Method for analyzing content of scorch retarder CTP (N-cyclohexylthiophthalimide) in vulcanized rubber

A technology of vulcanized rubber and analysis method, which is applied in the field of rubber industry, can solve problems such as the blank of quantitative analysis method, and achieve the effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 vulcanized rubber sample preparation

[0031] The basic formula is (parts by mass):

[0032] Component 1: Natural Rubber NR30, Butadiene Rubber BR70; Carbon Black N37580, Process Oil 4.0, Stearic Acid 2.0, Zinc Oxide 2.0:;

[0033] Component 2: tackifying resin SL1801 4.0, antioxidant 4020 1.6, antioxidant RD1.5:;

[0034] Component 3: sulfur 1.0, vulcanization accelerator NS2.2, anti-scorch agent CTP (change the amount, add 0.1 to sample I; add 0.3 to sample II; add 1.0 to sample III).

[0035] Preparation process: In a 1.6-liter Banbury internal mixer (manufactured by FARREL), add component 1, gradually raise the temperature to 160°C and mix for 6 minutes to obtain a section of mixed rubber, which is left at room temperature for 16 hours; then continue to banbury internal mixing In the machine, mix the mixed rubber and component 2 at 145°C for 5 minutes to obtain the masterbatch, and cool the masterbatch to below 90°C; then use the XK-160 open rubber mi...

Embodiment 2

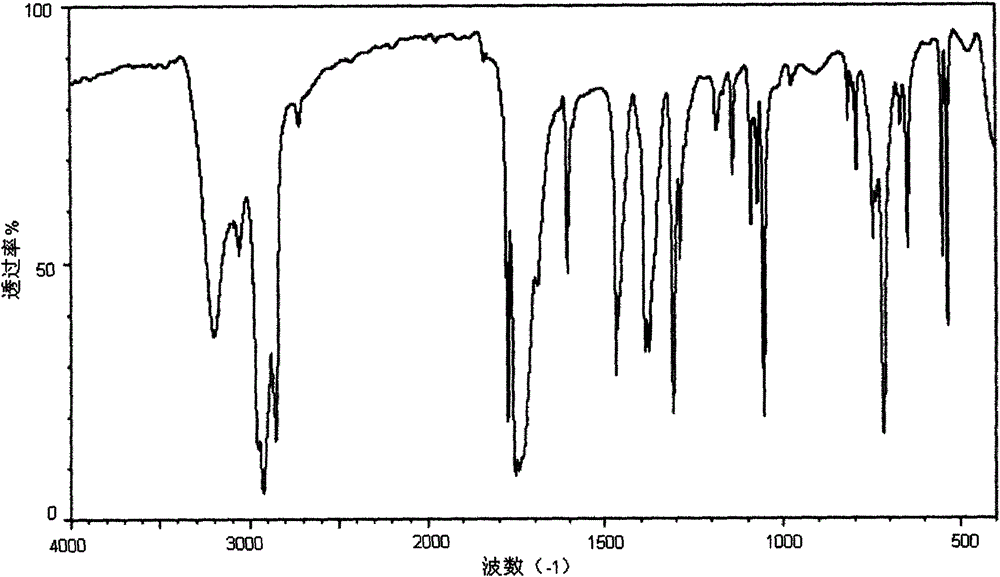

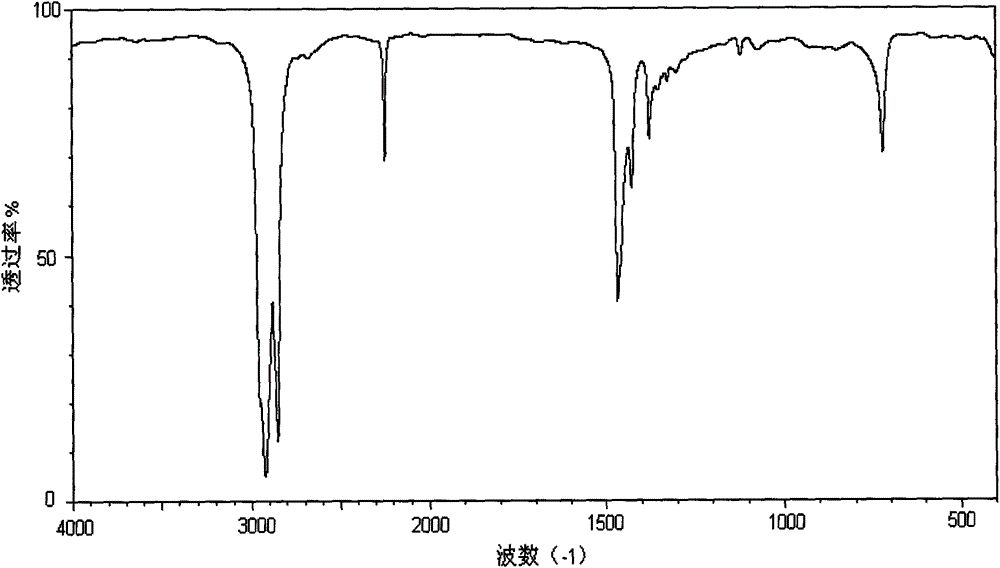

[0036] Embodiment 2: the consumption analysis of retarder in vulcanized rubber sample 1

