Networked control method for rapid prototyping equipment

A technology of networked control and molding equipment, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the advanced problems of material, model and time arrangement, reduce the probability of error, prolong the service life, reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

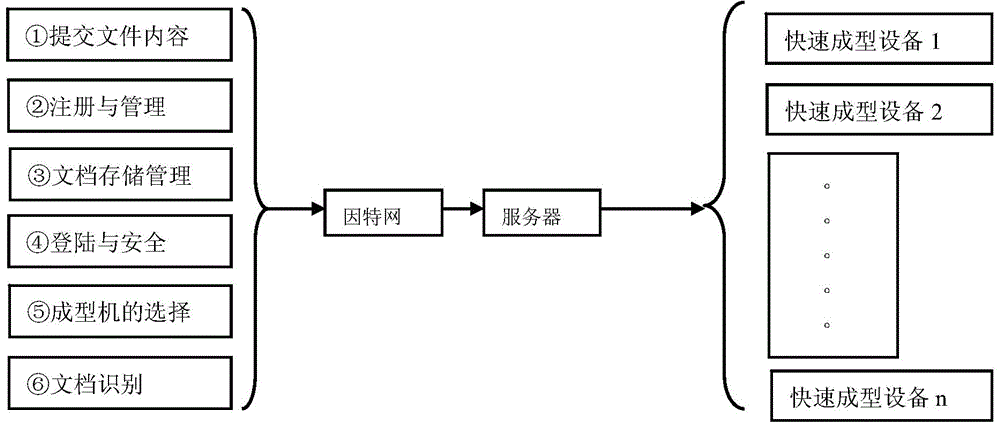

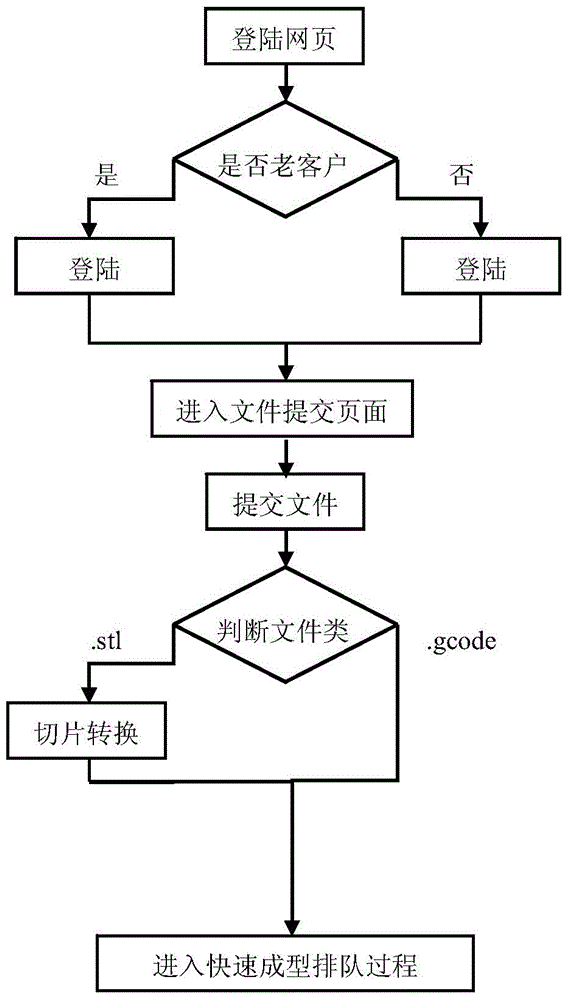

[0021] Server-to-client functions such as figure 1 Shown: The webpage of the client provides the content that the customer needs to choose. After the customer selects, the server reads the content in the form and text box through the background program and calculates and selects in the background. After the selection is completed, the file submitted by the user is processed. Inspect and finally submit the document in verification format to the rapid prototyping machine. The rapid prototyping machine communicates through the serial port, and each interruption will feed back the progress of the rapid prototyping machine and various parameters to the server, and feedback the customer's required molding time and other related information online.

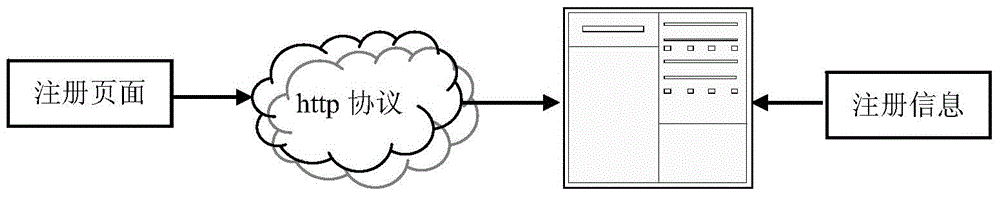

[0022] By reading the content selected or filled in by the customer in the text box or form, the server converts it into computer internal information and calls the MySQL database on the web page through the MySQL statement to automatica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com