Box type safety hollow heat preservation plate and manufacturing method and application thereof

A thermal insulation board and safety technology, applied in thermal insulation, building components and other directions, can solve the problems of discount of thermal insulation effect, increase of material and construction cost, etc., and achieve the effect of good sound insulation effect, simplified construction process and construction cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

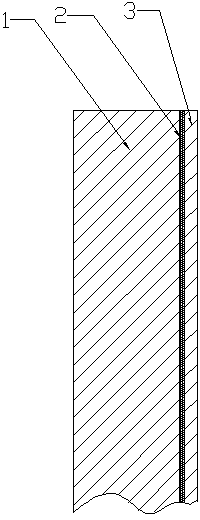

[0044] figure 1 Among them, the plastic or metal diaphragm (3) and the glass plate (1) are combined with an adhesive (2) to form a safety composite glass plate. The safety laminated glass sheet can be manufactured by continuous sizing and rolling lamination on the flat glass production line.

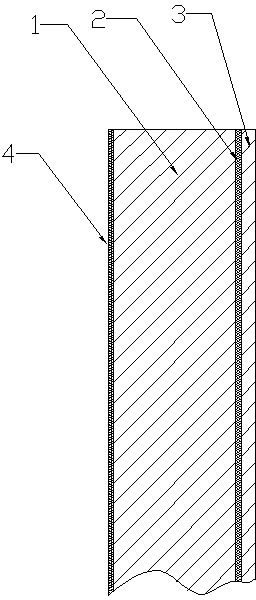

[0045] figure 2 Among them, the plastic or metal diaphragm (3) and the glass plate (1) are combined with an adhesive (2) to form a safety composite glass plate, and a protective layer (4) is attached to the glass surface of the glass plate (1) , to prevent ultraviolet rays from damaging the organic materials (organic adhesives, plastic molds, etc.) in the box-type safety hollow insulation board through the glass plate.

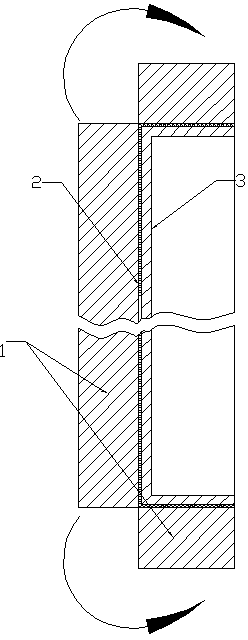

[0046] image 3 In the middle, the safety composite glass plate is bent along the peripheral folded plate (the glass plate is broken to keep the plastic or metal diaphragm intact) to form a grooved box bottom ( Figure 4Among them, the member A shown in the middle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com