Insulating luminescent material, solar battery back plate comprising insulating luminescent material, and solar battery component

A technology of solar cells and luminescent materials, which is applied in the field of solar cell backplanes and solar cell components, can solve problems such as the power reduction of solar cell components, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

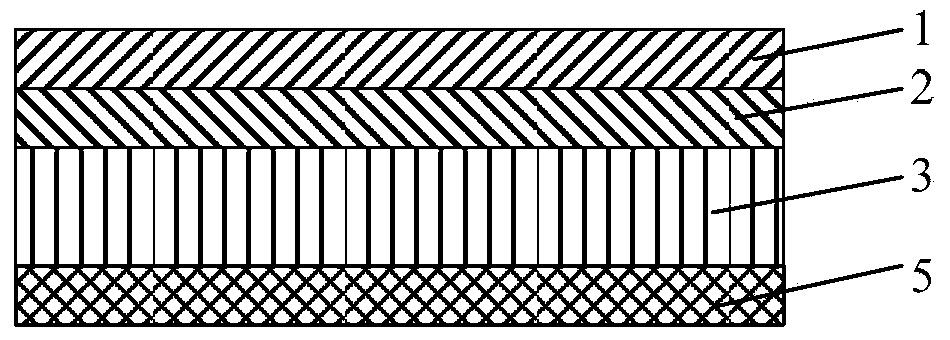

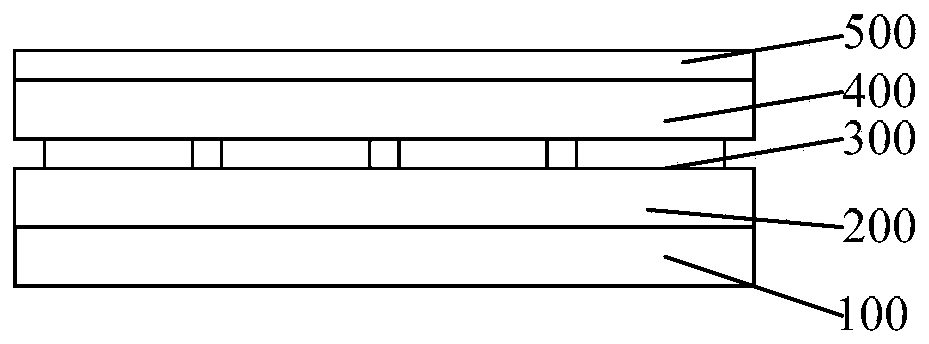

[0056] Polyethylene terephthalate resin (weight-average molecular weight 22000-24000, density 1.38-1.40g / cm 3 ), titanium dioxide powder and CaBaS 2 :MnO 2 , Eu 2+ The powder was melted at 280°C and casted on a metal drum to prepare an unstretched substrate with a thickness of 3 mm, then stretched 3 times longitudinally at 90°C, stretched 3 times transversely at 120°C, and heat-fixed at 220°C for 12 min. Anneal at 200°C for 12 minutes, and corona treatment is performed on the surface of the film to obtain a long-lasting luminous film with a thickness of 180 μm. PVDF with a thickness of 30 μm and a methacrylic acid polymer film with a thickness of 5 μm (weight average molecular weight 3000-4000 , Density 1.15~1.2g / cm 3 ), a long-lasting luminous film with a thickness of 180 μm, a methacrylic polymer film with a thickness of 5 μm (weight average molecular weight 3000-4000, density 1.15-1.2 g / cm 3 ) and an EVA film with a thickness of 25 μm are arranged sequentially to make t...

Embodiment 2

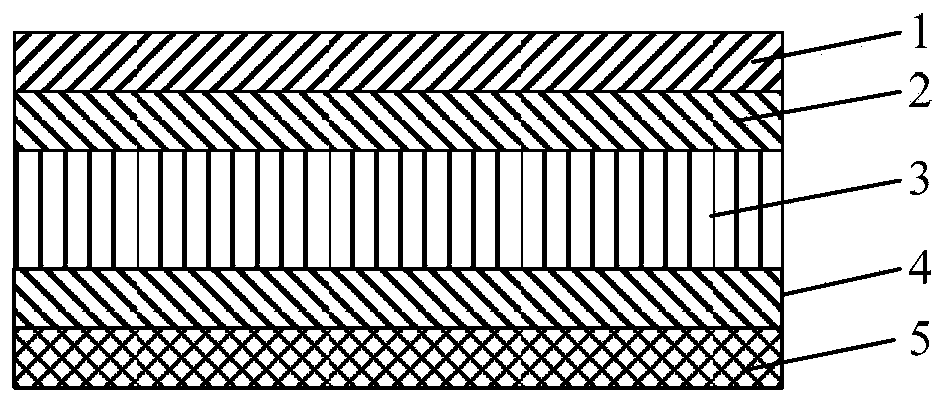

[0058] Polyethylene terephthalate resin (weight-average molecular weight 22000-24000, density 1.38-1.40g / cm 3 ), titanium dioxide powder and CaBaS 2 :MnO 2 , Eu 2+ The powder was melted at 280°C and casted on a metal drum to prepare an unstretched substrate with a thickness of 3.5 mm, then stretched 3.2 times longitudinally at 90°C, stretched 3.2 times transversely at 120°C, and heat-fixed at 220°C for 12 min , annealed at 200°C for 12min, and corona treatment was performed on the surface of the film to obtain a long-lasting luminescent film with a thickness of 185 μm. ~5000, density 1.15~1.2g / cm 3 ), a long afterglow luminous film with a thickness of 180 μm, a methacrylic polymer film with a thickness of 5 μm (weight average molecular weight 4000-5000, density 1.15-1.2 g / cm 3 ) and an EVA film with a thickness of 25 μm were arranged sequentially to make the solar battery back sheet of Example 2 by rolling.

Embodiment 3

[0060] High-density polyethylene (weight-average molecular weight 200,000-250,000, density 0.96-1g / cm 3 ), titanium dioxide powder and SrBaS 2 :MnO 2 , Eu 2+ The powder was melted at 280°C and casted on a metal drum to prepare an unstretched substrate with a thickness of 3.5 mm, then stretched 3.2 times longitudinally at 90°C, stretched 3.2 times transversely at 120°C, and heat-fixed at 220°C for 12 min , annealed at 200°C for 12min, and corona treatment was performed on the surface of the film to obtain a long-lasting luminescent film with a thickness of 185 μm. ~5000, density 1.15~1.2g / cm 3 ), a long afterglow luminous film with a thickness of 180 μm, a methacrylic polymer film with a thickness of 5 μm (weight average molecular weight 4000-5000, density 1.15-1.2 g / cm 3 ) and an EVA film with a thickness of 25 μm are arranged sequentially to make the solar battery back sheet of Example 3 by rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com