Fabric analysis system and method based on biaxial mechanical stretch processing

An analysis system, biaxial technology, applied in the direction of material analysis, material analysis, and scientific instruments through optical means, can solve problems such as unsatisfactory results, blurred structure texture, disordered image features, etc., to achieve The effect of solving the difficulty of automatic image recognition, clear organization, and easy measurement and recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

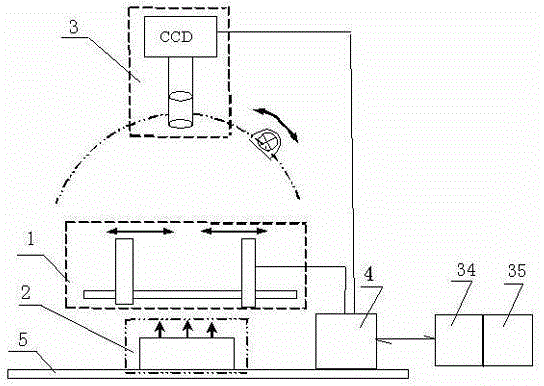

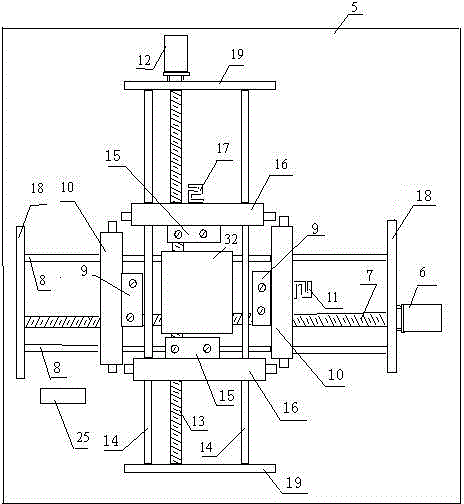

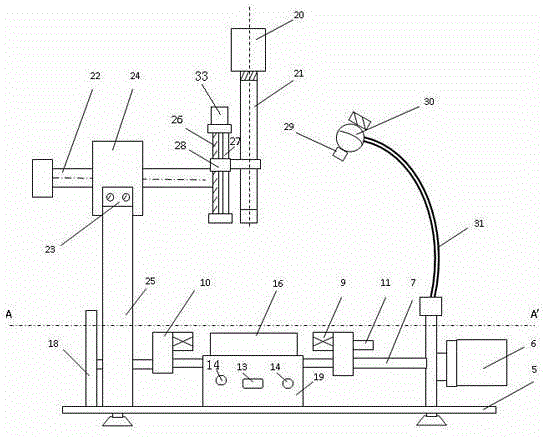

[0050] Embodiment 1: see Figure 1-Figure 10 , the present invention is a fabric analysis system for biaxial mechanical stretching treatment , It includes: an illumination device 2 , an optical observation and imaging system 3 , a signal acquisition control system 4 , a computer 34 and a fabric image analysis module 35 . A biaxial mechanical stretching device 1 is also configured to carry out biaxial mechanical stretching of the fabric sample along the warp and weft directions of the fabric to unfold the fabric, especially to unfold the tight fabric and the fabric that is squeezed, rubbed, twisted, and curled. , to make its organizational structure clear; the illuminating device 2 provides illumination to the unfolded fabric sample to enhance the different target features of the fabric image; The acquisition control system 4 is input to the computer 34; the signal acquisition control system 4 is used for fabric sample image and signal acquisition and control, and also control...

Embodiment 2

[0056] Embodiment 2: The present invention carries out the method for fabric analysis on the fabric analysis system of biaxial mechanical stretching treatment, stretches fabric by biaxial mechanical device 1, makes the warp and weft yarn in fabric straighten, slightly yarn gap, the fabric structure image is clear, and the combined lighting device provides different lighting effects for the fabric sample to enhance the identification features of useful information in the image. With the cooperation of the optical observation and imaging device, the computer controls the imaging three-dimensional adjustment mechanism to change the position of the lens. Positioning, focusing and image acquisition of fabric samples, and finally use the fabric image analysis software provided by the present invention to analyze the series of images collected to complete fabric texture analysis, colored yarn analysis and warp and weft yarn density measurement. The specific operation steps are as foll...

Embodiment 3

[0063] Embodiment 3: see Figure 9 , Figure 10 , carry out the test method of fabric biaxial nondestructive stretching on the fabric analysis system of biaxial mechanical stretching treatment of the present invention, test the force and force-displacement characteristic curve of fabric biaxial nondestructive stretching, Figure 9 The implementation steps of its testing process are shown:

[0064] ① Clamp the warp and weft directions of the square fabric sample cut to a certain size in two pairs of fabric sample holders in the X and Y directions;

[0065] ②Start the instrument, click the option "Connect" in the computer menu to connect the instrument to the computer, and the dialog box will display "Comm initialize OK!", indicating that the communication between the computer and the instrument is successful. "bit, indicating that the instrument initialization is complete;

[0066] ③Operation mode and control parameters, including: a. Select the working mode "stretch" or "re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com