[0037] 2.1, Preparation of standard series solutions: Weigh 100.081mg of phthalimide into a 50ml volumetric flask, dilute to volume with chloroform, prepare mother liquor A, weigh 616.8mg of dodecyl nitrile into a 100ml volumetric flask, and use Chloroform was fixed to volume, and mother liquor B was prepared. Quantitatively take 3ml of mother solution B with a pipette and transfer them into six 10ml volumetric flasks in sequence, then quantitatively take 250ul, 450ul, 900ul, 1400ul, 1850ul, and 2300ul of mother solution A with a pipette and transfer them into the above six 10ml volumetric flasks in sequence Finally, six 10ml volumetric flasks were distilled to volume with chloroform to obtain six standard series solutions containing internal standards (standard 1, standard 2, standard 3, standard 4, standard 5, and standard 6). The mass ratios of dicarboximide to internal standard dodec...

Embodiment 3

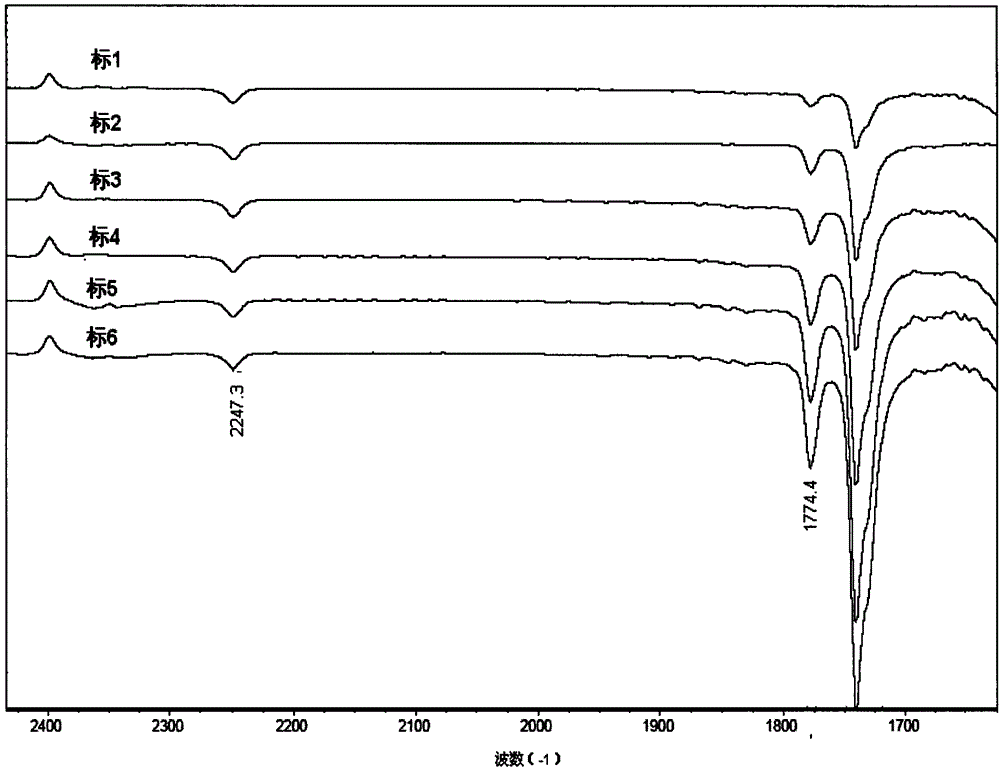

[0051] Example 3: Analysis of the amount of anti-scorch agent CTP in the laboratory self-made vulcanizate sample II

[0052] 3.1, Preparation of standard series solutions: Weigh 100.081mg of phthalimide into a 50ml volumetric flask, dilute to volume with chloroform, prepare mother liquor A, weigh 616.8mg of dodecyl nitrile into a 100ml volumetric flask, and use Chloroform was fixed to volume, and mother liquor B was prepared. Quantitatively take 3ml of mother solution B with a pipette and transfer them into six 10ml volumetric flasks in turn, and then quantitatively take 250ul, 450ul, 900ul, 1400ul, 1850ul, 2300ul of mother solution A with a pipette and transfer them into the above six 10ml volumetric flasks in sequence Finally, six 10ml volumetric flasks were distilled to volume with chloroform to obtain six standard series solutions (mark 1, mark 2, mark 3, mark 4, mark 5, mark 6). The mass ratios of amine to internal standard dodecylnitrile were 0.027, 0.049, 0.097, 0.151,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com