Transparent resin composition for led injection molding packaging

A transparent resin, injection molding technology, used in electrical components, circuits, semiconductor devices, etc., can solve the problems of yellowing, reduced luminous efficiency, and reduced adhesion

Inactive Publication Date: 2016-01-20

BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention is to provide a transparent resin composition for LED injection molding packaging, which has high heat resistance, yellowing resistance, and high transparency, and can solve the problem of epoxy resin molds for the existing chip-type LED packaging. Plastics are prone to yellowing, delamination, decreased adhesion, decreased mechanical properties, and decreased luminosity, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

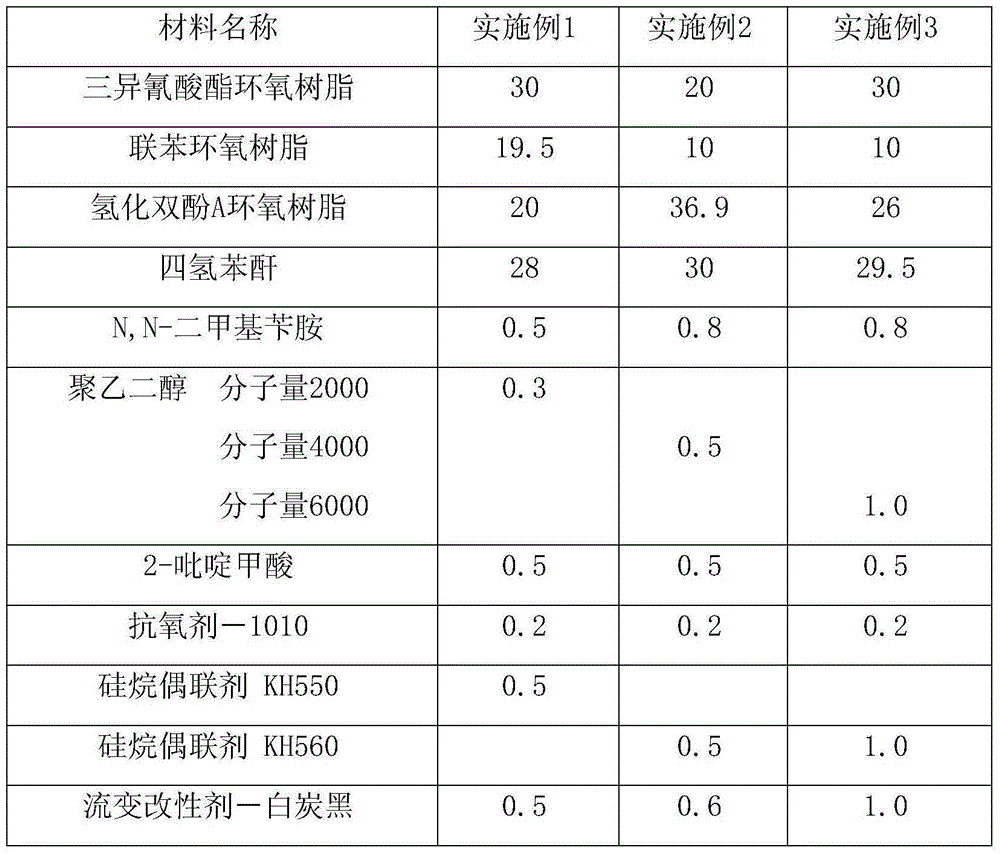

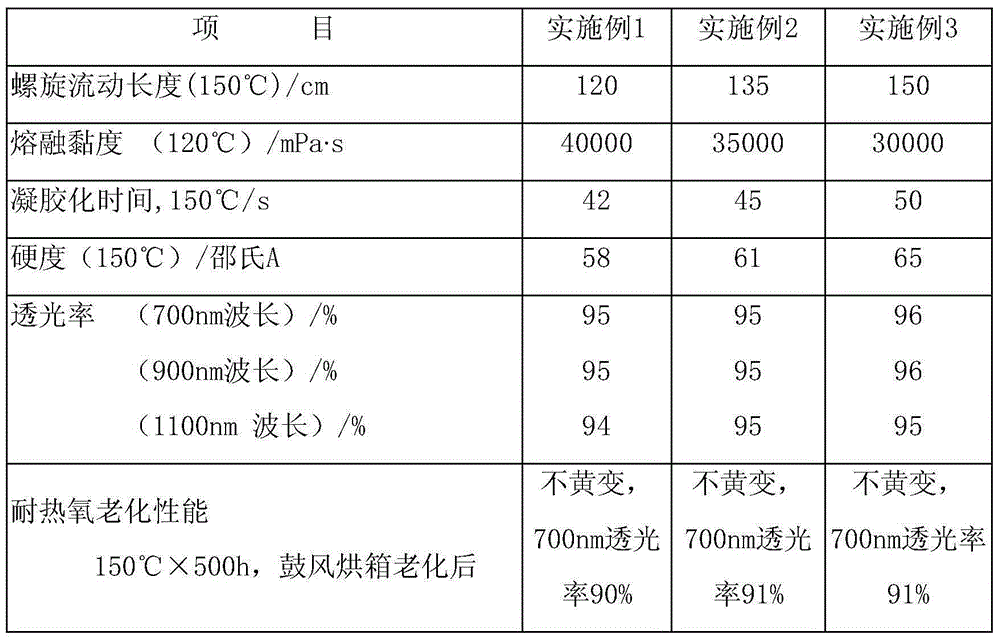

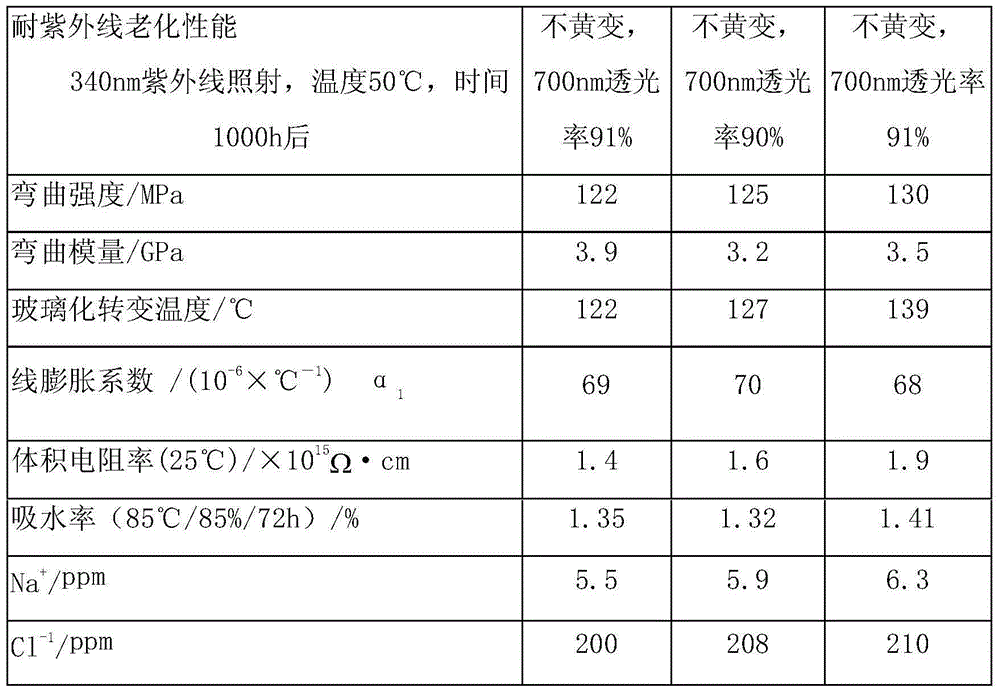

[0023] The formula and preparation technology of embodiment 1~3 are as shown in table 1, specifically as follows:

[0024] Table 1 Embodiment 1~3 formula and preparation technology (the amount of each raw material is calculated by mass percentage)

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a transparent resin composition for injection molding encapsulation of a light-emitting diode (LED), and belongs to the field of an LED encapsulation material. The composition is prepared from the following raw materials: 20-30wt% of triisocyanate epoxy resin, 10-20wt% of biphenyl epoxy resin, 20-40wt% of hydrogenated bisphenol A epoxy resin, 20-30wt% of curing agent, 0.1-1wt% of