Method for synthesizing NaA zeolite membrane with high membrane forming efficiency

A zeolite membrane and membrane-forming technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing the separation performance of synthetic membranes, unable to completely eliminate pore defects on the carrier surface, and achieve high membrane-forming rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

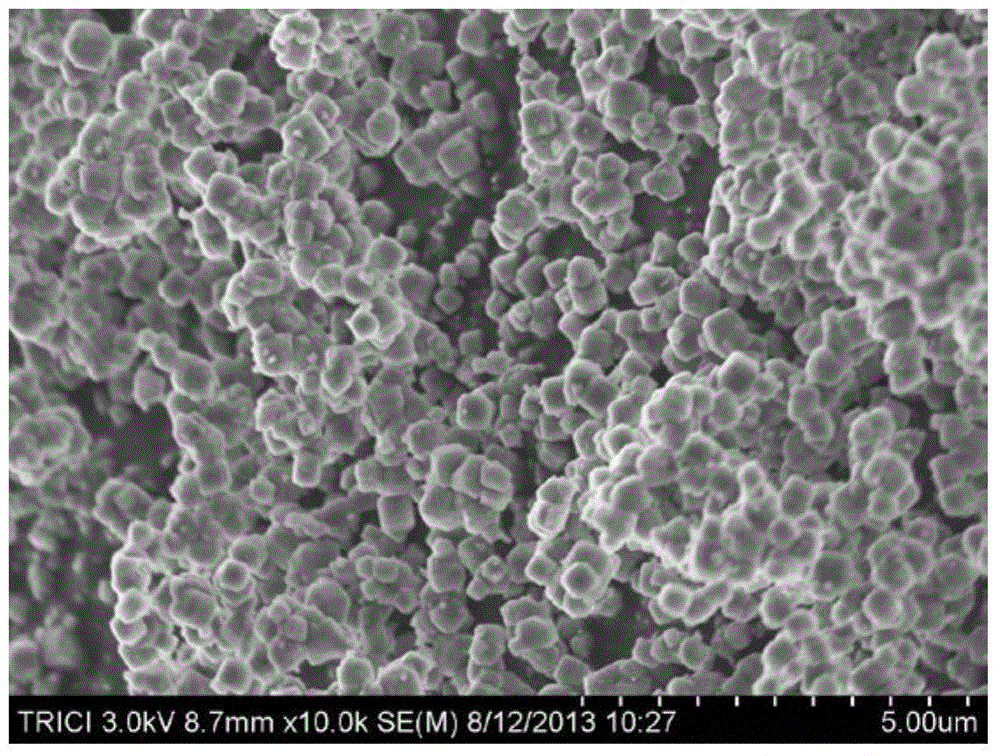

[0037] The invention discloses a method for preparing NaA zeolite membrane by vacuum suction filtration seed crystal method. Its preparation steps are as follows:

[0038] 1. Take α-Al 2 o 3 The outer surface of the carrier tube was polished smooth with 1200# sandpaper, and then the polished α-Al 2 o 3 The carrier tube was immersed in 0.1mol / L hydrochloric acid solution and 0.1mol / L sodium hydroxide solution successively, ultrasonically oscillated for 0.5h respectively, washed with deionized water until neutral after taking it out, dried in an oven at 50°C for 16h, and then placed in a horse Calcined in Furnace at 200°C for 2h, took it out for use.

[0039] 2. Select NaA molecular sieve seed crystals and deionized water to prepare a 0.1 g / L seed crystal aqueous solution, and use ultrasonic dispersion to disperse the obtained solution for 2 hours, and then let it stand for 12 hours. stand-by.

[0040] 3. Seal both ends of the carrier tube with polytetrafluoroethylene. He...

