Device and method for detecting slow release performance of concrete slump retaining agent

A slow-release performance and slump-retaining agent technology, which is applied in the field of building materials, can solve problems such as cognitive barriers and guidance errors, and there is no relevant standard for slump-retaining agents, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

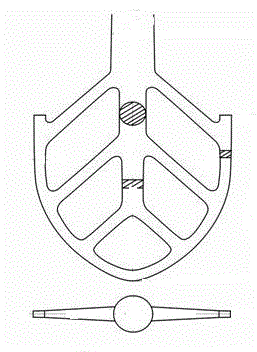

[0023] Put the mixer in the standby state first, and then operate according to the following procedures: Add 175g of water and 1.6% slump-retaining agent (concentration: 10%) into the pot, then add 300g of cement and 150g of fly ash, put the pot Put it on the fixed frame, raise it to a fixed position, then start the machine immediately, after stirring at low speed for 30s, add sand evenly at the beginning of the second 30s, turn the machine to high speed and mix for another 30s. Stop stirring for 60s, use a spatula to scrape the plastic sand on the blade and pot wall into the middle of the pot within the first 15s, continue stirring at high speed for 60s, the error of stirring time at each stage should be within ±1s.

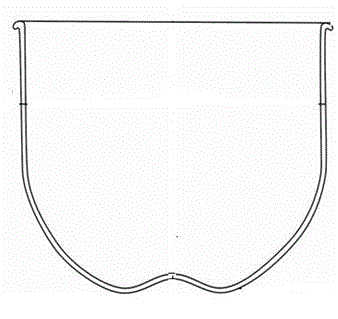

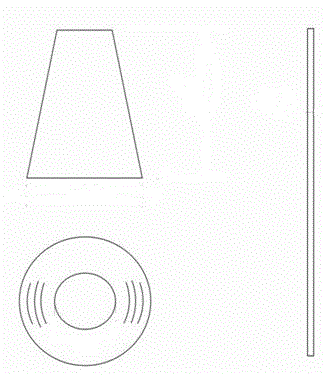

[0024] While mixing the slurry, wipe the glass plate, tamper, and truncated cone mold on the horizontal table with a damp cloth, place them in the center of the glass plate, and cover with a damp cloth for later use.

[0025] Put the mixed slurry into the mold t...

Embodiment 2

[0029] Put the mixer in the waiting state first, and then operate according to the following procedures: Add 182g of water and 1.6% slump-retaining agent (concentration: 10%) into the pot, then add 300g of cement, 100g of fly ash, ore Powder 50g, put the pot on the fixed frame, rise to a fixed position, then start the machine immediately, stir at low speed for 30s, add sand evenly at the beginning of the second 30s, turn the machine to high speed and mix for 30s. Stop stirring for 60s, use a spatula to scrape the plastic sand on the blade and pot wall into the middle of the pot within the first 15s, continue stirring at high speed for 60s, the error of stirring time at each stage should be within ±1s.

[0030] While mixing the slurry, wipe the glass plate, tamper, and truncated cone mold on the horizontal table with a damp cloth, place them in the center of the glass plate, and cover with a damp cloth for later use.

[0031] Quickly divide the mixed slurry into the mold in two...

Embodiment 3

[0035] Put the mixer in the standby state first, and then operate according to the following procedures: Add a certain amount of water and a set amount of slump-retaining agent into the pot, then add 300g of cement, 80g of fly ash, 50g of mineral powder, and 20g of mud powder , put the pot on the fixed frame, raise it to a fixed position, then start the machine immediately, after stirring at low speed for 30s, add sand evenly at the beginning of the second 30s, turn the machine to high speed and stir for another 30s. Stop stirring for 60s, use a spatula to scrape the plastic sand on the blade and pot wall into the middle of the pot within the first 15s, continue stirring at high speed for 60s, the error of stirring time at each stage should be within ±1s.

[0036]While mixing the slurry, wipe the glass plate, tamper, and truncated cone mold on the horizontal table with a damp cloth, place them in the center of the glass plate, and cover with a damp cloth for later use.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com