Flux-cored welding wire and its preparation method and application

A technology of flux-cored welding wire and flux core, which is applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of steel quality, maintenance cost, and failure to meet the requirements of bending roll surfacing work, high-temperature hardness and long-lasting Poor performance and other problems, to achieve the effect of excellent surfacing metal properties, high temperature hardness, and long-lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

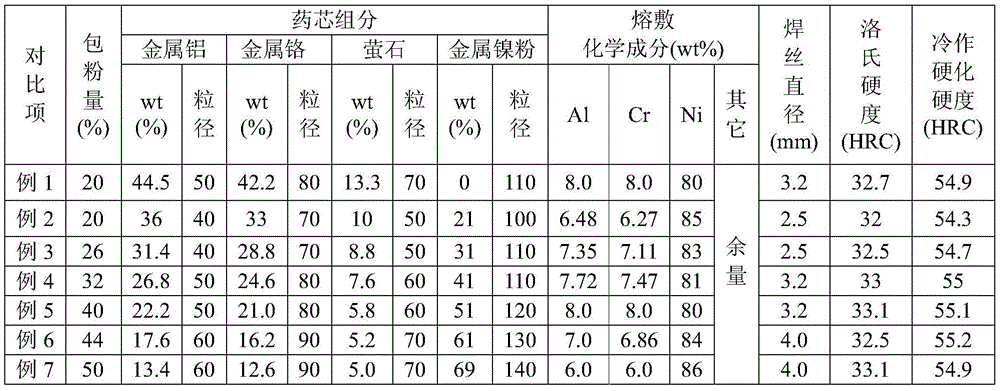

[0069] Example 1 The bending roller is repaired with a flux-cored wire with a diameter of Ф2.5mm

[0070] Welding material: use the welding wire prepared in Example 2 in Table 3, and use flux HJ107 for surfacing repair.

[0071] Technological process: Roll core preparation→flaw detection inspection→surfacing welding working layer→machining→finished product inspection; machining includes: turning and hardening treatment.

[0072] Specific operation of surfacing repair: turn the roll surface to a diameter of Ф414mm before welding; use submerged arc surfacing welding to make the roll surface diameter Ф422~425mm.

[0073] Surfacing specific process parameters:

[0074] Wire diameter: Ф2.5mm;

[0075] Power polarity: DC reverse connection;

[0076] Welding current: 220~260A;

[0077] Welding voltage: 28~32V;

[0078] Welding speed: 200~250mm / min;

[0079] Dry elongation of welding wire: 25~28mm;

[0080] The amount of post welding wire: 25 ~ 30mm;

[0081] Lap amount: 50-60...

Embodiment 2

[0084] Example 2 Repairing the bending roller with a flux-cored wire with a specification of Ф3.2 mm

[0085] Welding material: use the welding wire prepared in Example 4 in Table 3, and use flux HJ107 for surfacing repair.

[0086] Technological process: Roll core preparation→flaw detection inspection→surfacing welding working layer→machining→finished product inspection; machining includes: turning and hardening treatment.

[0087] Specific operation of surfacing repair: turn the roll surface to a diameter of Ф414mm before welding; use submerged arc surfacing welding to make the roll surface diameter Ф422~425mm.

[0088] Surfacing specific process parameters:

[0089] Wire diameter: Ф3.2m;

[0090] Power polarity: DC reverse connection;

[0091] Welding current: 260~320A;

[0092] Welding voltage: 29~33V;

[0093] Welding speed: 300~350mm / min;

[0094] Welding wire dry elongation: 28 ~ 30mm;

[0095] The amount of post welding wire: 28 ~ 30mm;

[0096] Lap amount: 50-...

Embodiment 3

[0099] Example 3 The bending roller is repaired with a flux-cored welding wire with a specification of Ф4.0mm

[0100] Welding material: Use the welding wire prepared in Example 6 in Table 3 with HJ107 flux for surfacing repair.

[0101] Technological process: Roll core preparation→flaw detection inspection→surfacing welding working layer→machining→finished product inspection; machining includes: turning and hardening treatment.

[0102] The specific process of surfacing welding repair: before welding, the roll surface is turned to a diameter of Ф414mm; the submerged arc surfacing welding working layer is used to make the roll surface diameter Ф422~425mm.

[0103] Surfacing specific process parameters:

[0104] Wire diameter: Ф4.0mm;

[0105] Power polarity: DC reverse connection;

[0106] Welding current: 350~420A;

[0107] Welding voltage: 29~33V;

[0108] Welding speed: 350~450mm / min;

[0109] Dry elongation of welding wire: 30~35mm;

[0110] The amount of post weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com