Automatic welding machine for chains

An automatic welding machine and chain technology, applied in welding accessories, welding equipment, welding equipment and other directions, can solve the problems of uneven weld size of welded parts, inability to meet production capacity requirements, and impact on the quality of the entire chain, so as to improve welding efficiency, Ensure assembly accuracy and quality, and ensure uniform, beautiful and firm welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

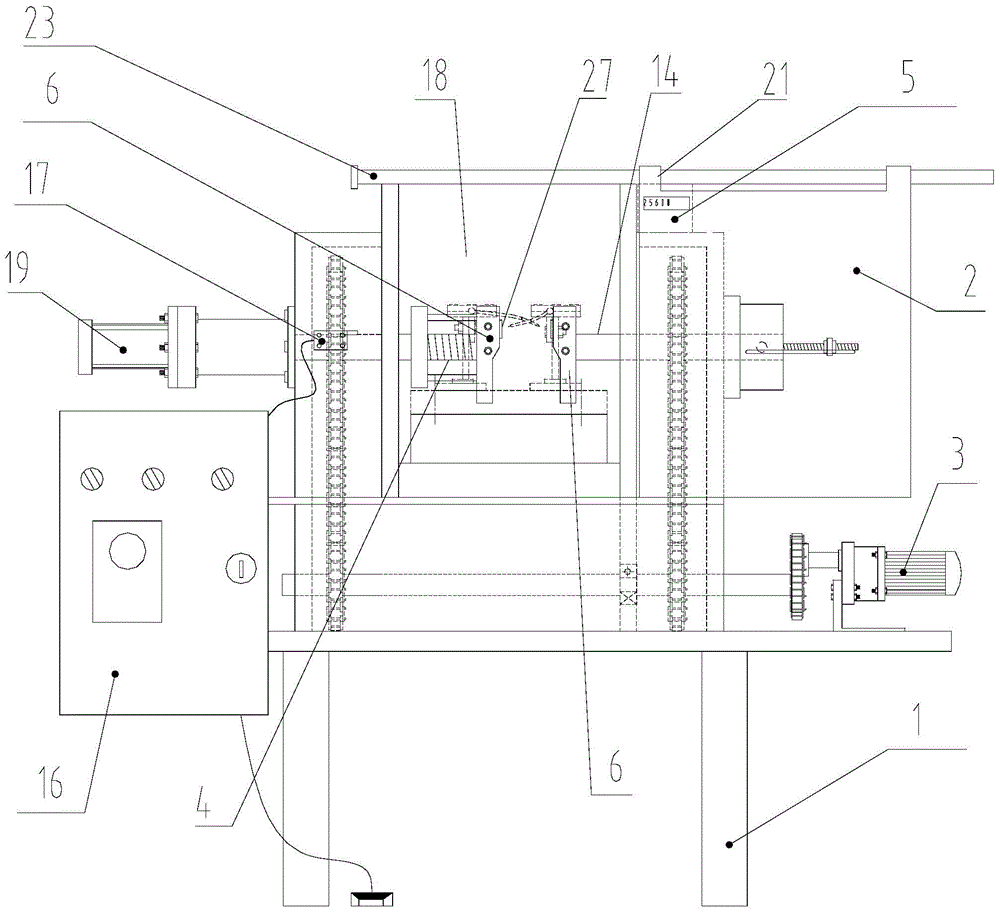

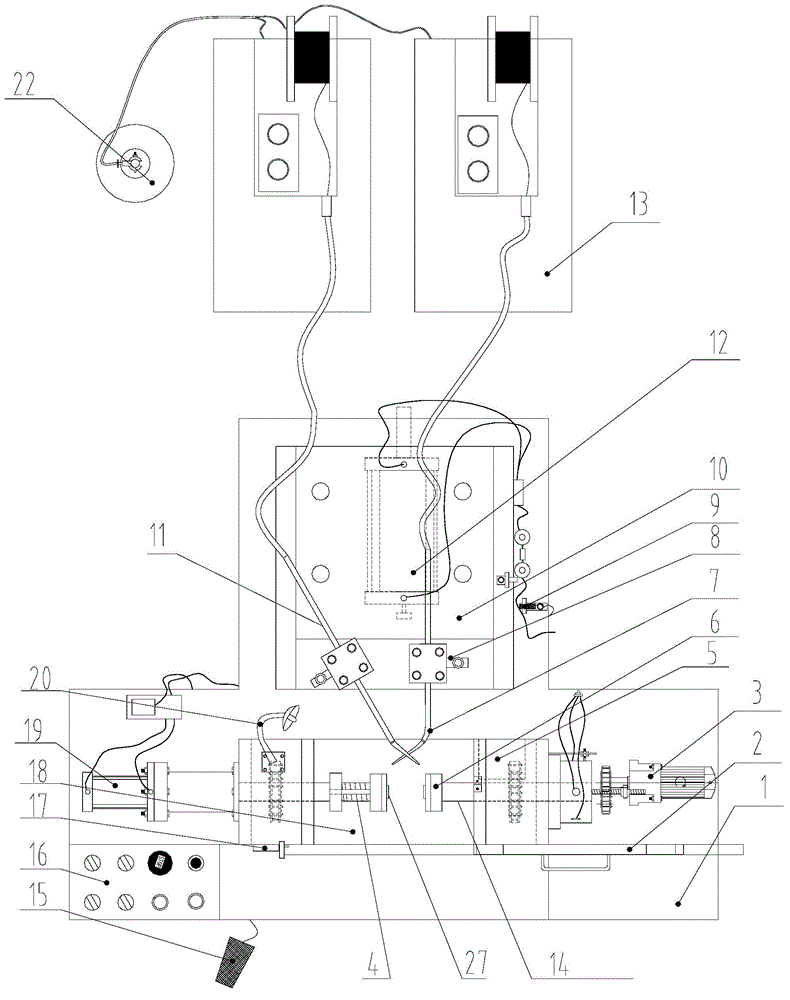

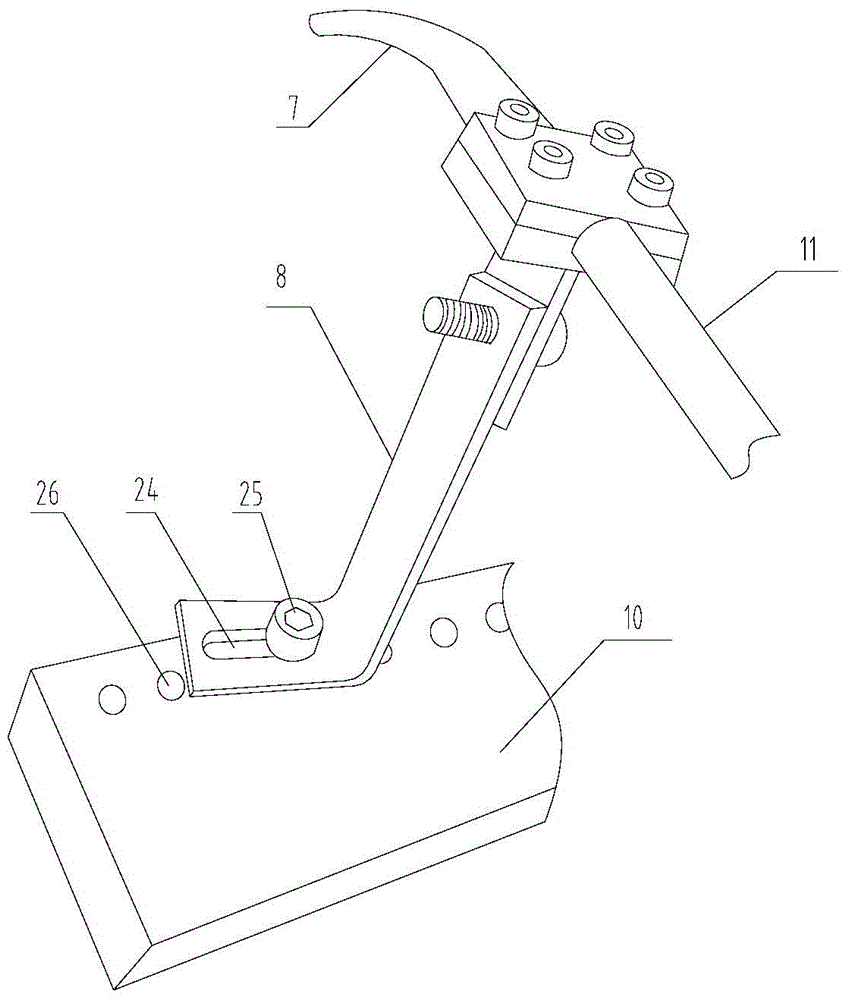

[0023] see figure 1 , figure 2 and Figure 4 , the chain automatic welding machine that present embodiment provides, comprises frame 1, is provided with positioning clamping system, transmission system, welding system and electric control system on frame 1, and positioning clamping system comprises clamping cylinder 19, the first rotation Rod 4 and the second rotating rod 14, the first rotating rod 4 and the second rotating rod 14 are coaxially arranged oppositely in the left and right directions, and a section area opposite to the first rotating rod 4 and the second rotating rod 14 forms a welding workbench 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com