Line structure and manufacturing method thereof

A technology of circuit structure and production method, which is applied in the direction of multilayer circuit manufacturing, printed circuit components, and electrical connection formation of printed components, can solve problems such as signal line interference and affect signal transmission integrity, and reduce electromagnetic wave interference. The effect of signal transmission quality and reduction of crosstalk noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

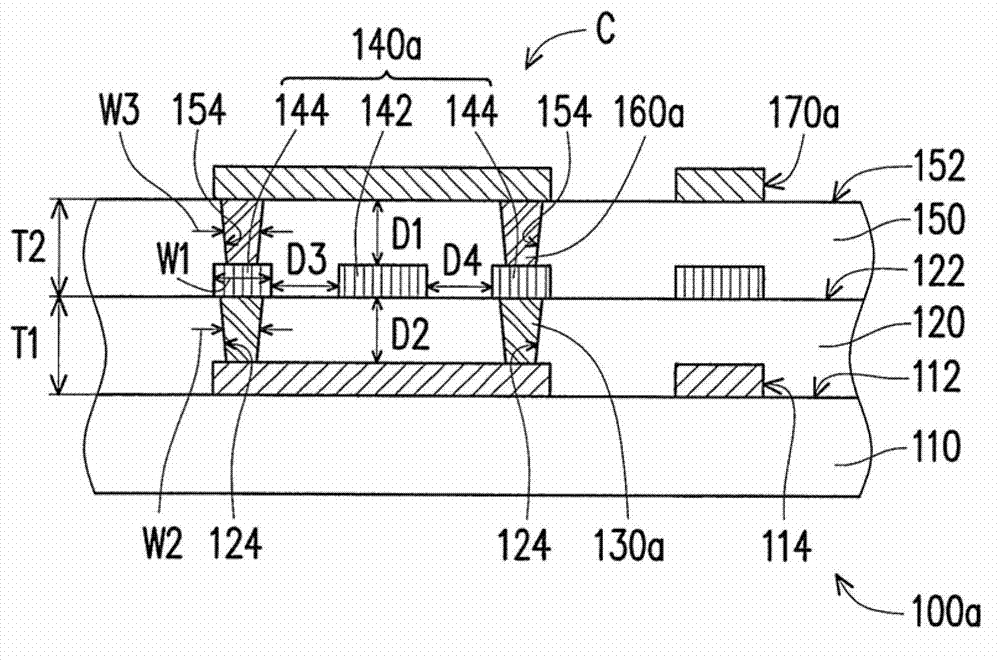

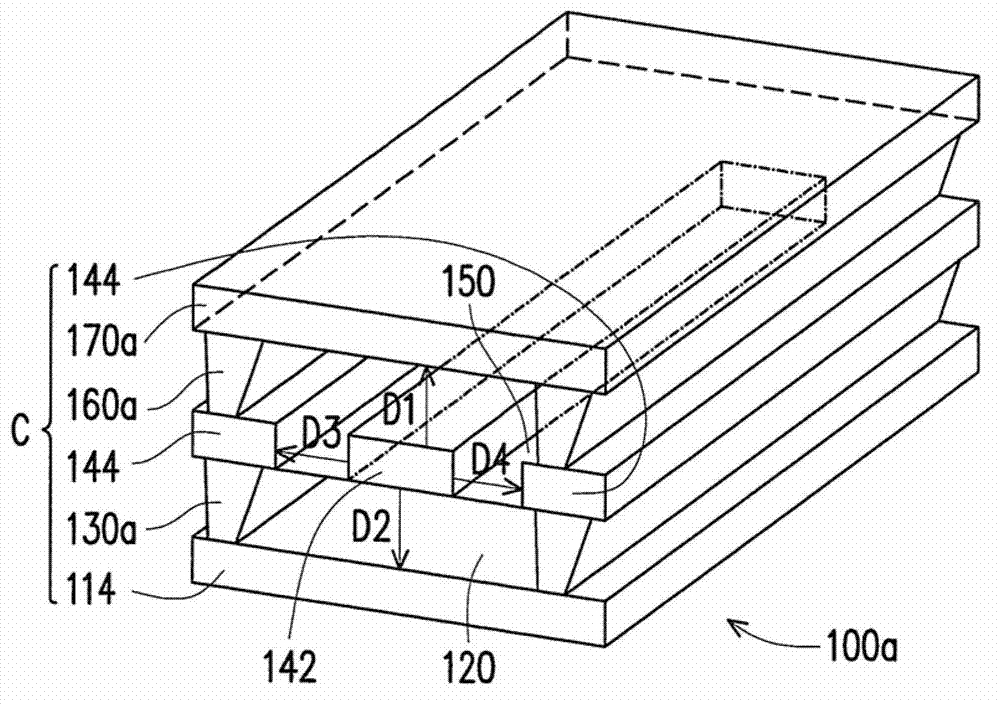

[0048]Figure 1A It is a schematic cross-sectional view of a circuit structure according to an embodiment of the present invention. Figure 1B for Figure 1A A partial three-dimensional schematic diagram of the line structure. Please also refer to Figure 1A and Figure 1B , in this embodiment, the wiring structure 100a includes an inner wiring layer 110, a first dielectric layer 120, a first conductive material layer 130a, a second conductive layer 140a, a second dielectric layer 150, a The second conductive material layer 160a and a third conductive layer 170a.

[0049] In detail, the inner circuit layer 110 has an upper surface 112 and a first conductive layer 114 disposed on the upper surface 112 . The first dielectric layer 120 is disposed on the inner circuit layer 110 and covers the upper surface 112 and the first conductive layer 114 . The first dielectric layer 120 has a first surface 122 and a plurality of first circuit trenches 124 extending from the first surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com