curing catalyst, 0.1-1wt% of antioxidant, 0.1-1wt% of silane coupling agent, 0.1-1wt% of chelating agent, 0.1-1wt% of release agent and 0.1-1wt% of rheology modifier in a mixing manner. The resin composition has the characteristics of being high in transparency, good in heat resistance and good in liquidity, and can well meet the requirements of an injection molding encapsulation technology of a patch LED.

Description

technical field [0001] The invention relates to the field of resin materials for LED encapsulation, in particular to a transparent resin composition for chip-type LED encapsulation used in an injection molding encapsulation process. Background technique [0002] At present, the development of LED is very rapid, and its application in display, lighting and other fields is increasing day by day. Traditional LED packaging mostly uses liquid epoxy resin, generally two components, A and B, and is packaged by potting process. Liquid epoxy resin is inconvenient to transport, use and store. Moreover, as the size of the LED decreases, the packaging form changes, and the packaging technology advances, the SMD packaging develops rapidly. [0003] At present, the packaging of SMD LEDs is mostly packaged by injection molding (transfer molding), and the injection molding package needs to use solid transparent epoxy resin molding compound. [0004] However, due to the long working time ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L63/00C08L63/02C08G59/42C08G59/20C08K13/02C08K5/544C08K5/5435H01L33/56

Inventor 杨明山程艳芳周颖胡晓东

Owner BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com