Method for welding carbon steel and stainless steel composite plates

A welding method and composite plate technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as mixing, increase effective thickness, ensure corrosion resistance, and eliminate metal mixing and gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

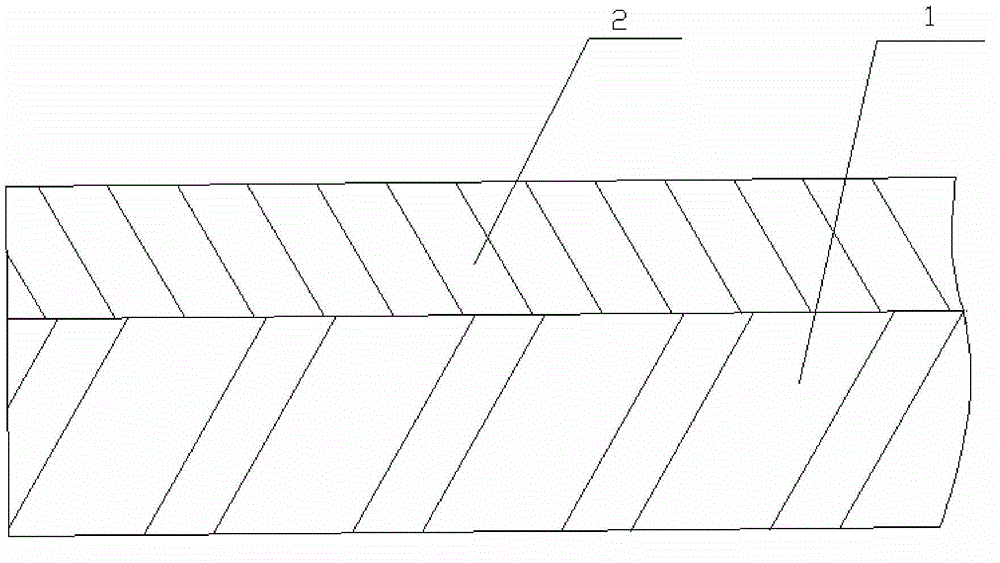

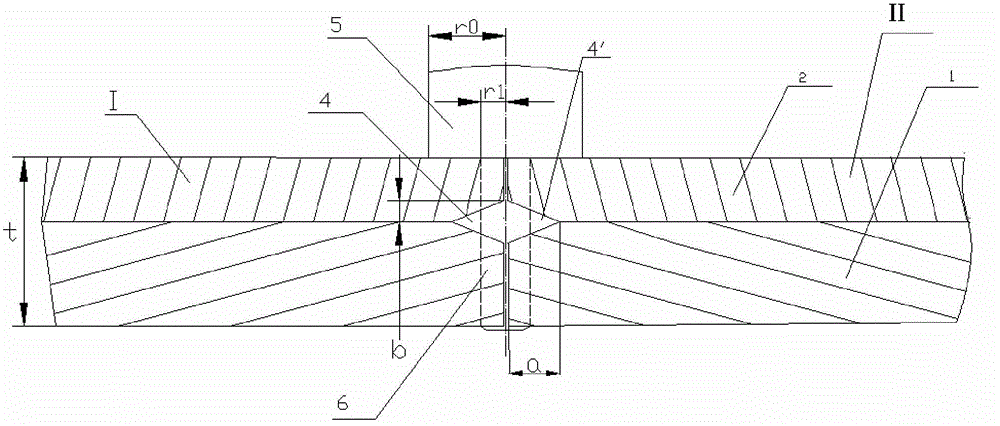

[0022] Such as figure 1 As shown, taking the rolled composite plate as an example, the base plate 1 is carbon steel with a thickness of 20mm, the clad plate 2 is stainless steel with a thickness of 10mm, and the thickness of the composite plate is t=30mm. The butt welding steps are:

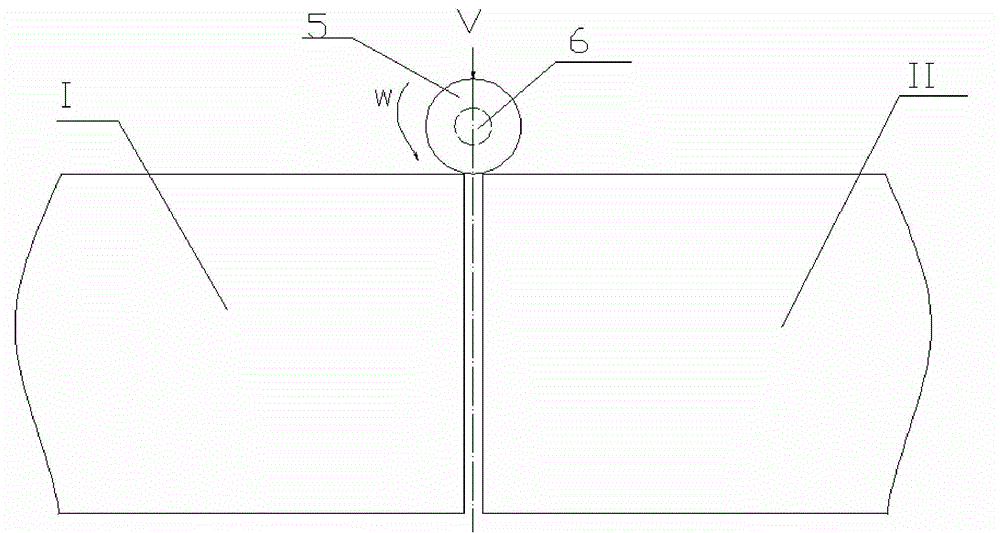

[0023] 1. If figure 2 As shown, take the composite plates I and II of A and B, and machine the left and right bevels 4 and 4' in the shape of isosceles triangles at the ends of their butt welding edges. The left and right bevels have the same shape and size, and the bottom The sides are opposite, the lateral height a=kl=kπωμFr 1 / 90000V, where ω=600r / min, μ=0.3, F=10KN, r 1 =15mm, V=60mm / min, k is 1.05 according to field operation experience. Calculated a=16.5mm, b=3mm determined by field operation experience. After the processing is completed, clean the rust on the groove.

[0024] 2. Align the butt edges of A and B composite plates I and II with the grooves, and fill the 309 stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com