Method for treating pickle wastewater

A treatment method and technology for wastewater, which are applied in the fields of food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It does not meet the strategic goals of energy conservation and emission reduction, increases the production cost of enterprises, etc., and achieves the effect of wide market application prospects, strong resistance to uneven settlement, and land saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

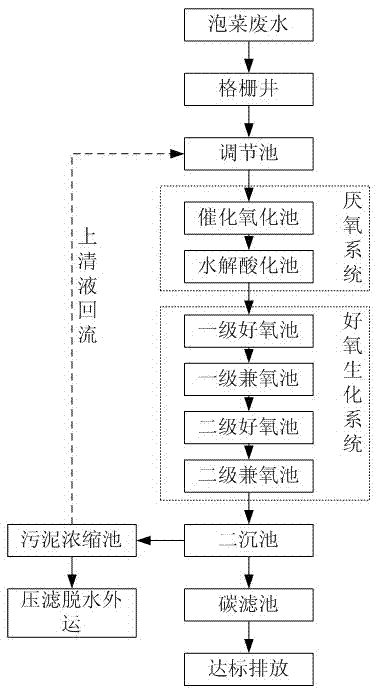

[0033] Such as figure 1 Shown, the processing method of this pickle waste water, comprises the steps:

[0034] (1) In the preparation stage, according to the characteristics of the discharged pickle wastewater, select, cultivate and domesticate the exclusive anaerobic, facultative and aerobic salt-tolerant bacteria that can adapt to the pickle wastewater, and use them in the corresponding treatment stage; specifically In other words, the steps of screening, cultivating and domesticating exclusive anaerobic, facultative and aerobic salt-tolerant bacteria are as follows:

[0035] (1a) Take kimchi wastewater and activated sludge from the original discharge site and add them to the bacterial culture tank to simulate actual living conditions for bacterial culture;

[0036] (1b) Screen surviving bacteria for cultivation and domestication, and irregularly add nutrients containing the three basic elements of carbon, nitrogen and phosphorus required for bacterial growth, such as flour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com