Spinning process of semicontinuous high-speed spinning machine

A technology of high-speed spinning and spinning technology, applied in the field of spinning technology, can solve the problems of pollution of winding device, inability to increase spinning speed, insufficient response of filaments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

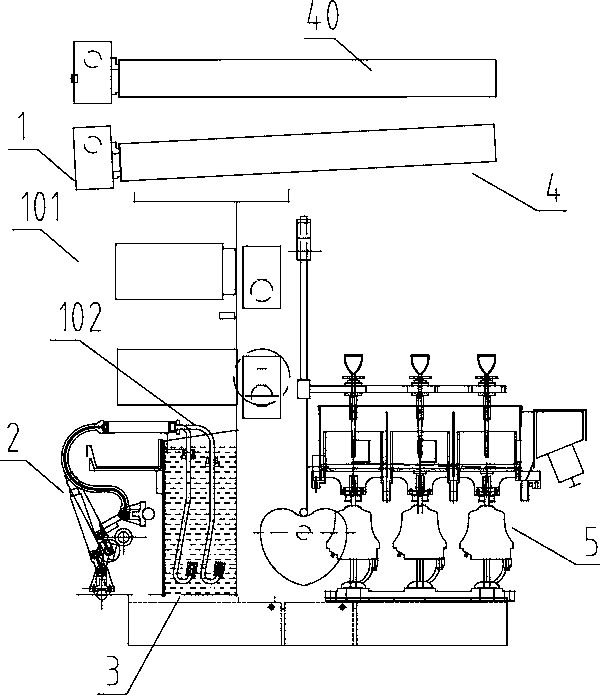

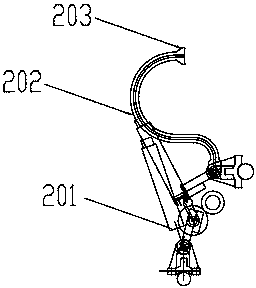

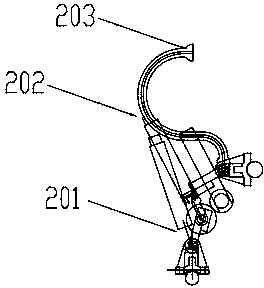

[0275] A spinning process of a semi-continuous high-speed spinning machine, comprising glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3 is completed, the spinning is completed by the spinning device 4, and the winding is completed by the winding device 5, and it is characterized in that: the spinning device 4 includes at least one operating surface relative to the spinning surface 101 102 is a spinning roll 40 arranged transversely. The forming part of the winding device 5 is located outside the area between the wallboards 6 on both sides of the frame 1 and on the other side opposite to the spinning surface 101. The winding device 5 It includes a wet cake winding device 51, and / or a wet drum winding device 52, and / or a wet twist winding device 53, and the glue supply device 2 and the winding device 5 are respectively located in the On the outside...

Embodiment 2

[0277] A spinning process of a semi-continuous high-speed spinning machine, comprising glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3 is completed, the spinning is completed by the spinning device 4, and the winding is completed by the winding device 5, and it is characterized in that: the spinning device 4 includes at least one operating surface relative to the spinning surface 101 102 is a spinning roll 40 arranged transversely. The forming part of the winding device 5 is located outside the area between the wallboards 6 on both sides of the frame 1 and on the other side opposite to the spinning surface 101. The winding device 5 It includes a wet cake winding device 51, and / or a wet drum winding device 52, and / or a wet twist winding device 53, and the glue supply device 2 and the winding device 5 are respectively located in the On the outside...

Embodiment 3

[0285]A spinning process of a semi-continuous high-speed spinning machine, comprising glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3 is completed, the spinning is completed by the spinning device 4, and the winding is completed by the winding device 5, and it is characterized in that: the spinning device 4 includes at least one operating surface relative to the spinning surface 101 102 is a spinning roll 40 arranged transversely. The forming part of the winding device 5 is located outside the area between the wallboards 6 on both sides of the frame 1 and on the other side opposite to the spinning surface 101. The winding device 5 It includes a wet cake winding device 51, and / or a wet drum winding device 52, and / or a wet twist winding device 53, and the glue supply device 2 and the winding device 5 are respectively located in the On the outside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com