A packaging method for semiconductor laser array single chip

A laser array and packaging method technology, applied in the field of lasers, can solve the problems of easy generation of electromigration and electrothermal migration, reduced reliability of semiconductor laser devices, easy oxidation of indium, etc., and achieves long service life, safe use, and elimination of mechanical errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

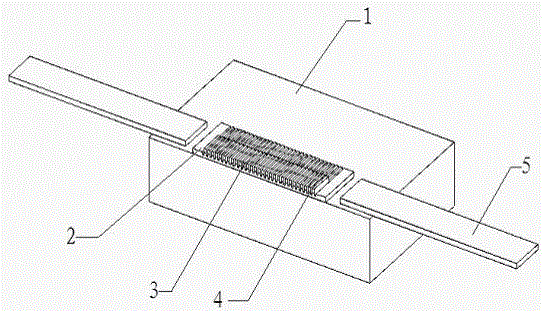

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0023] refer to figure 1 Shown, a kind of packaging method of semiconductor laser array single chip is characterized in that, comprises the following steps:

[0024] Step 1) Cut the aluminum nitride heat sink 2 according to the size of the bar of the semiconductor laser, for example, the size of the bar is 10×2mm2, and the size of the aluminum nitride heat sink 2 is 12×4mm2;

[0025] Step 2) Solder the aluminum nitride heat sink 2 and the oxygen-free copper heat sink 1 together with solder, the longitudinal front of the aluminum nitride heat sink 2 is aligned parallel to the front of the oxygen-free copper heat sink 1, and the aluminum nitride heat sink 2 The longitudinal and lateral dimensions of the semiconductor laser bar are much larger than the cavity length and width of the semiconductor laser bar. According to the arrangement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com