Processing method of extraction recombinant low-value fish protein

A fish protein and low-value technology, which is applied in the field of preparation of extruded and recombined surimi products, can solve the problems of high processing cost and difficult organization of surimi products, and achieve low cost of accessories, good operation stability, and improved The effect of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation process of extruded recombined fish meat protein, the steps are as follows:

[0038] (1) Mixing conditioning: Moisture content has a significant impact on the texture of extruded products. Mix hairtail surimi and soybean protein isolate in a weight ratio of 1:4, adjust the moisture content, sieve and rest overnight, so that the moisture of the raw materials is evenly distributed;

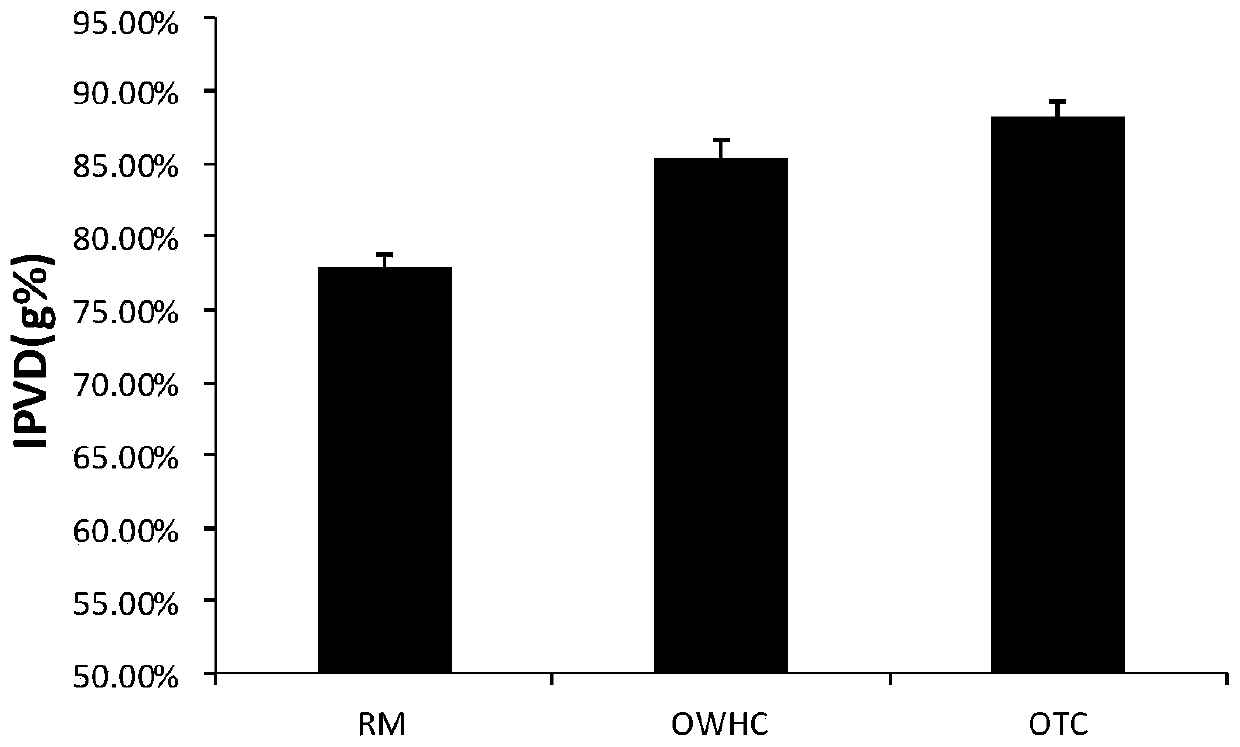

[0039] (2) Extrusion treatment: Extrusion treatment is the key to the whole process, which directly affects the physical properties, texture properties and nutritional properties of the extruded products. The outlet temperature of the extruder is controlled at 140°C-160°C, and the screw speed is 80rpm-120rpm, so that better texturization, water holding rate and protein in vitro digestibility can be obtained.

[0040] (3) Collect, bag and pack.

[0041] Water holding rate: take about 5g (W 1 ) Samples were placed in 100ml distilled water and allowed to stand for 30min. Cent...

Embodiment 1

[0048] Response surface methodology to optimize the extrusion process of surimi-soy protein isolate mixture:

[0049] Table 1 Response surface analysis test factor levels and codes

[0050]

