Method for preparing vegetation concrete greening additive AB bacteria

A technology of greening additives and vegetation concrete, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of unstable pH value adjustment technology, decline in economic benefits, and withering, so as to increase beneficial bacteria and microorganisms and their populations, and strengthen plants Stress and disease resistance, the effect of promoting and regulating plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing vegetation concrete greening additive AB bacteria, the specific preparation steps are as follows:

[0029]1) Preparation of mature bio-organic bacteria material A:

[0030] In parts by weight, mix 280kg of crushed peanut shells, 0.1g of active enzyme agent, 0.2g of rot accelerator, and 1g of urea, and pile them into a pile with a width of 1.5-2 meters and a height of about 0.6 meters. , a pile of unlimited length, and use a stick to make air holes in the pile. The ambient temperature is above 15°C, the moisture content is controlled at 60-65%, and the materials are grouped by hand and just come out of the water; stack and turn the pile under natural open conditions for 10-30 days , When the pile temperature rises to 50°C, it starts to fall over once a day or once every other day. If the pile temperature exceeds 65°C, it will fall over again. The temperature is controlled below 70°C, too high a temperature will affect the nutrients. When the pile...

Embodiment 2

[0036] The present embodiment is basically the same as embodiment 1, and the only difference is that the weight component of the composition is preferably

[0037] 1) Biological organic bacteria material A:

[0038] In parts by weight, 290kg of crushed peanut shells, 0.2g of active enzyme agent, 0.25g of rot accelerator, and 1.5g of urea;

[0039] 2) Preparation of additive mixture B:

[0040] In parts by weight, 350g of biological organic bacteria material A, 350g of honeycomb cinder, 450g of peat soil, 9g of superphosphate, 8g of compound fertilizer, and 8g of urea;

[0041] 3) Preparation of vegetation concrete greening additive AB bacteria

[0042] In parts by weight, take 400g of additive mixture B, add 0.6g of carboxymethylcellulose CMC, 0.3g of agar powder, 0.6g of polyacrylamide, 0.02g of brassinolide, 0.02g of naphthaleneacetic acid, and 0.02g of indoleacetic acid , sodium nitrophenolate 0.02g, gibberellin 0.02g, triacontanol 0.02g.

Embodiment 3

[0044] The present embodiment is basically the same as embodiment 1, and the only difference is that the weight component of the composition is preferably

[0045] 1) Biological organic bacteria material A:

[0046] In parts by weight, 300kg of crushed peanut shells, 0.3g of active enzyme agent, 0.3g of rot accelerator, and 2g of urea;

[0047] 2) Preparation of additive mixture B:

[0048] In parts by weight, biological organic bacteria material A400g, honeycomb cinder 400g, peat soil 500g, superphosphate 10g, compound fertilizer 10g, urea 10g;

[0049] 3) Preparation of vegetation concrete greening additive AB bacteria

[0050] In parts by weight, take 500g of additive mixture B, add 0.7g of carboxymethylcellulose CMC, 0.5g of agar powder, 0.8g of polyacrylamide, 0.03g of brassinolide, 0.03g of naphthaleneacetic acid, and 0.03g of indoleacetic acid , sodium nitrophenolate 0.03g, gibberellin 0.03g, triacontanol 0.03g.

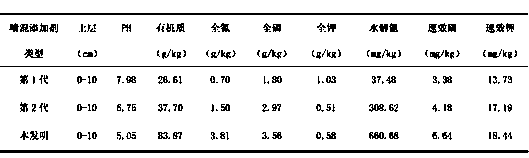

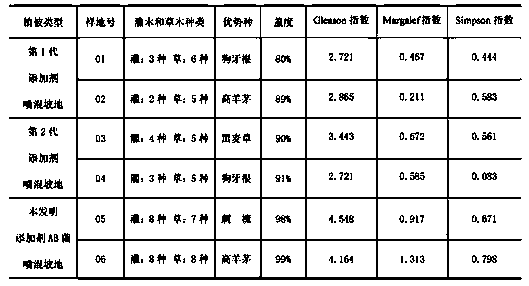

[0051] Adopt the first generation described in the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com