Fuel pre-mixing type multi-spray-gun aluminium homogenizing furnace

A multi-lance, premixed technology, applied in gas fuel burners, furnaces, burners, etc., can solve problems such as difficulty in achieving the best combustion ratio of fuel and air, difficult control of combustion power, and difficult control of fuel delivery. , to achieve the effect of low cost of use, easy combustion, and reduction of heat loss in emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

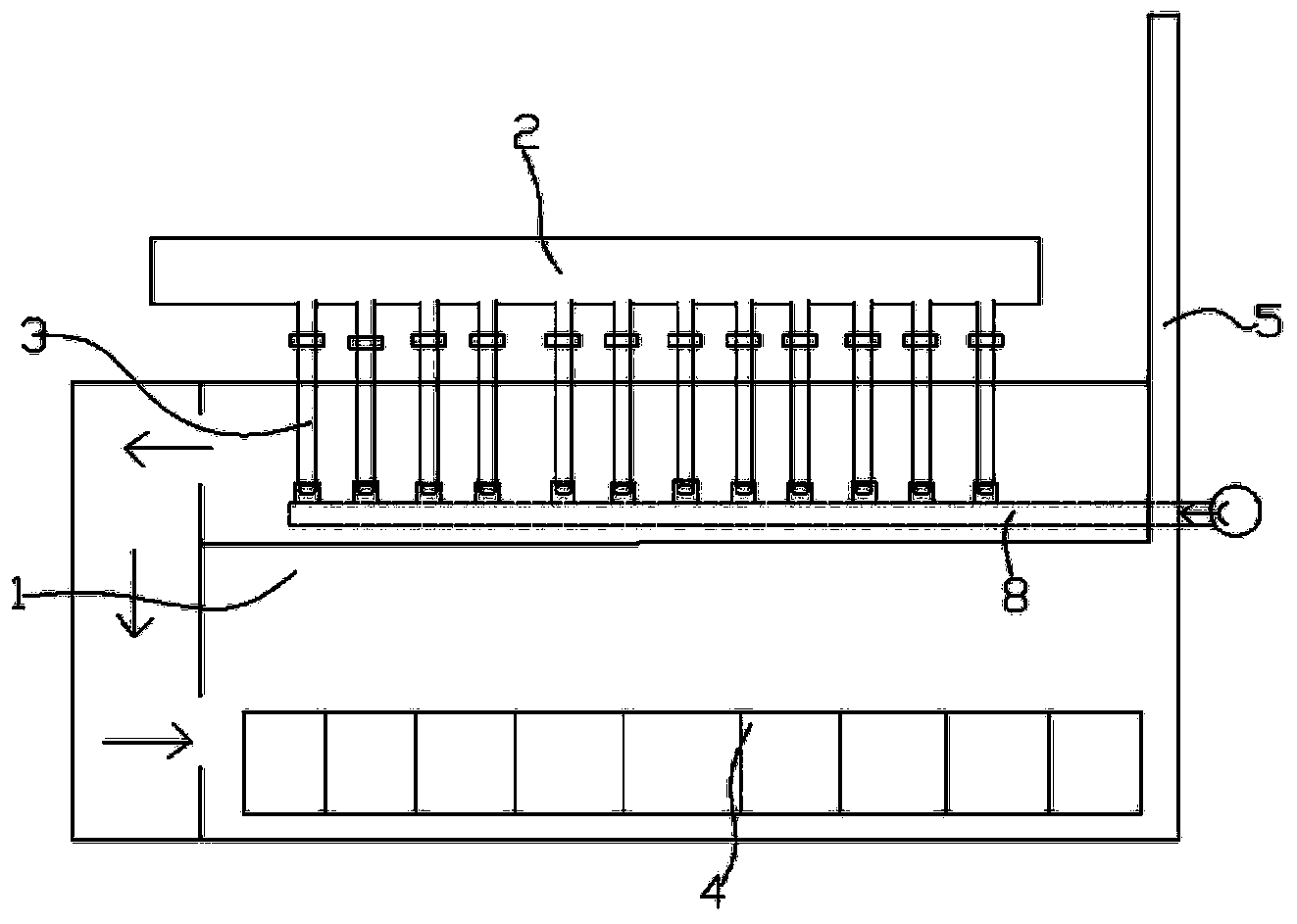

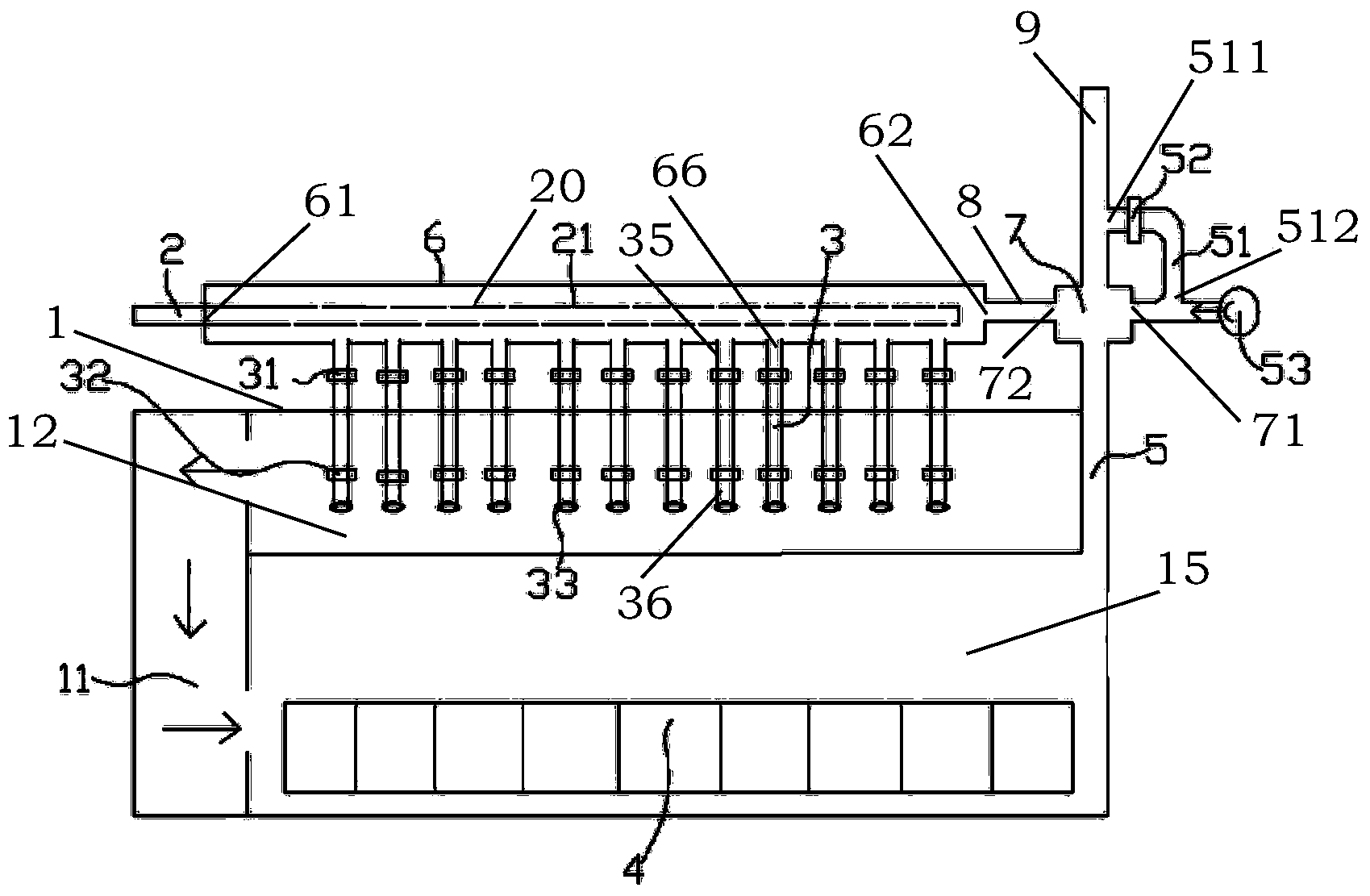

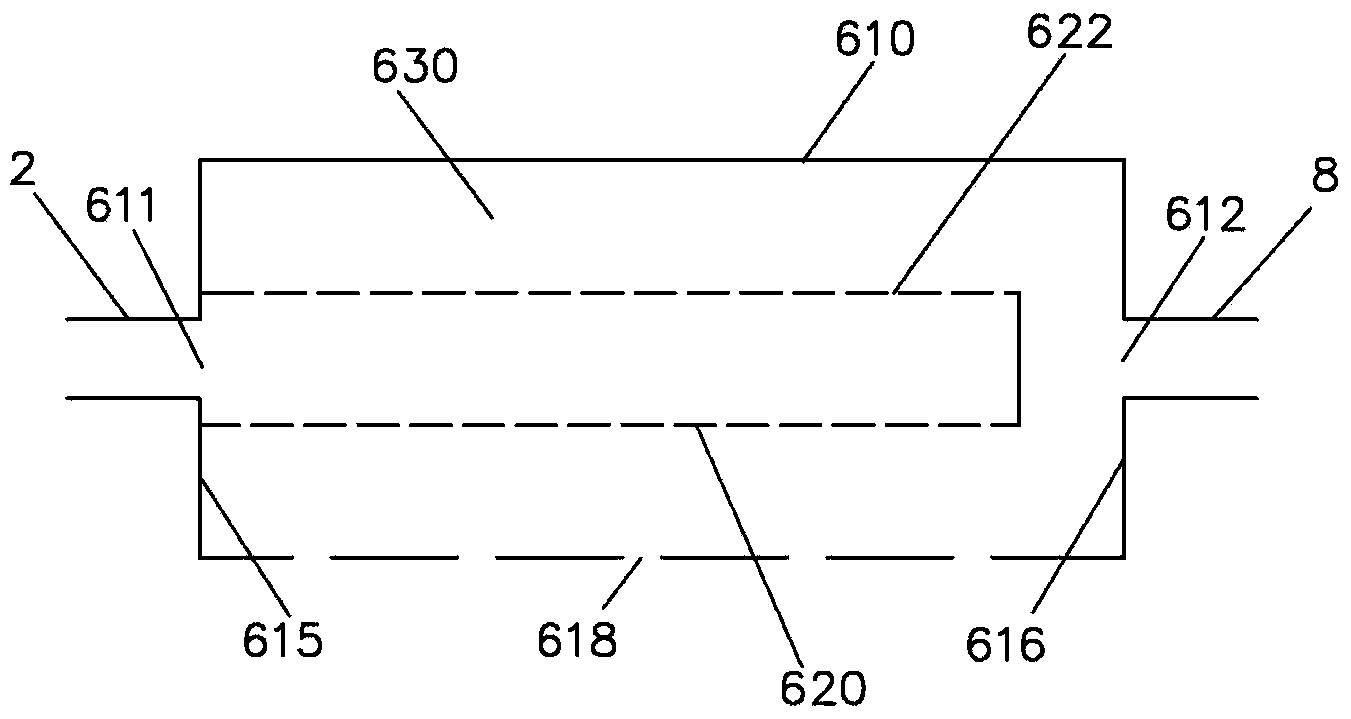

[0041] Please refer to figure 2 , the fuel premixed multi-spray gun aluminum homogeneous furnace provided by the present invention includes: furnace body 1, fuel delivery pipe 2, twelve combustion spray guns 3, flue gas pipeline 5, premix pipe 6, heat exchanger 7 and air Delivery pipe 8.

[0042] The furnace body 1 is provided with a furnace for heating the aluminum material 4 , and the furnace includes a combustion chamber 12 , a heat treatment chamber 15 and a communication channel 11 connecting the combustion chamber 12 and the heat treatment chamber 15 . The aluminum material 4 to be heat treated is accommodated in the heat treatment chamber 15 of the furnace. The flue gas pipe 5 is connected to the end of the heat treatment chamber 15 to discharge the generated flue gas to the chimney 9 .

[0043] Twelve combustion lances 3 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com