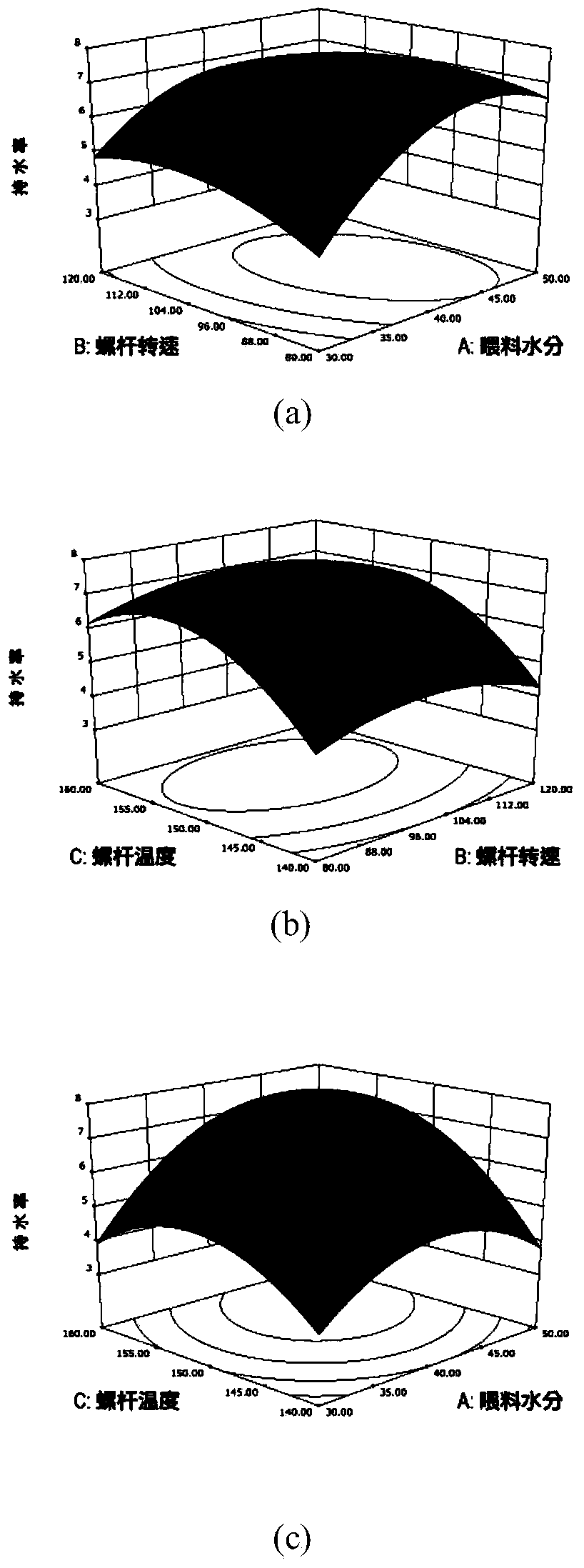

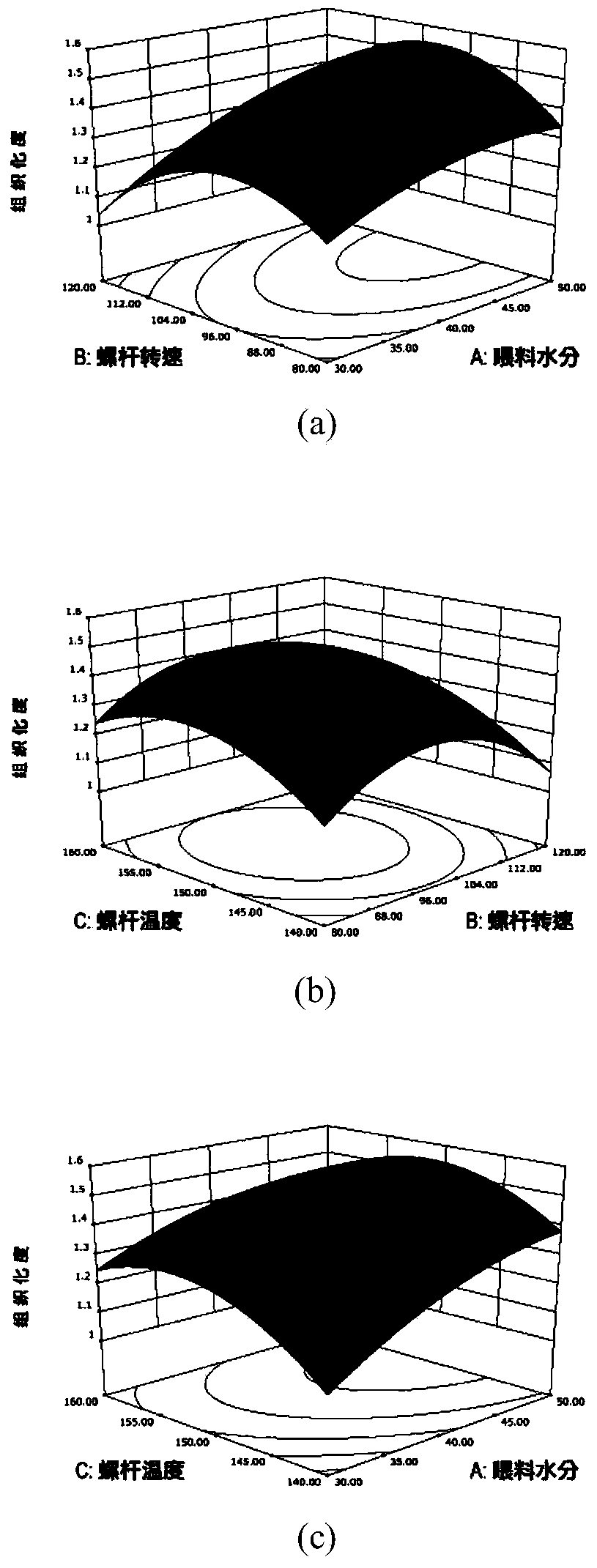

[0051] Using the Box-Behnken experimental design principle of the software Design-Expert8.0b, the moisture content (A), screw speed (B) and screw temperature (C) were used as independent variables to investigate the effect of process parameters on the extrudate texture and water holding capacity rate impact. The corresponding relationship between the standardized codes and actual values of each variable is shown in Table 1, the experimental design scheme and test results are shown in Table 2, and the analysis of the significance test results of the regression model coefficients is shown in Table 3. Multiple regression analysis was carried out according to the obtained data, and the multiple quadratic regression equation between the response variable (feed moisture, screw speed, scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com