Masonry method for rotary kilns

A technology of rotary kiln and rotary kiln, applied in the direction of rotary drum furnace, furnace, lining repair, etc., can solve the problems of loose prefabricated bricks, easy breaking of welding legs, time-consuming and cost-consuming, etc., to reduce maintenance costs and ensure integrity. , the effect of eliminating workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is described in further detail:

[0033] 【Example】

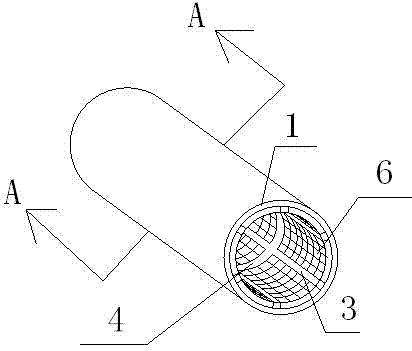

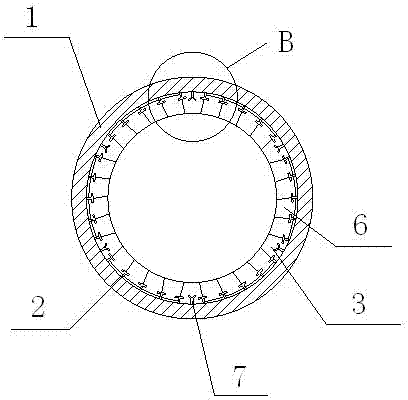

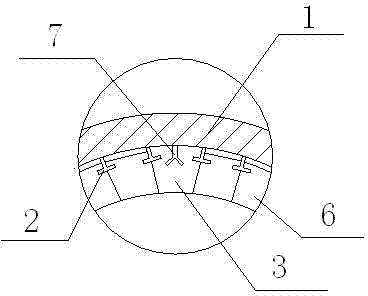

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the rotary kiln masonry structure and masonry method include the following steps:

[0035] A. Place the kiln body 1 horizontally, divide the inner surface of the kiln body 1, set a horizontal pouring area 3 every 60° along the circumferential direction on the inner surface of the kiln body 1, and the horizontal pouring area 3 extends through the entire kiln body in the axial direction 1, the inner surface of the kiln body 1 is provided with a plurality of longitudinal pouring areas 4 arranged at intervals along the axial direction, and the longitudinal pouring areas 4 extend 360° along the circumferential direction. The other regions of the vertical pouring zone 4 are the welding zone 5;

[0036] B. Locate and mark the welding points on the welding area 5. The welding points are used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com