of 0.1-0.3 mm, and conventional fluid inclusion thin slices were obtained.

[0020] Step 2: Observing fluid inclusions under a microscope

[0021] Observation and analysis of fluid inclusions under a microscope, including size, type, appearance, fluorescence characteristics, etc.

[0022] Step 3: Perform standard sample calibration on the instrument

[0023] First you need to use a silicon wafer (520.7cm -1 ) standard sample to calibrate the Raman spectrometer. When the standard sample is calibrated, sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com