Method for grouting construction of prestressed pipe

A technology of prestressed pipes and construction methods, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as hidden dangers of bridge safety, uncompact grouting of prestressed holes, common quality problems, etc., so as to improve the safety life and shorten the construction. Construction period and the effect of ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

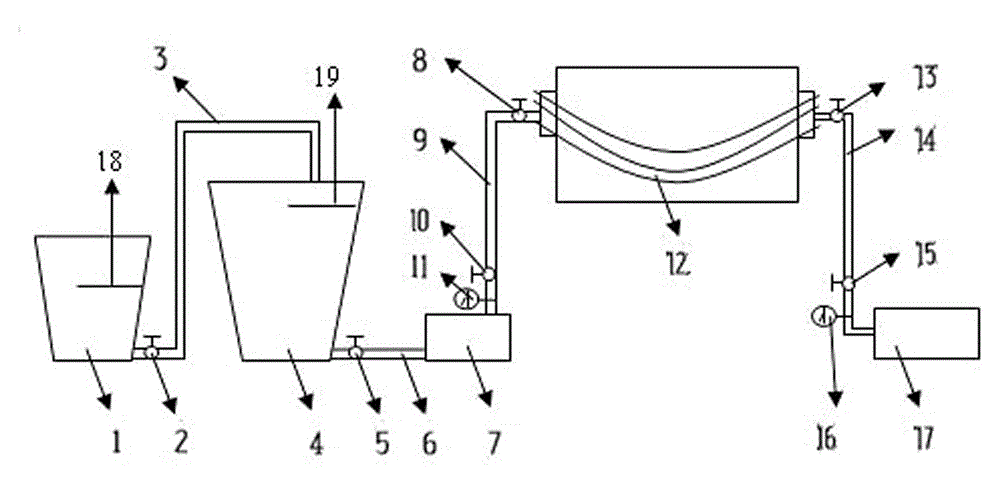

[0024] A prestressed pipeline grouting construction method, comprising the following process steps:

[0025] 1. Selected equipment, including pulping machine 1, slurry storage tank 4, pulping machine 7 and vacuum pump 17.

[0026] The pulping machine 1 is connected with the slurry storage tank 4 through the first rubber pipe 3 , and the first valve 2 is installed on the first rubber pipe 3 . The discharge port at the lower end of the slurry storage tank 4 is connected to the feed port of the grout press 7 through a second rubber tube 6 , and a second valve 5 is installed on the second rubber tube 6 . The discharge port of the grouting machine 7 is connected with the feed port of the prestressed pipeline 12 with steel strands through the third rubber tube 9 , and the third rubber tube 9 is equipped with a third valve 8 and a fourth valve 10 . The other end of the prestressed pipeline 12 with steel strands is connected to a vacuum pump 17 through a transparent hose 14, and a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com