Brazing method for DD5 single crystal alloy

A brazing method and alloy technology, which is applied in the field of brazing of DD5 single crystal alloys, can solve the problems that DD5 alloy connection technology has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

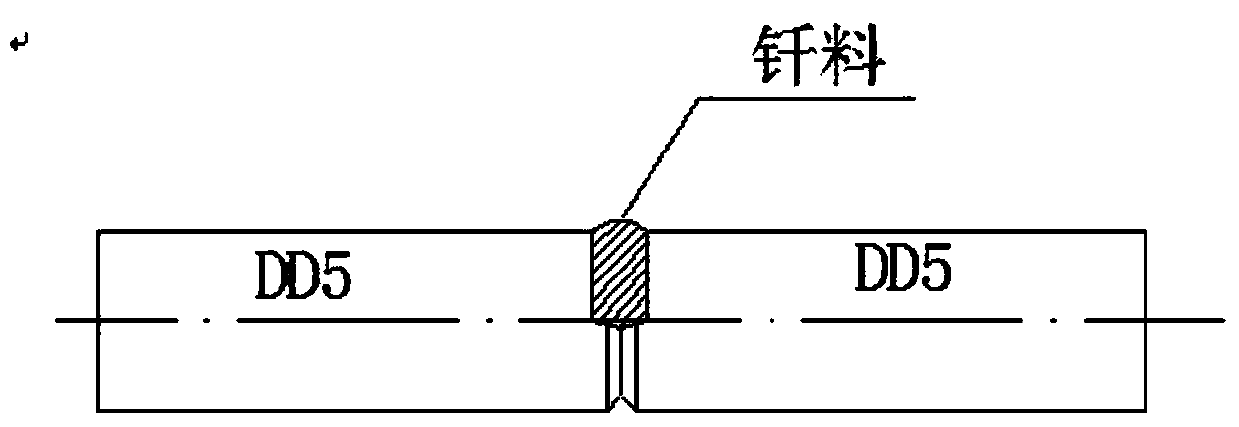

[0026] according to figure 1 The DD5 alloy sample is processed, with a diameter of Φ13 and a length of 33mm. Each tensile sample is formed by butt brazing of two above-mentioned samples.

[0027] (1) Sample cleaning

[0028] The surface of the sample to be welded is mechanically polished to remove the surface scale, and then the sample to be welded is cleaned with gasoline and alcohol in sequence to remove oil and dirt on the surface of the sample.

[0029] (2) Sample assembly

[0030] On the special fixture, the samples are assembled and positioned by superalloy sheet and energy storage spot welding method to ensure that the brazing gap between the samples is 0.1mm.

[0031] (3) Apply paint

[0032] Firstly, the powdery B-Ni55NbCoWCrAlSiMoTi solder (-150 mesh to -300 mesh) is mixed with a binder to form a paste solder, and the binder accounts for 8%. Then put the solder paste into the applicator, and finally apply the solder paste to the sample to be welded, and the amoun...

Embodiment 2

[0039] according to figure 1 Processing DD5 alloy sample, diameter Φ13, length 33mm. Each tensile specimen is butt-brazed from two of the above specimens.

[0040] (1) Sample cleaning

[0041] The surface of the sample to be welded is mechanically polished to remove the surface scale, and then the sample to be welded is cleaned with gasoline and alcohol in sequence to remove oil and dirt on the surface of the sample.

[0042] (2) Sample assembly

[0043] On the special fixture, the samples are assembled and positioned by superalloy sheet and energy storage spot welding method to ensure that the brazing gap between the samples is 0.1mm.

[0044] (3) Apply paint

[0045] Firstly, powdery B-Ni55NbCoWCrAlSiMoTi solder (-150 mesh to -300 mesh) is mixed with a binder to form a paste solder, and the binder accounts for 10%. Then put the solder paste into the applicator, and finally apply the solder paste to the sample to be welded, and the amount of solder coating should be able...

Embodiment 3

[0052] according to figure 1 Processing DD5 alloy sample, diameter Φ13, length 33mm. Each tensile specimen is butt-brazed from two of the above specimens.

[0053] (1) Sample cleaning

[0054] The surface of the sample to be welded is mechanically polished to remove the surface scale, and then the sample to be welded is cleaned with gasoline and alcohol in order to remove oil and dirt on the surface of the sample.

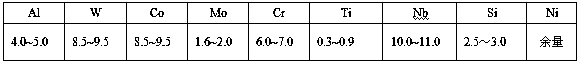

[0055] (2) Sample assembly

[0056] On the special fixture, the samples are assembled and positioned by superalloy sheet and energy storage spot welding method to ensure that the brazing gap between the samples is 0.1mm.

[0057] (3) Apply paint

[0058]Firstly, the powdery B-Ni55NbCoWCrAlSiMoTi solder (-150 mesh to -300 mesh) is mixed with a binder to form a paste solder, and the binder accounts for 12%. Then put the solder paste into the applicator, and finally apply the solder paste to the sample to be welded, and the amount of solder coating should be able...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com