Large combined rare earth molten salt electrolyzer system

A combined technology of molten salt electrolysis, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of poor product quality and stability, difficulty in industrial production and application, cumbersome graphite tank masonry and other problems, so as to improve the service life and eliminate Participate in the electrolytic reaction, reduce the cell voltage and the effect of uneven electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

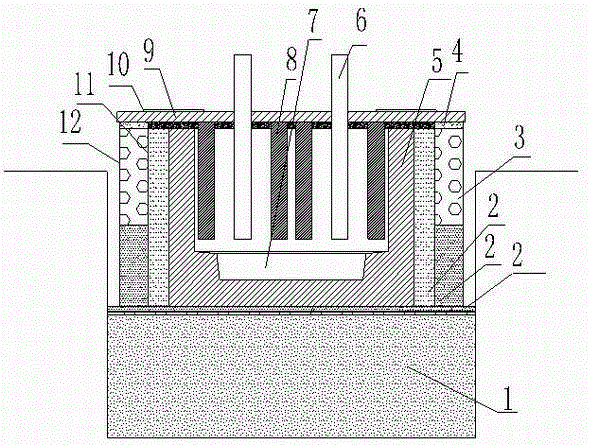

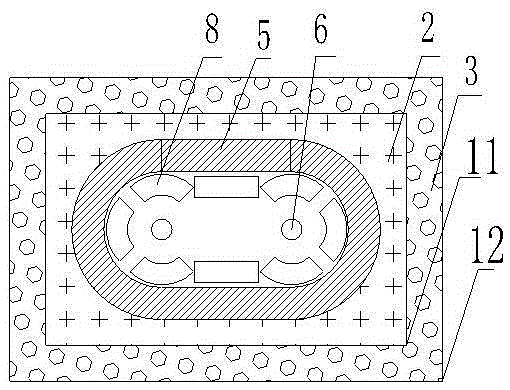

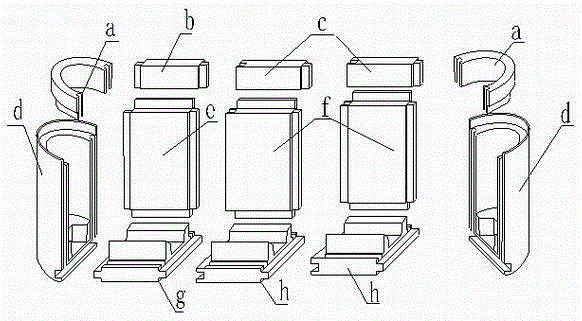

[0030] The present invention is a 15KA combined rare earth molten salt electrolytic cell system, which combines two semicircular side walls along side a with convex grooves on two first square side walls along side b to form a 15KA graphite cell Upper edge: respectively combine the grooves on the sides of the two semicircular side walls d with the convex grooves on both sides of the two first square side walls e, the convex grooves below the upper edge a of the two semicircular side walls, and The convex grooves along the bottom of b on the two first square side walls are combined to form the graphite groove side wall; the grooves below the two first square side walls e and the convex grooves on the side of the first base g are combined to form a graphite groove Bottom: set up an installation groove with length 1800*width 1300*depth 1400 on the level ground, fill the bottom of the installation groove with refractory cement 1, lay 20mm refractory material 2 on the top, and place...

Embodiment 2

[0033] Refer to attached Figure 8 , 9 The present invention is a 40KA multi-cathode power supply combined rare earth electrolytic cell, which combines two upper edges a of the semicircular side wall with two upper edges b of the first square side wall and four upper edges c of the second square side wall to form The upper edge of the graphite groove. The sides of two semicircular side walls d are respectively combined with two first square side walls e and four second square side walls f. The main body of the side wall of the graphite tank; the bottom of the graphite tank is composed of two semicircular side walls d The bottom of the base is combined with a first base g and two second bases h, and the upper edge of the combined graphite tank is combined with the main body of the side wall of the graphite tank and the bottom of the graphite tank to make it a large combined graphite tank overall.

[0034] Set up an installation groove with a length of 3500㎜*width of 2200㎜*de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com