VCM thin film for solar light concentration and application thereof and solar photovoltaic cell

A technology of solar energy concentration and thin film, which is applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of difficult preparation, high processing cost, and bulky structure, and achieve broad application prospects, low manufacturing cost, and high reflection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

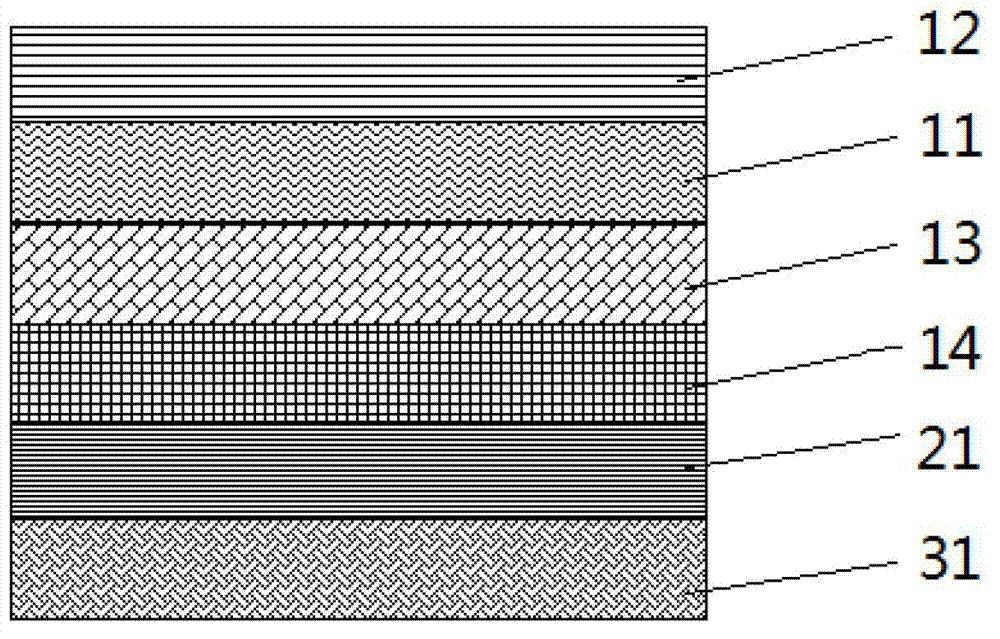

[0030] figure 1 It is a schematic structural view of the solar concentrating VCM film of Example 1. The VCM film for solar energy concentrating sequentially includes: a hard-coating (Hard-coating) 12, a transparent film layer 11, a light transmittance enhancing coating 13, a vacuum metallization coating 14, an adhesive layer 21 and a base film layer 31 .

[0031] Raw materials used in the preparation method of the solar concentrating VCM film:

[0032] The transparent film of the transparent film layer is a BOPET film with a thickness of 23 microns, and the light transmittance of the original film is over 90%. ] requirements.

[0033] The surface hardening coating is selected from Kangnam Chemical co., Ltd., product name: UV coating, model: UV (KUV-001) polyurethane surface hardening coating, which is fully stirred evenly before use.

[0034] The paint for the enhanced light transmittance coating is purchased from Tangcai Film Technology Co., Ltd., Shunde District, Foshan ...

Embodiment 2

[0044] same with figure 1 As an example, Embodiment 2 will be described. The VCM film for solar energy concentrating sequentially includes: a hard-coating (Hard-coating) 12, a transparent film layer 11, a light transmittance enhancing coating 13, a vacuum metallization coating 14, an adhesive layer 21 and a base film layer 31 .

[0045] Raw materials used in the preparation method of the solar concentrating VCM film:

[0046] The transparent film of the transparent film layer is a BOPET film with a thickness of 12 microns, and the light transmittance of the original film is over 90%. ] requirements.

[0047] The surface hardening coating is selected from Kangnam Chemical co., Ltd., product name: UV coating, model: UV (KUV-001) polyurethane surface hardening coating, which is fully stirred evenly before use.

[0048] The paint for the enhanced light transmittance coating is purchased from Tangcai Film Technology Co., Ltd., Shunde District, Foshan City. The product name: hig...

Embodiment 3

[0058] same with figure 1 Embodiment 2 will be described as an example. The VCM film for solar energy concentrating sequentially includes: a hard-coating (Hard-coating) 12, a transparent film layer 11, a light transmittance enhancing coating 13, a vacuum metallization coating 14, an adhesive layer 21 and a base film layer 31 .

[0059]Raw materials used in the preparation method of the solar concentrating VCM film:

[0060] The transparent film of the transparent film layer is a high-permeability PVC film with a thickness of 50 microns. The haze of the original film is lower than 2.0%. and sheet] on request.

[0061] The surface hardening coating is selected from Kangnam Chemical co., Ltd., product name: UV coating, model: UV (KUV-001) polyurethane surface hardening coating, which is fully stirred evenly before use.

[0062] The paint for the enhanced light transmittance coating is purchased from Tangcai Film Technology Co., Ltd., Shunde District, Foshan City. The product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com