Laser machining cover

A laser processing and metal cover technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of waste of space, increase labor costs, etc., and achieve the effect of reducing production costs, simple manufacturing process, and bright field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

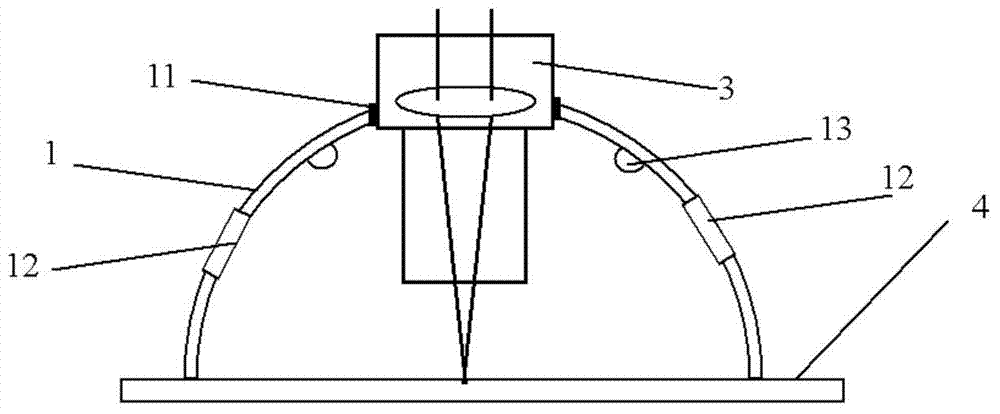

[0015] see figure 1 and figure 2 As shown, the present invention provides a laser processing cover, which includes:

[0016] A metal cover 1, which is hollow hemispherical, has a round hole 11 for fixing the laser head 3 in the middle part of the metal cover 1, and has a plurality of visible windows 12 on the side wall;

[0017] A plurality of goggle lenses 2 are fixed on the visible window 12 on the metal cover 1 .

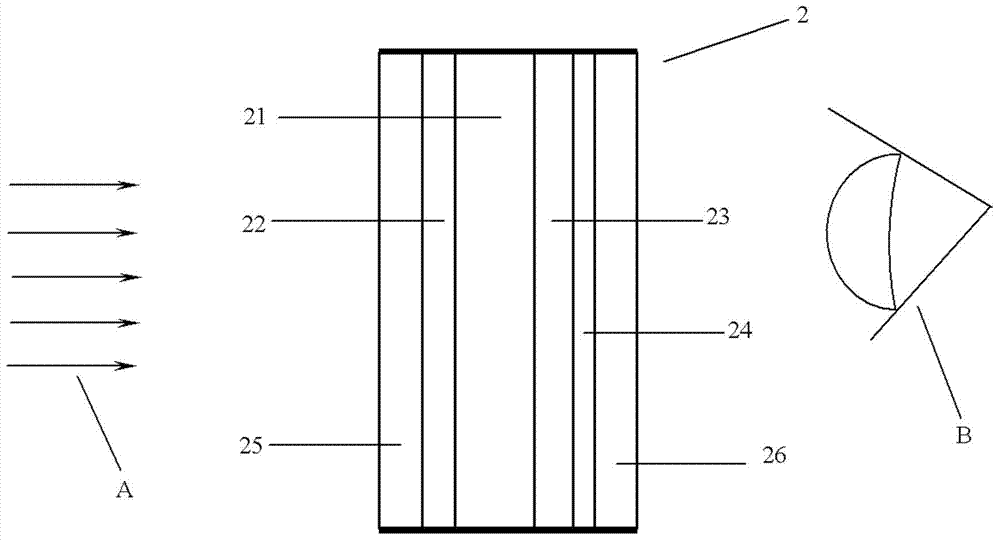

[0018] The structure of the goggle lens 2 is: a substrate 21, the material of the substrate 21 is transparent toughened phosphate glass, and the thickness is 1.0-1.2mm. The substrate 21 is vacuum-coated with the first coating 22 on the side facing the laser A by high-frequency sputtering. The material of the first coating 22 is an alternating sputtering structure of zirconia and silicon dioxide, and the number of layers of the two is alternately evaporated. 3-6, the thickness of each layer is 400-500nm. The first cover sheet 25 is covered on the coating film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com