Heavy-load leveling crane

A crane and leveling technology, applied to cranes, mechanical equipment, load hanging components, etc., can solve the problems of crane operating environment, crane load reduction, crane rollover, etc., to reduce weight, improve performance, and increase bearing capacity. The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

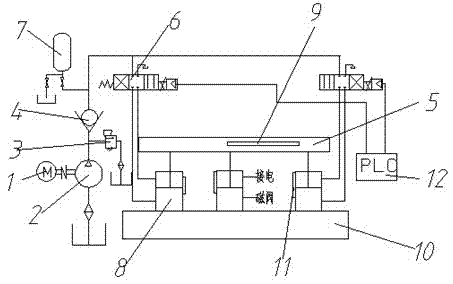

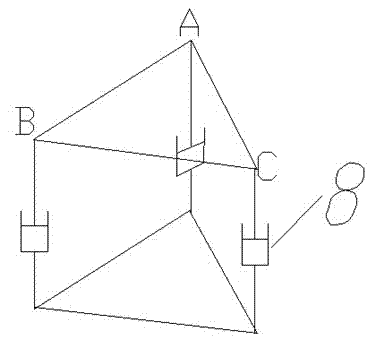

[0015] A heavy-duty leveling crane includes a power device, a working mechanism, a boom, a turntable and a chassis, which are all the same as the cranes in the prior art. The connecting structure of the chassis at its bottom and the turntable is the core part of the present invention, as figure 1 As shown, the turntable 5 is arranged on the chassis 10, and the chassis 10 is connected with the turntable 5 through a supporting mechanism. The supporting mechanism includes three hydraulic cylinder systems, and the hydraulic cylinder The system includes a hydraulic cylinder 8, a motor 1, a pump body 2, a one-way valve 4, an accumulator 7, a solenoid valve 6 and an ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com