Automobile glass detergent

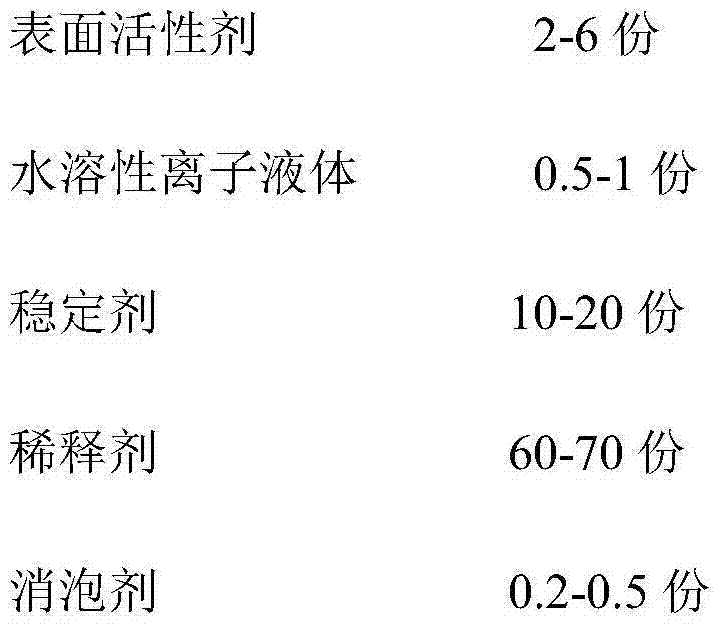

A technology for automotive glass and cleaning agent, which is applied in the direction of detergent compounding agent, detergent composition, organic cleaning composition, etc., and can solve problems such as endangering driving safety, unsuitable for popularization and application, and influence on light transmittance of front windshield glass. The effect of reducing friction and removing quickly and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 400g acrylic acid with 410g CH 3 O(CH 2 CH 2 o) 11 CH=CH 2 , add 10 g of chain initiator ammonium persulfate and react at 65° C. for 6 hours. After the reaction, adjust the pH to 7 with sodium hydroxide solution. After the reaction, evaporate the water contained therein to obtain the surfactant described in the present invention.

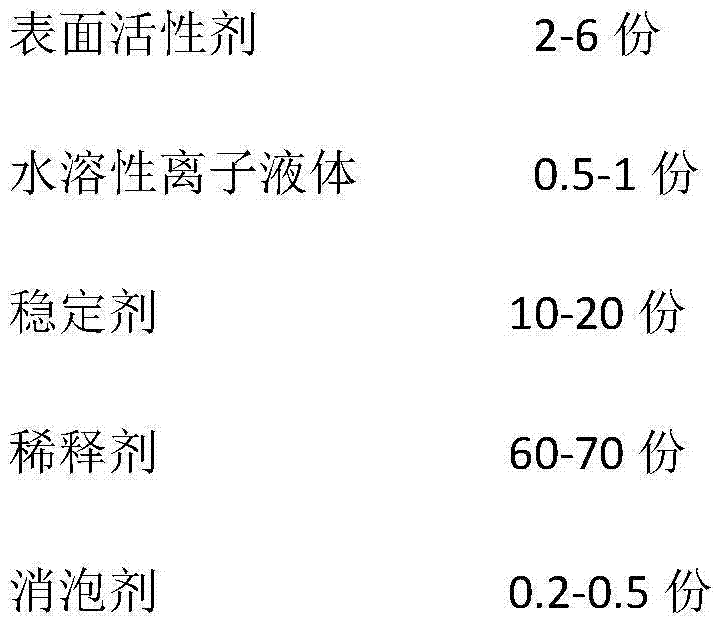

[0024] Add 700g of deionized water, 50g of copolymerized surfactant, 8g of [HBIm][BF 4 ] Ionic liquid, 200g ethanol, antifoaming agent PPG‐10005g, stir well at room temperature, and set aside. The pH value of the product is tested by precision pH test paper, the freezing point is tested by the SH / T0091 standard, the rubber swelling is tested by the national standard GB / T14832, the corrosion is tested by the national standard GB / T11143, and the cleaning effect is: residual traces after cleaning, streak residue, bright, anti-fouling Four grades are used for comprehensive evaluation. The test results are as follows:

[0025]

Embodiment 2

[0027] 300g acrylic acid with 600g CH 3 O(CH 2 CH 2 o) 15 CH=CH 2 , add 10 g of chain initiator ammonium persulfate and react at 65° C. for 6 hours. After the reaction, adjust the pH to 7 with sodium hydroxide solution. After the reaction, evaporate the water contained therein to obtain the surfactant described in the present invention.

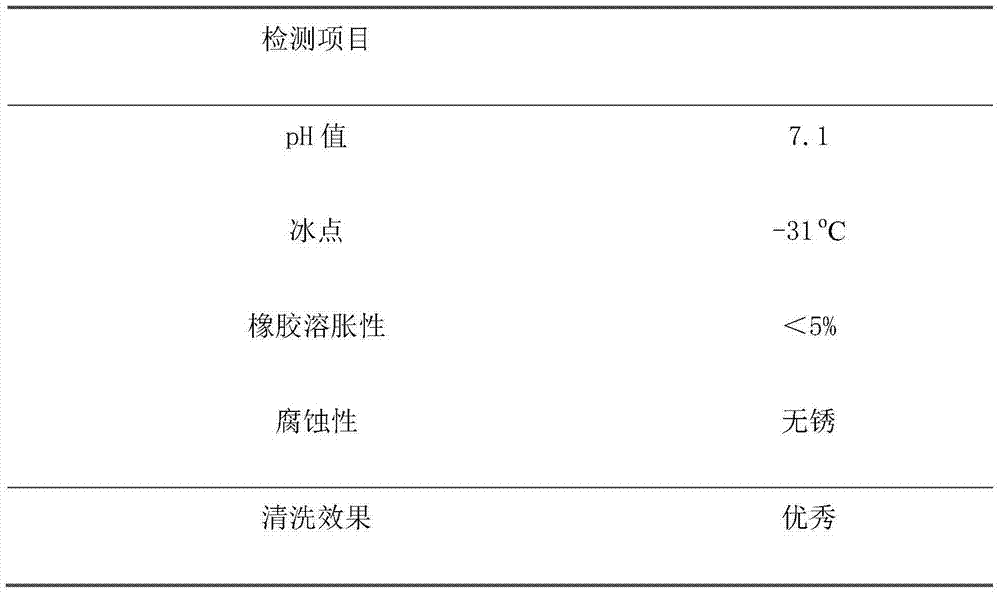

[0028] Add 1000g of deionized water, 80g of copolymerized surfactant, 8g of [HBIm][BF 4 ] Ionic liquid, 200g ethanol, antifoaming agent PPG‐24006g, stir well at room temperature, and set aside. The pH value of the product is tested by precision pH test paper, the freezing point is tested by the SH / T0091 standard, the rubber swelling is tested by the national standard GB / T14832, the corrosion is tested by the national standard GB / T11143, and the cleaning effect is: residual traces after cleaning, streak residue, bright, anti-fouling Four grades are used for comprehensive evaluation. The test results are as follows:

[0029] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com