Diamond / metal composite material clamping rod and manufacturing method thereof

A metal composite material and diamond technology, which is applied in the field of vacuum electronics, can solve the problems of easy brittle fracture, difficult manufacturing, and difficult assembly, and achieve the effects of not easy brittle fracture, high bonding strength, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

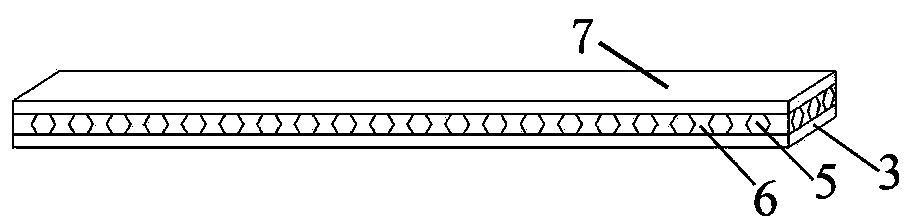

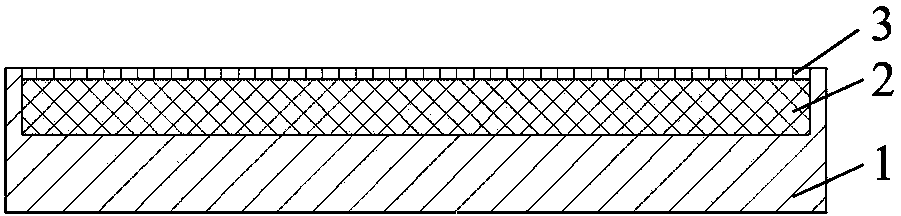

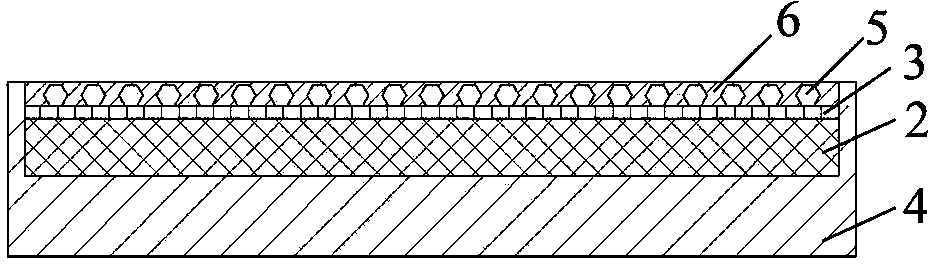

[0042] Such as figure 1 A diamond / metal composite clamping rod shown includes three layers, the upper and lower layers are a first layer of CVD diamond film 3 and a second layer of CVD diamond film 7, the middle is a metal layer 6, and the metal layer 6 It is a metal layer coated with artificial diamond particles of similar particle size and consistent crystal orientation, wherein the diamond particles of the metal layer are connected to the upper and lower layers of CVD diamond films.

[0043] The shape of the clamping rod is a long rod with a rectangular cross-section, 52mm long, 0.7mm high, and 0.2mm wide; the artificial diamond particles are mainly diamond particles produced by high temperature and high pressure method, and the crystal orientation is preferably (100). The thickness is 0.4-0.5mm; the metal layer element is a strong carbide metal element that can form a good bonding strength with diamond, which can be Ti, W, Mo, Cr, Nb, Zr, Ta, Hf, etc.; The thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com