Multilayer hemp/carbon fiber composite board with hamburger structure and manufacturing process of multilayer hemp/carbon fiber composite board

A composite sheet and carbon fiber technology, applied in lamination, lamination devices, non-woven fabrics, etc., can solve problems such as bottlenecks in the mechanical properties of composite sheets and limit applications, and achieve excellent sound insulation effects, good shock absorption, and formability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) material selection and processing

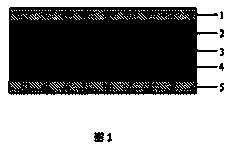

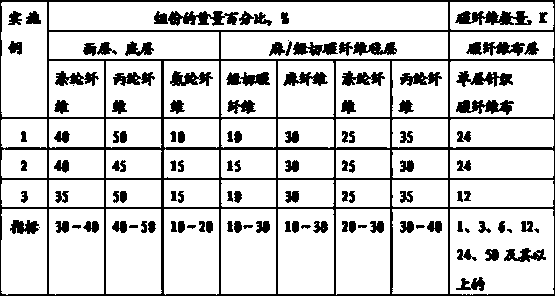

[0024] Both the surface layer 1 and the bottom layer 5 are made of polyester fiber, polypropylene fiber and spandex fiber and are made of three kinds of chemical fiber blending and needle punching; the weight percentage of each component is: polyester fiber 40%, polypropylene fiber 50%, spandex fiber 10% %.

[0025] Hemp / chopped carbon fiber felt layer Ⅰ2 and hemp / chopped carbon fiber felt layer Ⅱ4 are made of four kinds of fiber blends, namely chopped carbon fiber, hemp fiber, polyester fiber and polypropylene fiber, which are laid and needle-punched; the weight percentage of each component is: Chopped carbon fiber 10%, hemp fiber 30%, polyester fiber 25% and polypropylene fiber 35%.

[0026] Carbon fiber cloth layer 3 is a 24K single-layer knitted carbon fiber cloth after surface oxidation modification treatment; the specification K of carbon fiber yarn refers to the number of carbon fibers contained in a bundle of fiber yarns,...

Embodiment 2

[0041] (1) material selection and processing

[0042] Both the surface layer 1 and the bottom layer 5 are made of polyester fiber, polypropylene fiber and spandex fiber, and are made of three kinds of chemical fiber blending and laying; the weight percentage of each component is: polyester fiber 40%, polypropylene fiber 45%, spandex fiber 15% %.

[0043] Hemp / chopped carbon fiber felt layer I2 and hemp / chopped carbon fiber felt layer II4 are made of four kinds of fiber blends, namely chopped carbon fiber, hemp fiber, polyester fiber and polypropylene fiber, which are laid and needle-punched; the weight percentage of each component is: Chopped carbon fiber 15%, hemp fiber 30%, polyester fiber 25% and polypropylene fiber 30%.

[0044] Carbon fiber cloth layer 3 is a 24K single-layer knitted carbon fiber cloth after surface oxidation modification treatment.

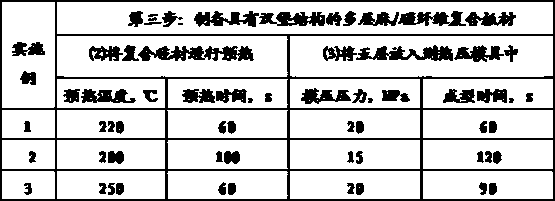

[0045] (2) Manufacturing process

[0046] Step 1: Prepare the Top and Bottom Layers

[0047] ⑴Use an opener to process...

Embodiment 3

[0059] (1) material selection and processing

[0060] Both the surface layer 1 and the bottom layer 5 are made of polyester fiber, polypropylene fiber and spandex fiber and are made of three kinds of chemical fiber blending and laying; the weight percentage of each component is: polyester fiber 35%, polypropylene fiber 50%, spandex fiber 15% %.

[0061] Hemp / chopped carbon fiber felt layer Ⅰ2 and hemp / chopped carbon fiber felt layer Ⅱ4 are made of four kinds of fiber blends, namely chopped carbon fiber, hemp fiber, polyester fiber and polypropylene fiber, which are laid and needle-punched; the weight percentage of each component is: Chopped carbon fiber 10%, hemp fiber 30%, polyester fiber 25% and polypropylene fiber 35%.

[0062] Carbon fiber cloth layer 3 is a 12K single-layer knitted carbon fiber cloth after surface oxidation modification treatment.

[0063] (2) Manufacturing process

[0064] Step 1: Prepare the Top and Bottom Layers

[0065] ⑴Use an opener to process t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com