Chemical analysis method for determination of zirconium content in alloy containing various interference elements

A technology for interfering elements and zirconium content, applied in the direction of chemical analysis by titration, etc., can solve the problems of restricting the engineering process, influence, and limitation of measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

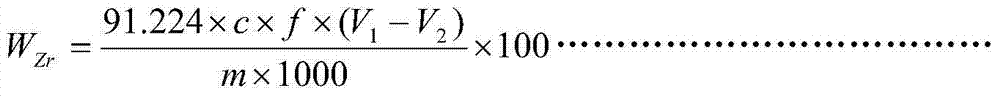

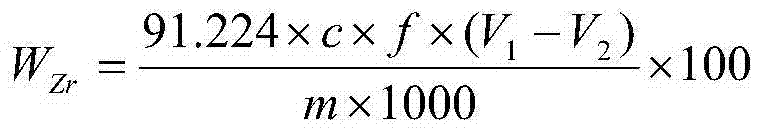

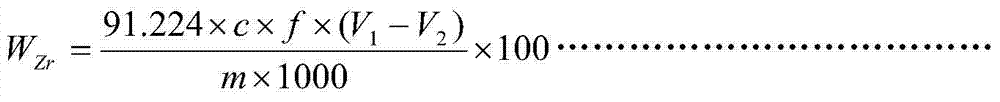

Embodiment 1

[0035] Example 1: Weigh 0.2g sample and place it in a platinum dish, add 2ml of nitric acid and slowly add hydrofluoric acid until the sample does not react; continue to add hydrofluoric acid, heat to dissolve, add 10ml of sulfuric acid, heat at low temperature until sulfuric acid fumes 3min; remove and cool slightly, rinse the dish wall with water, reheat to smoke, and cool down; wash the platinum dish with 200g / L sodium hydroxide; filter with medium-speed filter paper, wash with 10g / L sodium hydroxide; Dissolve the precipitate after washing in the previous step into a volumetric flask; take 10 ml of the pilot solution in the previous step, use xylenol orange as an indicator, and titrate with EDTA standard solution. Boil the solution again, if red appears in the solution, continue to titrate to yellow until the yellow color of the solution after boiling remains unchanged as the end point, and the mass fraction of zirconium obtained according to the formula is 45.54%, and the a...

Embodiment 2

[0049] Example 2: Weigh 0.2g sample and place it in a platinum dish, add 2ml of nitric acid and slowly add hydrofluoric acid until the sample does not react; continue to add hydrofluoric acid, heat to dissolve, add 10ml of sulfuric acid, heat at low temperature until sulfuric acid fumes 5min; remove and cool slightly, rinse the dish wall with water, reheat to smoke, and cool down; wash the platinum dish with 200g / L sodium hydroxide; filter with medium-speed filter paper, wash with 10g / L sodium hydroxide; Dissolve the precipitate after washing in the previous step into a volumetric flask; pipette 10 ml of the pilot solution in the previous step, use xylenol orange as an indicator, and titrate with EDTA standard solution. Boil the solution again, if red appears in the solution, continue to titrate to yellow until the yellow color of the solution remains unchanged as the end point after boiling, and the mass fraction of zirconium obtained according to the formula is 53.60%, and th...

Embodiment 3

[0050] Example 3: Weigh 0.2g sample and place it in a platinum dish, add 2ml of nitric acid and slowly add hydrofluoric acid until the sample does not react; continue to add hydrofluoric acid, heat to dissolve, add 10ml of sulfuric acid, heat at low temperature until sulfuric acid fumes 10min; remove and cool slightly, wash the dish wall with water, reheat to smoke, and cool down; wash the platinum dish with 200g / L sodium hydroxide; filter with medium-speed filter paper, wash with 10g / L sodium hydroxide; Dissolve the precipitate after washing in the previous step into a volumetric flask; pipette 10 ml of the pilot solution in the previous step, use xylenol orange as an indicator, and titrate with EDTA standard solution. Boil the solution again, if red appears in the solution, continue to titrate to yellow until the yellow color of the solution after boiling remains unchanged as the end point, and the mass fraction of zirconium obtained according to the formula is 55.50%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com