Embodiment 2

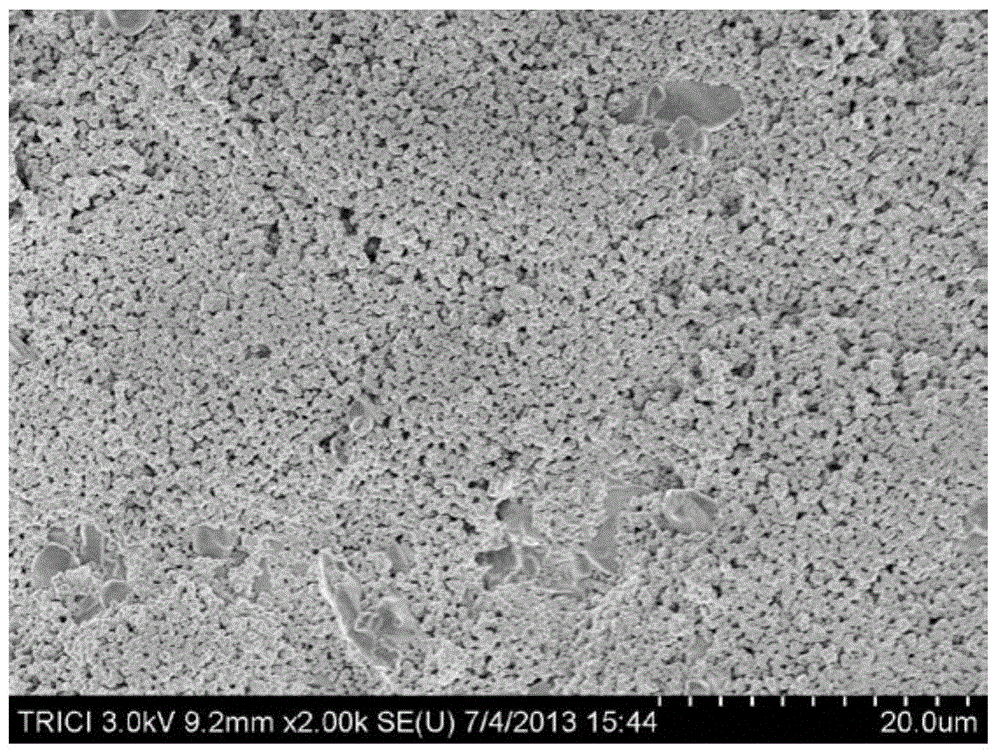

[0045] The invention discloses a method for preparing NaA zeolite membrane by vacuum suction filtration seed crystal method. Its preparation steps are as follows:

[0046] 1. Take α-Al 2 o 3 The outer surface of the carrier tube was polished smooth with 1200# sandpaper, and then the polished α-Al 2 o 3 The carrier tube was immersed in 0.8mol / L hydrochloric acid solution and 0.8mol / L sodium hydroxide solution successively, ultrasonically oscillated for 1 hour respectively, washed with deionized water until neutral after taking it out, dried in an oven at 80°C for 20 hours, and then placed in a muffle Calcined in the furnace at 280°C for 3h, then took it out for use.

[0047] 2. Select NaA molecular sieve seed crystals and deionized water to prepare a 0.5g / L seed crystal aqueous solution, and use ultrasonic dispersion to disperse the obtained solution for 4 hours, and then let it stand for 18 hours. stand-by.

[0048] 3. Seal both ends of the carrier tube with polytetraflu...

Embodiment approach 3

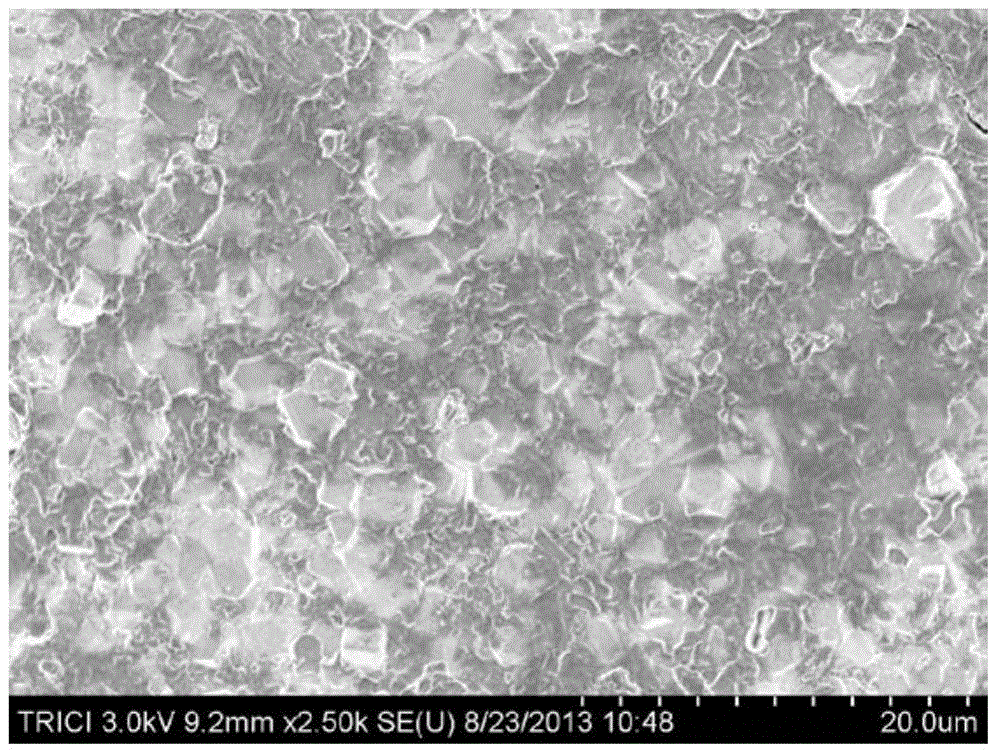

[0053] The invention discloses a method for preparing NaA zeolite membrane by vacuum suction filtration seed crystal method. Its preparation steps are as follows:

[0054] 1. Take α-Al 2 o 3 The outer surface of the carrier tube was polished smooth with 1200# sandpaper, and then the polished α-Al 2 o 3 The carrier tube was soaked in 0.8mol / L hydrochloric acid solution and 0.8mol / L sodium hydroxide solution successively, ultrasonically oscillated for 1 hour respectively, washed with deionized water until neutral after being taken out, dried in an oven at 90°C for 24 hours, and then placed in a muffle Calcined in the furnace at 350°C for 4h, then took it out for use.

[0055] 2. Select NaA molecular sieve seed crystals and deionized water to prepare a 0.8g / L seed crystal aqueous solution, and use ultrasonic dispersion to disperse the obtained solution for 5 hours, and then let it stand for 20 hours. stand-by.

[0056] 3. Seal both ends of the carrier tube with polytetraflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com